Product Sep. 01, 2021 HIOKI E.E. CORPORATION

Hioki Announces Power Analyzer PW8001 and AC/DC Current Sensors CT6872 and CT6873

8 Inputs Channels that Provide World Class Flexibility and Accuracy

HIOKI is proud to announce its all new "Power Analyzer PW8001 and AC/DC Current Sensors CT6872 and CT6873." Shipments of both are scheduled to begin at the end of 2021.

The Power Analyzer PW8001 is the new flagship model that brings together Hioki’s full technological expertise of highly advanced analysis and multi-frequency accuracy to respond to modern demands for high-precision, wide frequency bandwidth, and highly stabile measurement. Its next-generation digital platform enables high-speed power analysis of up to an astounding eight channels. In addition, its new current sensor interface makes Hioki’s phase-correction technology, crowning Hioki’s current sensors with unrivaled accuracy in the market, even more reliable and easier to use by automating settings that would otherwise be done by hand.

The CT6872 (50 A current rating) and CT6873 (200 A current rating) are through-type current sensors with dramatically improved frequency bandwidth and noise-resistant performance based on our current market leading current sensors. It is ideal for evaluating compact, high-efficiency power supplies that are increasingly common in the areas of industrial equipment, data centers, and EVs (electric vehicles). Their performance are truly pronounced in the evaluation of high-speed switching power supplies equipped with next-generation power semiconductors composed of SiC (silicon carbide) and GaN (gallium nitride)*1.

Takahiro Okazawa, Hioki’s President, says:

"We at HIOKI are determined to contribute to the safe and efficient use of energy by our customers through electric measurement, and to contribute to the peace of mind and development of society. Through new measurement solutions based on the Power Analyzer PW8001 and AC/DC Current Sensors CT6872 and CT6873, we will contribute to the realization of a sustainable society together with our customers worldwide."

Development Background

In order to prevent global warming and ensure our next generation can flourish in earth’s precious natural environment, efforts are being made around the world to realize a carbon-free society. One of these efforts is the electrification of automobiles. Fervent research and development in electrification and performance improvement is accelerating on a global scale. Efficiency and miniaturization of motors and power supplies which is key in this research, is furthering demands for sophisticated measurement of materials, parts, and electric control. Measurement instruments now require more precise and stable measurements of DC (0 Hz frequency) to high frequency currents, large currents, and low power factor. At the same time, devices being measured are increasingly complex and require multiple channels.

Meanwhile, when we look at energy generation, development related in renewable energy such as wind power and solar power is also accelerating worldwide. In order to make these renewable energies worthwhile, greater energy efficiency and lower costs for generation become important. For this, the development of related equipment to be higher voltage, lower cost, and higher productivity is on the rise. In this environment, measuring instruments are required to measure high voltages and multiples channels with high accuracy while being low cost.

We have developed the Power Analyzer PW8001 and Current Sensors CT6872 and CT6873 to meet the growing demands for measurement in these backgrounds.

Features of the PW8001

1. Custom Power Analyzer through 2-tiered Modules: World Class Accuracy, Wideband Power Measurement, and High Voltage Measurement

In order to attain world class accuracy, accuracy of DC (direct current) of 0 Hz frequency, commercial power accuracy (wall outlet) of 50/60 Hz frequencies and accuracy of higher frequencies must all be high. This is because most devices run on many frequencies. However, most power measurement devices focus on accuracy of either DC or the commercial frequencies (50/60 Hz). The PW8001 (module U7005*2) however achieves world class basic power accuracy of ±0.03% for commercial (50/60 Hz), and a DC (0 Hz) power accuracy of ±0.05% to provide more accuracy than other standard power analyzers in the market. In addition, this flagship model offers greater accuracy than competitors in measuring high-frequency power. The 5 MHz measurement bandwidth (increased from the previous model’s 2 MHz) is more important for SiC and GaN, the next-generation semiconductors increasing in use worldwide. The high accuracy in this overall wide frequency range makes it possible for users to accurately evaluate power conversion efficiency (or loss) of even more than 99% for power electronics equipment. In today’s technology where equipment are becoming more efficient and high-frequency, Hioki-level accuracy is essential to further improve performance.

Furthermore, this power analyzer gives the choice of two input modules with different measurement accuracy and measurement frequency bandwidth specs. Up to 8 input modules of the user’s choice (U7005 or U7001) can be freely combined into a single PW8001. The high-end module, U7005 (with aforementioned accuracy specs) and the more affordable module U7001 (basic power accuracy of ±0.07% and DC power accuracy of ±0.07% for commercial frequencies) allow for the optimum measuring system best suited for the user’s situation. Although the U7001 is marketed as the “affordable model,” its accuracy is nearly equivalent to that of the market-leading predecessor.

In addition, the new “affordable model” (U7001) allows for high voltage measurement of DC power. Rated at “DC 1500 V Category II” (CAT II), it can safely and accurately evaluate power supply equipment with a 1500 V DC voltage.

2. High Flexibility from a Revolutionary 8 channels and a Wide Array of Functions

The Power Analyzer allows the user to further tailor the analyzer to his/her specific application through its revolutionary number of 8 channels and many optional functions.

By providing a revolutionary number of 8 channels, Hioki’s single Power Analyzer can measure power efficiency of 2 independent 3-phase inverters, by comparing the power of each inverter’s single DC line and 3 AC lines. Comparable competitors only provide up to 7 channels, making this impossible without Hioki.

In addition to the standard 8 of 2-tiered modules, we have also prepared a function that can analyze four motors with just one Power Analyzer PW8001 by simultaneously measuring four sets of torque and rotation speed. This is very useful for evaluating complex systems such as in-wheel motors or electric AWD (all-wheel drive) systems installed in EVs in which individual wheels are controlled by several motors. (This Motor Analysis input is an optional function that must be specified when ordering.)

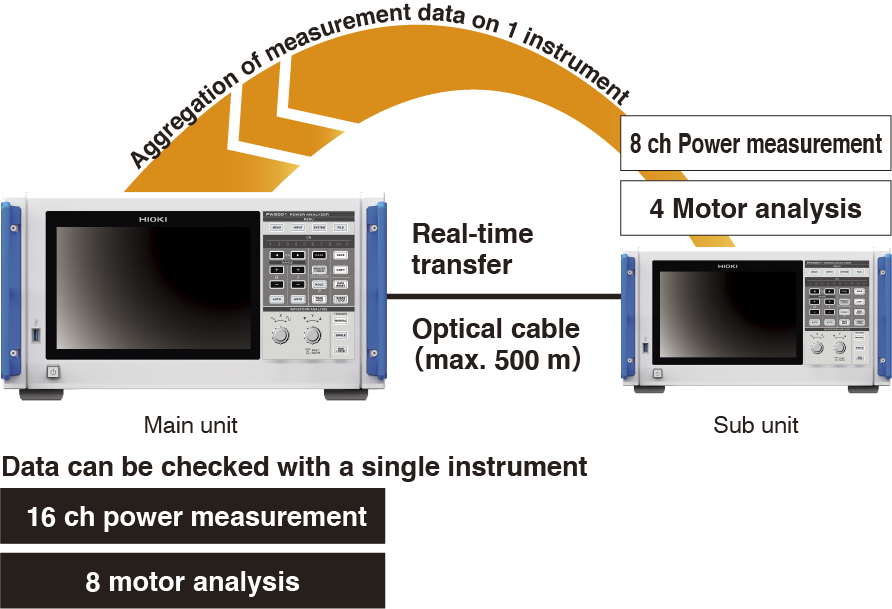

Another function that adds flexibility is the Optical Link Interface*2 function. In order to respond to the increasing scale and complexity of power measurement, we have made it possible to measure up to 16 channels by connecting two PW8001s with optical cables. By combining two units, measured data is aggregated into one of the PW8001s in real time. This enables display, analysis, and recording for all 16 channels to be done on one device. (The Optical Link Interface*2, is an optional function that must be specified when ordering.)

Image of Optical Link Interface Function

Image of Optical Link Interface Function

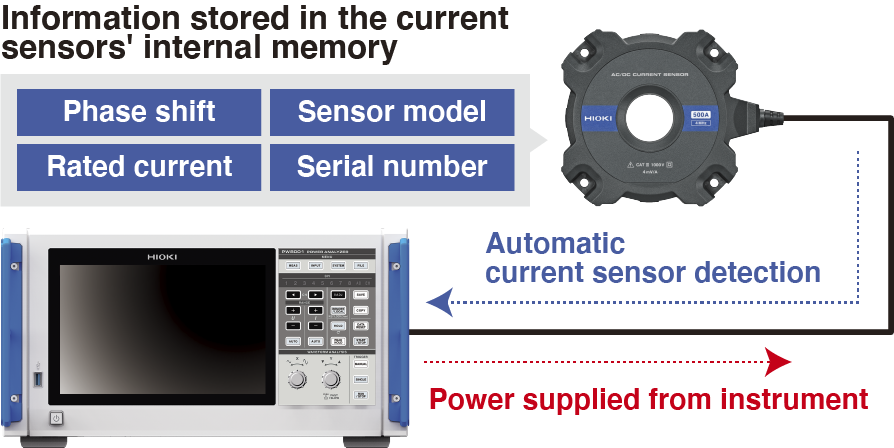

3. High Accuracy Made Easy with the New Current Sensor Interface

High frequency power measurements are notorious for poor accuracy due to the higher alternating frequency of the electricity which causes current sensor’s accuracy to decline. However, Hioki’s unparalleled Phase Shift function can use Hioki’s fine-tuned current sensors to offset this phenomena. This is made possible only because Hioki makes both its power analyzers and sensors in-house, giving Hioki a unique place in the market. This function makes efficiency measurement of inverters and loss measurement of high frequency reactors and transformers perfect for Hioki’s Power Analyzer. Until now, Hioki sensors simply required input of the sensor model’s phase error digits. The new current sensor interface in the Power Analyzer PW8001 and new sensors now make Phase Shifting incredibly easy. The Analyzer simply adjusting everything automatically as soon as the sensor is plugged in. This maximizes the performance of the current sensor without the need for tedious settings when preparing for measurement.

Image of New Current Sensor Interface

Image of New Current Sensor Interface

4. Streamline Automotive Development by Outputting Measurement Data as a CAN/CAN-FD Automotive Control Signal

In systems used in developing vehicles, the in-vehicle communication protocol of CAN or CAN-FD is widely used to aggregate data. Until now, CAN/CAN-FD signals and power analyzers’ analog output signals were collected simultaneously, then later all data were integrated into a data logger. However, analog output signals pose problems such as repeatability degradation at the time of integration and limited number of outputs. To solve these problems, the PW8001 offers an optional function that outputs the measured power data as a CAN signal. This allows data to integrate many channels without degradation of power measurement accuracy for simultaneous evaluation of many behaviors of a vehicle. (This CAN/CAN-FD Interface*2 is an optional function that must specified when ordering.)

Features of the Sensors CT6872 and CT6873

1. Next-Generation Semiconductors Power Evaluation

Next-generation semiconductor power inverters, such as SiCs and GaNs, often convert power into extremely high frequencies, too high for accurate measurement by non-Hioki sensors. The Hioki Current Sensors CT6872 and CT6873 are able to measure these frequencies very accurately with frequency bandwidths of up to 10 MHz and 5 MHz, respectively (a surprising 10-times increase from their previous models). In addition, these sensors are more accurate than their predecessor models with market leading accuracy by improving their amplitude/current accuracy and noise resistance (Common Mode Noise Rejection Ratio). These Hioki Current Sensors with such dramatically advanced performance, combined with the Power Analyzer PW8001’s excellent high-frequency accuracy, enables accurate and highly reproducible power supply evaluations even in the high-speed switching power supplies equipped with next-generation semiconductors such as SiCs and GaNs.

AC/DC Current Sensors CT6872 and CT6873

AC/DC Current Sensors CT6872 and CT6873

Main Applications/Customers

- Evaluation of power conversion efficiency and loss in research & development and production processes

- Manufacturers of EVs, FCVs (fuel cell vehicles), other automobiles, and their chargers

- Manufacturers of equipment for renewable energy generation such as wind and solar

Dedicated website for these products

(English) https://www.hioki.com/global/products/power-meters/power-analyzer/id_412384

(Japanese) https://www.hioki.co.jp/jp/products/detail/?product_key=1907

- *1SiC and GaN are new, low-loss, high-voltage, power semiconductors suitable for high-temperature operation. Their use in high-performance power supply equipment is expanding because these semiconductors’ characteristics allow for smaller passive electronic components and cooling devices.

- *2Scheduled to be released in 2022.

- *3Company and product names used in this release are the trademarks or registered trademarks of their respective owners.

About HIOKI

Established in 1935, HIOKI E.E. CORPORATION (TSE: 6866) has grown to become a world leader in providing consistent delivery of test and measuring instruments through advanced design, manufacturing, and sales and services. By offering over 200 main products characterized by safety and quality while meeting an expansive range of applications, we aim to contribute to the efficiency and value of our customers' work in research and development, production and electrical maintenance. Hioki products and services are available around the world through our extensive network of subsidiaries and distributors. For more information, visit us at www.hioki.com.