Product Jan. 07, 2020 Nagano, Japan

Hioki Launches the Battery Cell Voltage Generator SS7081-50

Easily and Accurately Evaluate Battery Management Systems Used with Lithium-Ion Battery Packs

Instrument Simulates Batteries so Users can Efficiently Build Testing Environments

Hioki is happy to announce the launch of the Battery Cell Voltage Generator SS7081-50 in March 2020.

The SS7081-50 is a 12-channel generator and measuring instrument that can easily and accurately evaluate the performance of battery management systems (BMSs) used in lithium-ion battery packs1 found in electric vehicles (xEVs) and storage batteries (energy storage systems [ESSs] and uninterruptible power systems [UPSs]).

Battery Cell Voltage Generator SS7081-50

Battery Cell Voltage Generator SS7081-50

As a simulated battery and voltage generator, the device facilitates performance and safety evaluation by making it possible to efficiently build an environment for testing parameters that would be difficult to reproduce with actual batteries, power supplies, or electronic loads.

In addition, the instrument provides high-precision voltage and current measurement capability so that researchers and developers can evaluate increasingly sophisticated BMS functionality.

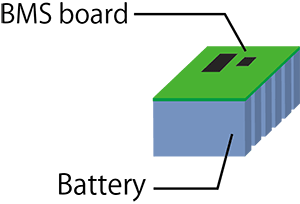

Illustration of an LIB with a BMS board

Illustration of an LIB with a BMS board

DEVELOPMENT BACKGROUND

The transition to electric powertrains for vehicles is accelerating worldwide against the backdrop of resource constraints and environmental problems. Demand for LIB packs is growing along with the EV market, and R&D programs targeting associated technologies are accelerating.

LIB packs incorporate a system board known as a BMS that monitors and optimally controls the battery. Failure of a BMS to properly monitor its battery will lower the product’s efficiency and prevent it from making full use of the battery’s capacity, for example by allowing excessive discharging to degrade the battery or by preventing adequate charging. Control by BMS boards is particularly important because excessive discharge of LIBs poses serious hazards such as fire and electric shock.

Against this backdrop, development of sophisticated BMS boards that can efficiently and safely control batteries is set to increase in the future, and this trend will likely drive up demand for the ability to easily and accurately evaluate those boards.

KEY FEATURES

1. Ability to efficiently build a testing environment by simulating batteries

The ST7081-50 can be used in place of an actual battery, power supply, or electronic load as a simulated battery/voltage generator and simulator.

BMS boards are connected to battery cells, whose capacity and other parameters they monitor. Battery cells exhibit individual differences in capacity due to differences in the operating environment and to manufacturing variations. Differences in capacity prevent adequate charging, making it impossible to take full advantage of the battery. BMS boards address this issue by eliminating variability when individual cells exhibit imbalances in terms of capacity.

Difficulty arises when evaluating the performance of those systems because it is difficult to create the desired state of imbalance with actual batteries. Because it lets the user set or simulate cell conditions as desired using a computer application, the SS7081-50 makes it possible to build a BMS test environment efficiently and easily.

In addition, each SS7081-50 unit offers 12 channels. Multiple units, each capable of simulating 12 cells, can be connected together to create a multi-cell environment. This capability eliminates the cost of preparing numerous power supplies and electronic loads as well as the time that would be required to wire them together and fabricate large systems capable of controlling them.

2. High-precision voltage and current measurement capability and support for measurement of minuscule currents

The SS7081-50 delivers high-precision voltage (±0.01% rdg. ±100 μV) and current (±0.07% rdg. ±100 μA) measurement capabilities to make possible more accurate evaluation of increasingly sophisticated BMS boards.

It also provides a 100 μA (0.1 mA) minuscule current range that is ideal for measuring dark current2 and standby current3. BMS boards draw their power from connected battery cells. It is important to ascertain BMS dark current and standby current in order to limit battery power consumption. The SS7081-50’s minuscule current range can make these measurements with a high degree of precision.

3. Easy and safe simulation of wire breaks

The SS7081-50 can simulate wire breaks in the cable that connects the BMS to its battery. Use of actual batteries to evaluate BMS boards poses difficulties such as the need to fabricate specially designed test rigs and safety issues.

With the SS7081-50, you can easily and safely simulate wire breaks that would be difficult to replicate with an actual battery, making it possible to evaluate the target BMS board’s anomaly detection functionality. The SS7081-50 offers extensive functionality for simulating other defects so that users can evaluate safety from a variety of standpoints.

PRINCIPAL APPLICATIONS

- BMS research and development

- Evaluation of BMS performance during shipping inspection

- 1Lithium-ion battery packs are assembled batteries in which multiple cells are connected together.

- 2Dark current refers to the current consumed while the BMS is powered off.

- 3Standby current refers to the current consumed when the BMS is powered on but not operating.

About HIOKI

Established in 1935, HIOKI E.E. CORPORATION (TSE: 6866) has grown to become a world leader in providing consistent delivery of test and measuring instruments through advanced design, manufacturing, and sales and services. By offering over 200 main products characterized by safety and quality while meeting an expansive range of applications, we aim to contribute to the efficiency and value of our customers' work in research and development, production and electrical maintenance. HIOKI products and services are available around the world through our extensive network of subsidiaries and distributors. Information about HIOKI is available at www.hioki.com.