Components

Contributing to improved reliability and productivity of sophisticated components

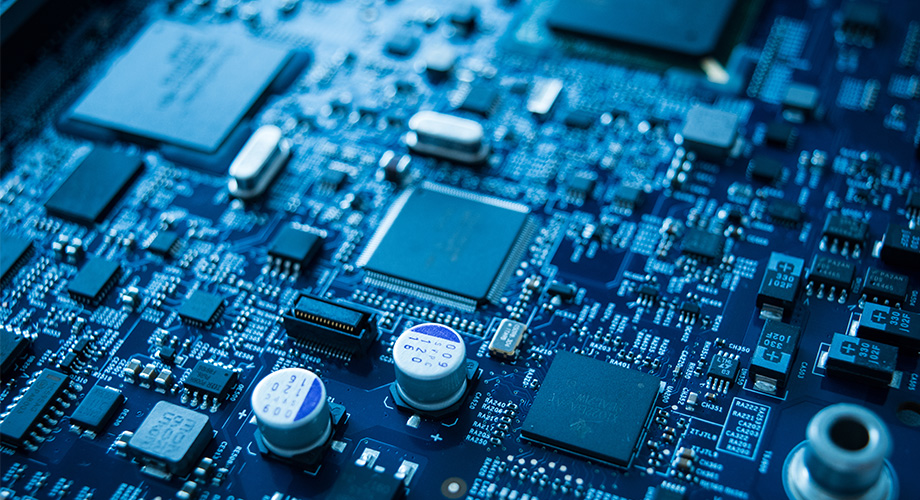

The advancement of smart devices, the spread of electric vehicles and industrial robots, and the drive for greater efficiency in HVAC systems, all demand increasingly sophisticated components in modern electronics. Resistors, capacitors, semiconductors, and motors must meet ever higher standards of reliability and throughput.

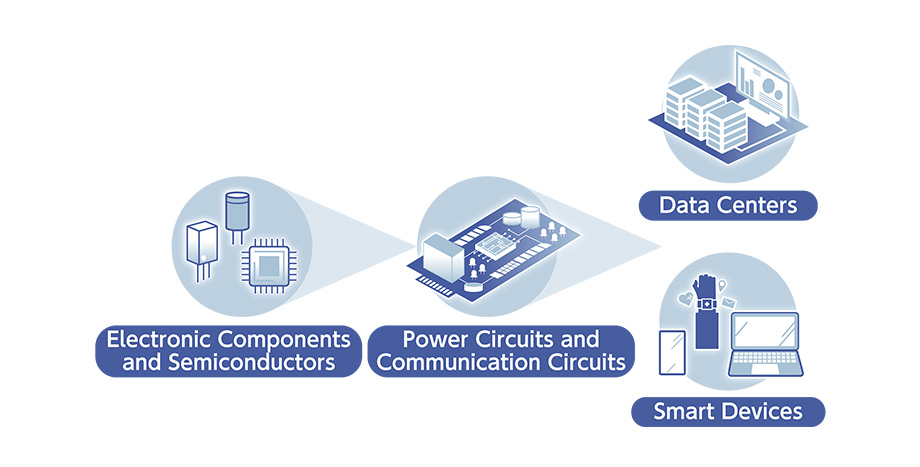

In addition to providing highly precise static measurement technologies for these electronic components and motors, Hioki also supports performance evaluation, quality assurance, and high-speed inspection through board-level testing that includes power and communication circuits where components are mounted. By offering measurement solutions that cover every phase, from development to mass production, Hioki facilitates both the evolution of electronics and the development of sustainable industries.

Measurement solutions that bolster the reliability of electronic components, semiconductors, and circuit boards

Electronic devices such as smart devices, AI systems, and electric vehicles are equipped with high-performance electronic components, semiconductors, and complex circuit boards. From the development stage through to mass production and final assembly, consistent quality assurance and reliability evaluation are essential for these components.

Hioki’s high-precision measurement solutions are ideal for evaluating the performance of resistors, capacitors, and semiconductors, as well as for accurately assessing the electrical characteristics of electronic circuit boards, including power and communication circuits with mounted components. These tools contribute to the development of highly reliable products and stable production.

Main products (electronic component and semiconductor testing)

Main products (circuit board testing)

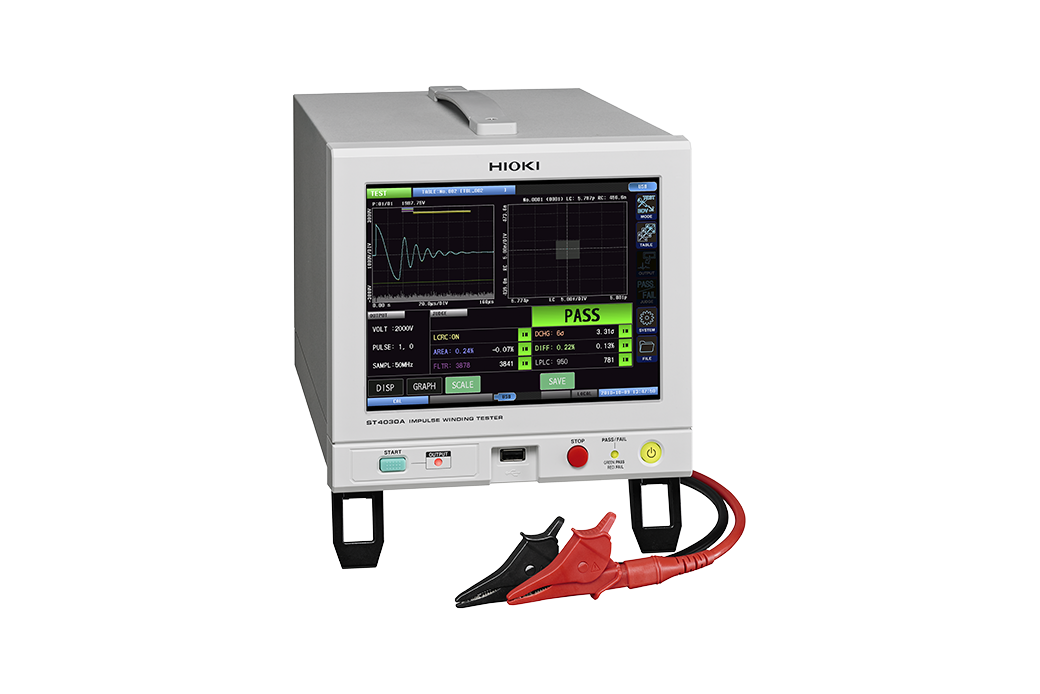

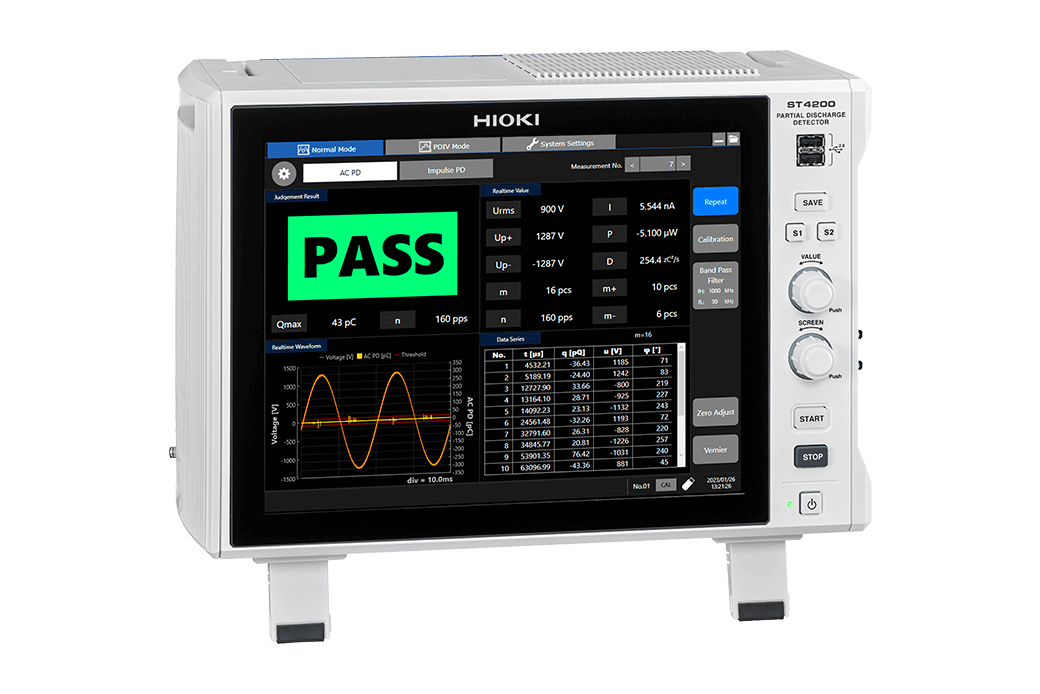

Static inspection solutions that foster motor quality

To ensure that motors used in electric vehicles, HVAC systems, and industrial robots can operate reliably over extended periods of time, it’s essential to assure quality through pre-shipment static inspections.

Hioki provides measurement solutions that accurately evaluate static characteristics such as winding resistance, insulation resistance, inductance, impulse testing (layer short testing), and partial discharge. These solutions help improve both the reliability and productivity of motors.