Batteries

Battery technology as the driving force behind an array of innovation: Leading the development and production of next-generation batteries you can use with confidence

Batteries play an indispensable role in countless applications, from smartphones and electric mobility to renewable energy storage. The spread of AI is driving up electricity consumption in data centers, and although use of renewable energy is advancing, fluctuating output makes large-scale energy storage systems (ESS) essential. At the same time, there’s strong demand for the development of next-generation batteries that can be used safely and reliably.

Hioki provides comprehensive measurement solutions covering performance evaluation in battery R&D, quality inspections during production, and monitoring during use. These solutions help boost safety and performance while lowering costs.

Research and Development

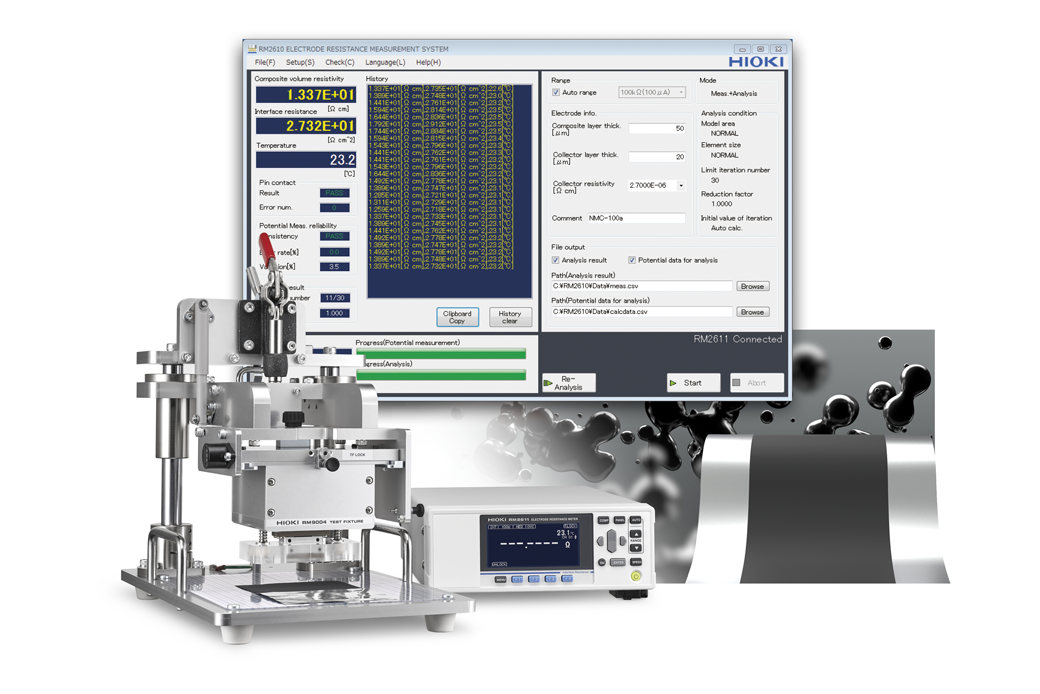

Battery R&D encompasses three domains:

- Materials development: The most critical area, directly linked to battery safety, performance, and cost

- Cell development: Optimizing the combination of materials and internal structure to unlock the potential of battery materials

- Pack development: Optimizing charge/discharge and thermal control to maximize overall performance

Hioki leverages its proprietary electrical measurement technologies to support the advancement of next-generation high-performance batteries by providing evaluation tools tailored to each of these domains.

Main products

Manufacturing

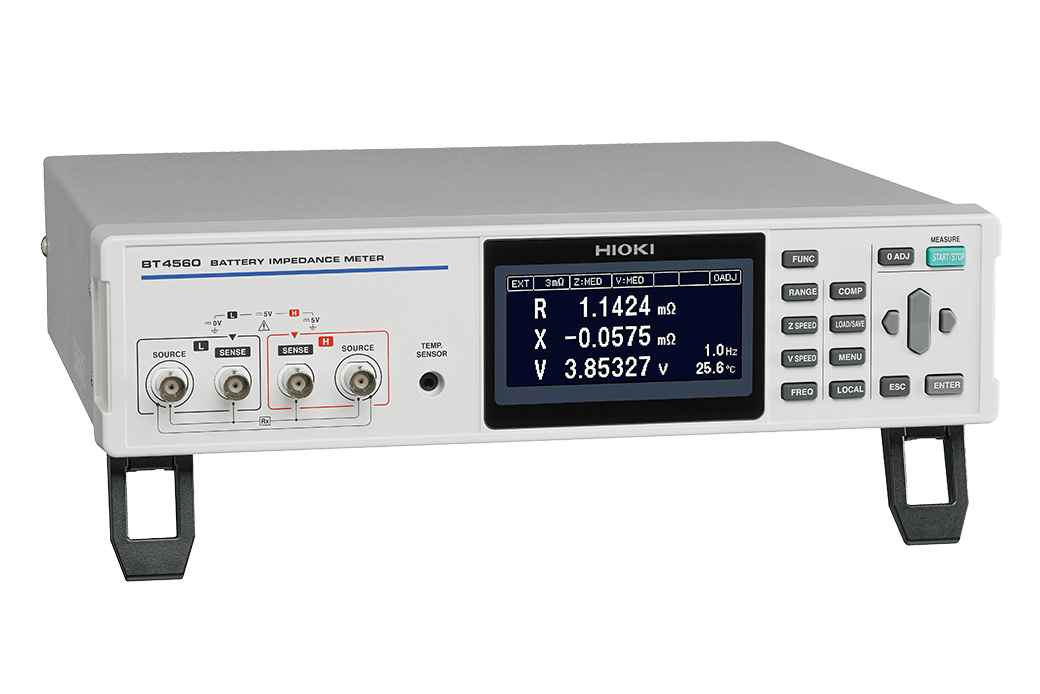

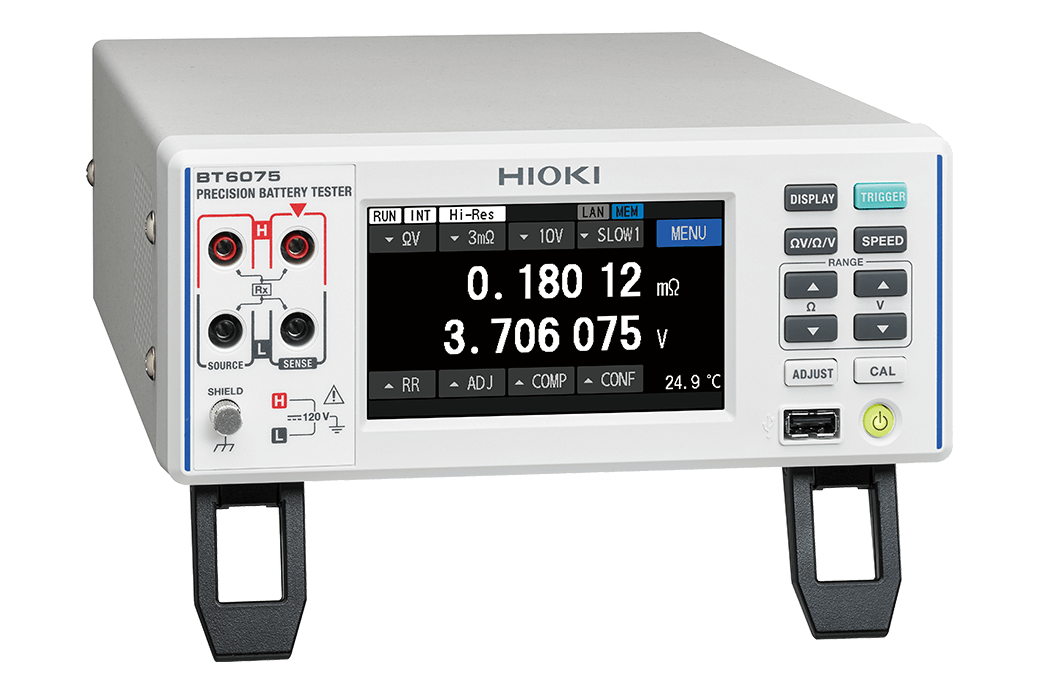

Process optimization and rigorous quality inspections are indispensable to ensure battery performance and safety. Electrical property testing is particularly important. Hioki’s battery testers, which are capable of measuring internal resistance (an essential indicator of battery condition), have become the de facto standard in the industry. We also provide high-precision DC voltmeters and insulation resistance testers that enable early detection of internal short circuits, further contributing to improved battery safety.

Main products

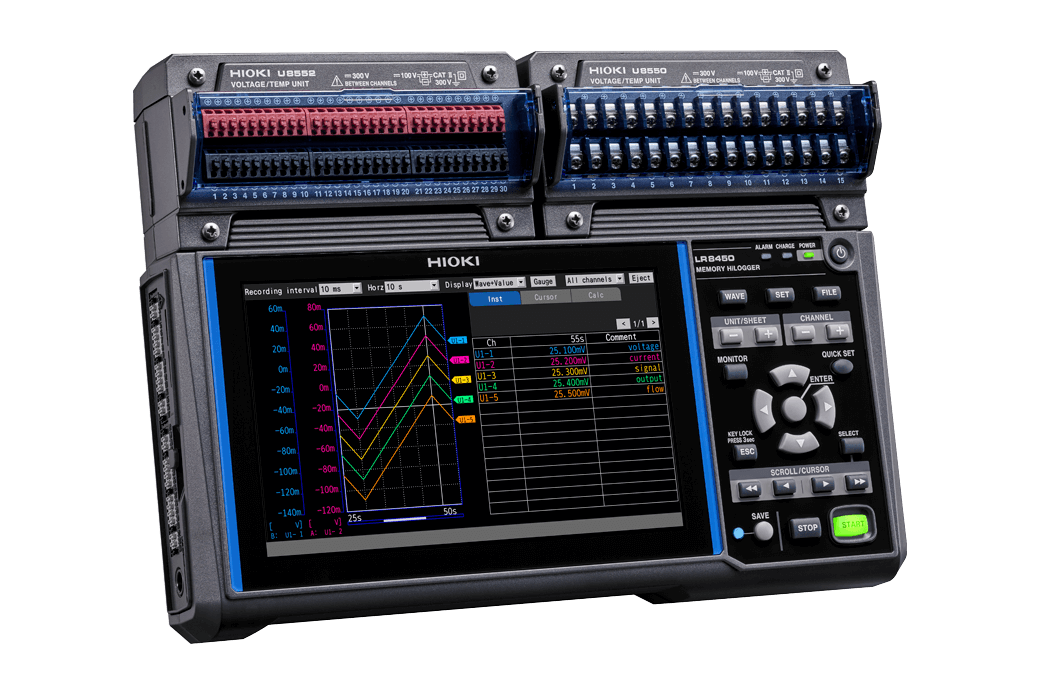

Quality assurance and maintenance

Batteries shipped to the market are expected to operate reliably for long periods of time—10 years in EVs and 20 years in emergency power supplies or ESS. Repeated charging and discharging alters their internal state, raising the risk of performance degradation or thermal runaway from internal short-circuits. Ensuring safe use requires both manufacturer quality assurance and proper on-site maintenance.

Hioki’s battery testers are designed to minimize the impact of noise that could compromise measurement accuracy, enabling precise assessment of battery condition through measurement of internal resistance and open-circuit voltage.