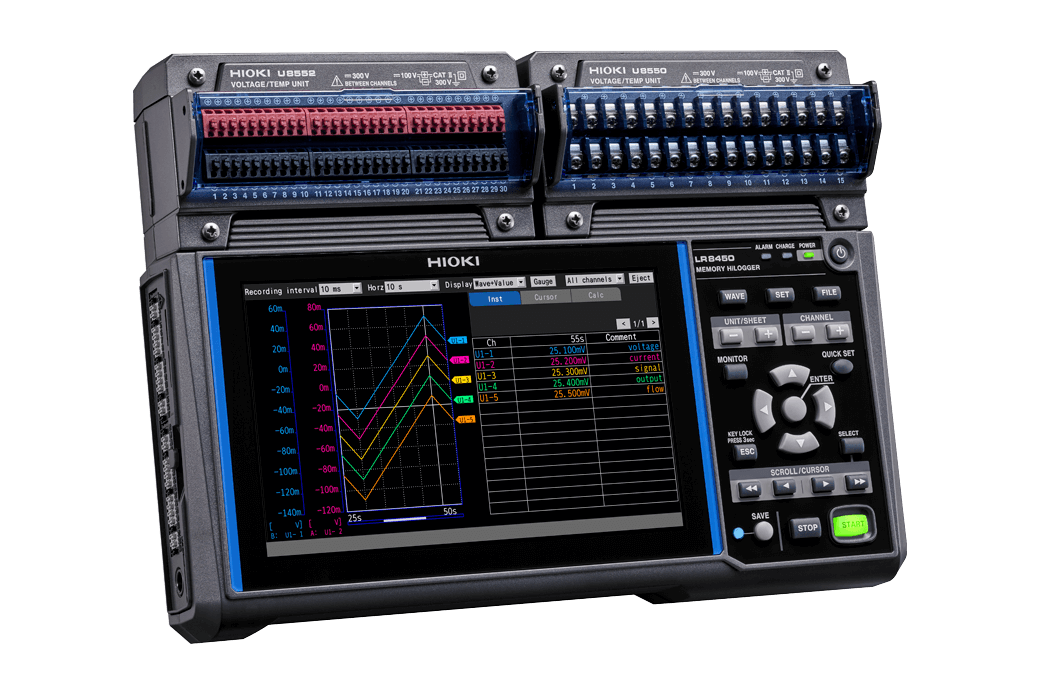

MEMORY HiLOGGER LR8450

1 ms Sampling Portable Logger Expandable to 120 Channels with Your Choice of Plug-in Modules

Hioki Memory HiLoggers are high-speed data loggers for recording multiple channels of voltage, temperature, resistance or humidity signals, some models providing complete isolation between channels and strong noise resistance.

The LR8450 offers a sampling speed of up to 1 ms and up to 120 channels, depending on the types of plug-in modules that are selected. The modules measure strain and distortion, ideal for automotive applications involving the evaluation of vehicle components as well as robotic equipment.

Actual measurement example using CAN UNIT

This video shows how the MEMORY HiLOGGER LR8450-01 and CAN UNIT are used to measure the temperature of an actual vehicle. The analog data measuring the temperature inside the vehicle and the CAN data are simultaneously displayed on the waveform in real time. You can also see how the measured analog data is output as CAN signals in real time.

Stable Logging - Even at High Voltages and Frequencies. Minimize the Effects of Noise.

The LR8450 reduces the effects of noise to deliver stable logging, even at high voltages and frequencies.

Legacy data loggers could not log temperature accurately in noisy environments due to the effects of high frequencies, which caused values to shift or fluctuate significantly.

Hioki Memory HiLogger LR8450 uses a revamped design to dramatically reduce the effects of high-frequency noise, and is ideal for temperature logging of inverters and batteries.

Key Features

- Expandable to 120 ch with wired/plug-in modules

- Record voltage output from pressure and other sensors with 1ms sampling speed

- Directly connect strain gauge and measure signals in as fast as 1ms intervals

- Significantly reduced effects from noise let you safely measure in high voltage and high frequency areas such as around inverter motors

Model No. (Order Code)

| LR8450 Data Logger kit | LR8450 w/ C1012, Z4003, 2 x Z1007 |

|---|

Scope 3 emission reduction through recording of current consumption and heat energy loss

To attain Scope 3 (*1) emissions targets and ensure alignment with decarbonization goals, it is important to accurately understand the impact of our products on the environment.

We will offer tips to aid developers striving for Scope 3 compliance, focusing on techniques to pinpoint energy losses in electronic components through current and temperature data acquisition.

Measurement of Leakage Current in EV Power Management

In the domain of e-mobility, especially electric vehicles (EV), range extension is one of the most important priorities. To boost range, it’s important to measure power consumption and leakage current not only for batteries and powertrains, which use a large amount of power, but also for devices such as ECUs and electrical accessories.

Connect strain gages directly and make measurements in as little as 1 ms.

The Memory HiLogger LR8450 is a data logger that can measure stress via directly connected strain gages. Capable of recording at frequencies on the order of dozens of hertz thanks to sampling at up to 1 ms, the LR8450 is ideal for measuring stress and load on moving parts and strain on components such as brakes and pipes. And because it can accommodate a mix of various measurement units, the LR8450 can simultaneously measure strain, temperature, and voltage as necessary.

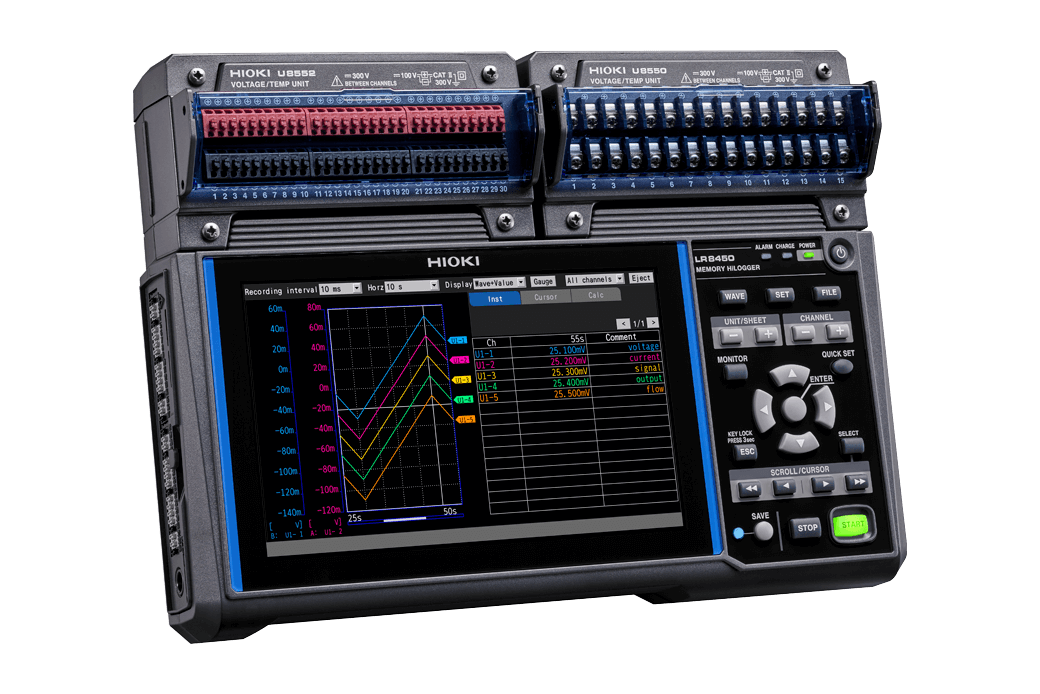

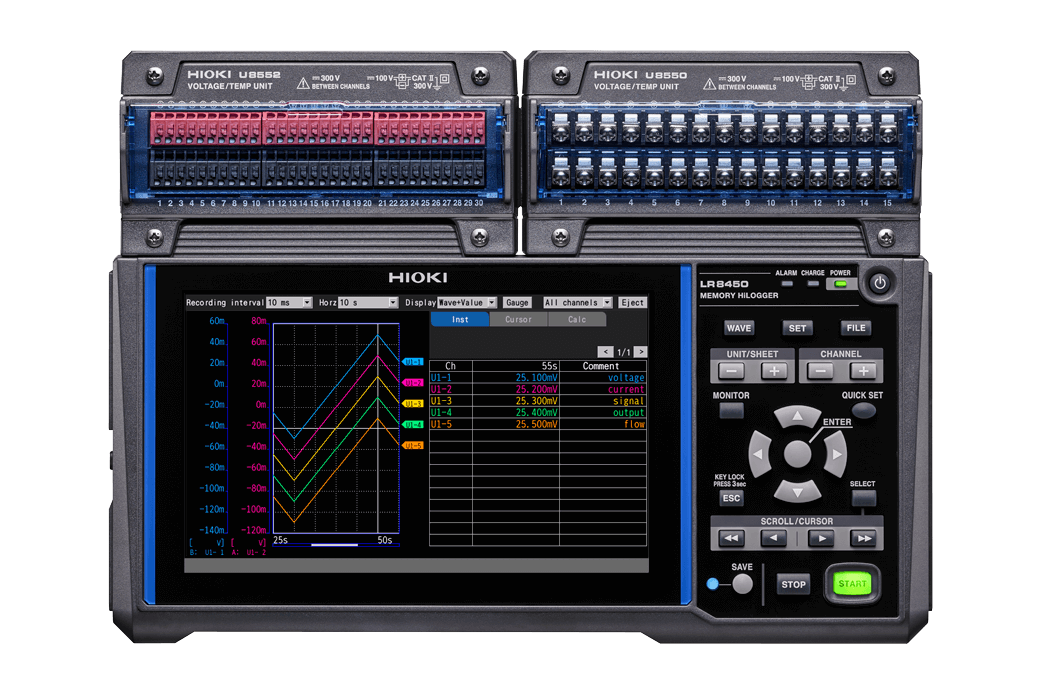

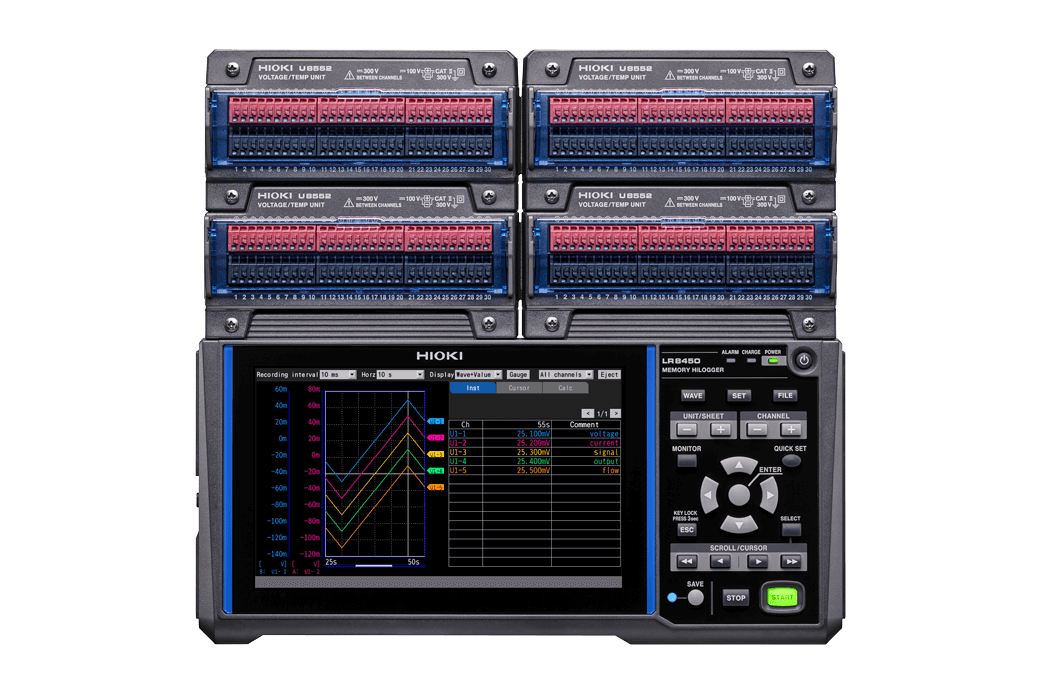

Gain up to 120 channels of input simply by adding a total of four plug-in modules

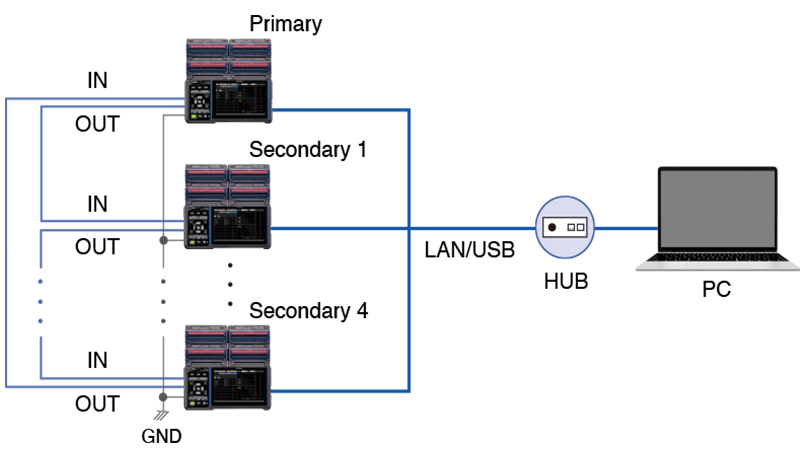

Analog 600 CH Synchronous Sampling Measurement [Since V2.10]

Synchronized sampling up to 5 plug-in modules (600 analog channels) can be measured when multiple LR8450's external sync terminals (SYNC.IN, SYNC.OUT) are connected.

Note: This function cannot be used when wireless modules are connected.

Sample output from a variety of sensors, including 1 ms pressure sensors

Use model High Speed Voltage Unit U8553

Measures at a sampling rate of up to 1 ms.

1 ms sampling rate is the best match to measure sensor outputs with a frequency response of under 100 Hz, for example pressure and vibration sensors.

Measure strain with a 1 ms sampling rate

Example: strain measurement

Use model Strain Unit U8554

Connect strain gauges directly and measure at a sampling rate of up to 1 ms.

Strain gauges tend to have long, thin wires that are easily broken, but that potential pitfall can be avoided by using wireless modules so that wire length is minimized.

Measure temperature near an inverter or battery

Example: temperature measurement

Use models:

Voltage/Temp Unit U8550

Universal Unit U8551

Measures at a sampling rate of up to 10 ms.

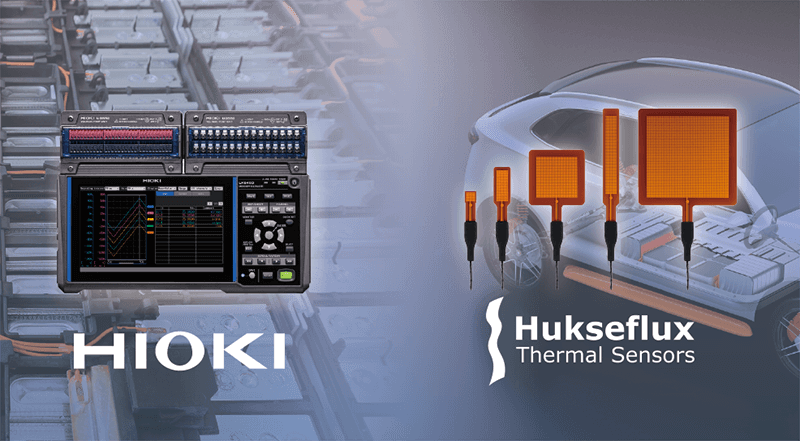

Battery EV thermal management by measuring temperature and heat flow

Heat flow can be measured by combining the LR8450 with the FHF05 Heat Flux Sensor. Since these sensors allow both temperature and the direction of heat movement to be confirmed, they are useful when validating thermal management.

Dedicated cloud service for Hioki's GENNECT series

You can access remote instruments anytime, anywhere

GENNECT Cloud

"GENNECT Cloud" is a remote measurement service that anyone can easily start.

By connecting to the Internet, you can easily check the latest measurement values, send alarms, collect measurement files, and perform remote control.

GENNECT One

"GENNECT One" is a free Windows application that provides central management of multiple instruments on a LAN. By logging in to GENNECT Cloud from GENNECT One, you can move beyond your LAN and connect to instruments in remote locations.

Basic specifications

| Max. number of connectable modules | 4 plug-in modules | |||||

|---|---|---|---|---|---|---|

| Connectable modules (Plug-in modules) |

See [Options] > [Plug-in modules] | |||||

| No. of measurement channels | Up to 120 ch with plug-in modules. U8555 can input up to 500 channels per unit. |

|||||

| Pulse/logic input | [Number of ch] 8 ch (common GND, non-isolated, exclusive setting for pulse/logic input for individual channels) [Adaptive input format] Non-voltage contact, open collector, or voltage input [Count] 0 to 1000 M pulse, 1 pulse resolution [Rotational speed] 0 to 5000/n (r/s), 1/n (r/s) resolution, 0 to 300,000/n (r/min.), 1/n (r/min.) resolution, n: Number of pulses per rotation (1 to 1000) [Logic input] Records 1 or 0 for each recording interval |

|||||

| Recording intervals | 1 ms*, 2 ms*, 5 ms* (*: Can be set only when using 1 ms/S modules), 10 ms to 1 hour, 22 selections (Data refresh interval can be set for each unit | |||||

| Data storage | SD Memory Card/USB Drive (user-selectable) (Only storage media sold by HIOKI are guaranteed for operation) |

|||||

| LAN interface | 100BASE-TX / 1000BASE-T, DHCP, DNS support, Functions: Data acquisition, condition settings used with the Logger Utility software, configuring settings and controlling recording using communications commands, FTP server / FTP client, HTTP server, Email transmission, NTP client |

|||||

| USB interface | Series A receptacle × 2: USB 2.0 compliant (USB drive, keyboard, or hub) Series mini-B receptacle × 1: Data acquisition, condition settings used with the Logger Utility, configuring settings and controlling recording using communications commands, transferring data from a connected SD Memory Card to a computer |

|||||

| SD card slot | SD standard-compliant slot × 1 (with SD memory card/SDHC memory card support), Guaranteed-operation options: Z4001, Z4003 | |||||

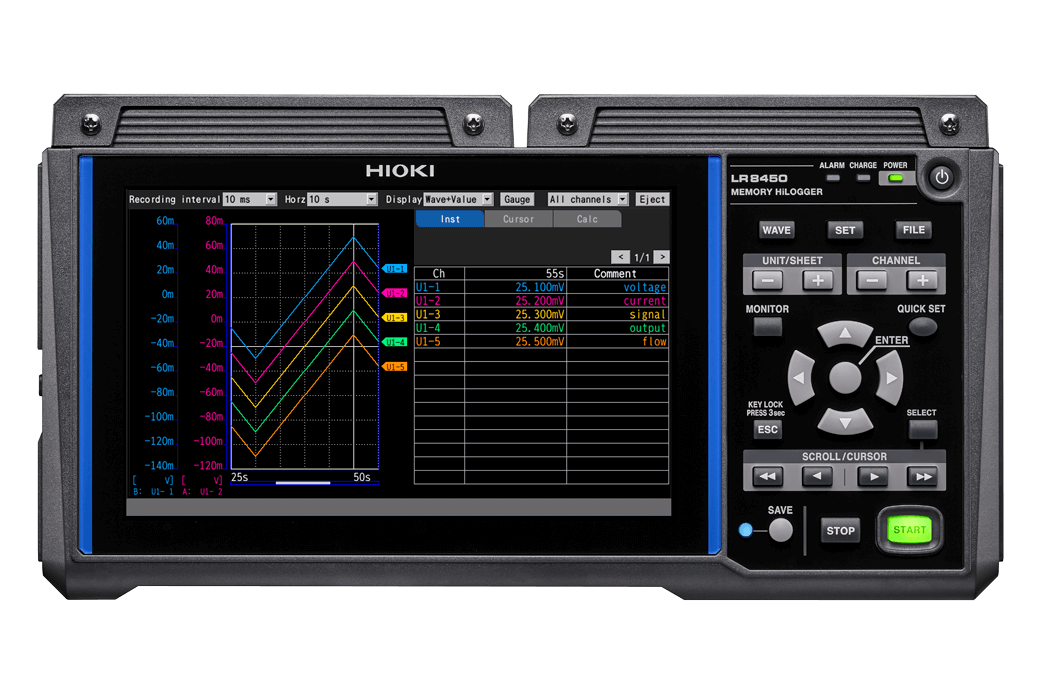

| Display | 7 inch TFT color liquid crystal display (WVGA 800 × 480 pixel) | |||||

| Functions | Save waveform data in real time to the SD memory card or USB drive, numerical value calculations, waveform calculations, 8ch alarm output, voltage output ×2 (5 V /12 V /24 V selectable) | |||||

| Power supply | [AC adapter] Using the Z1014 (100 to 240 V AC, 50/60 Hz), 95 VA Max. (including AC adapter), 28 VA Max. (exclusive of AC adapter) [Battery Pack] Using the Z1007 (accommodates 2 batteries), continuous use 4 hr (reference value for 2 pieces), 20 VA Max. [External power] 10 to 30 V DC, 28 VA Max. |

|||||

| Dimensions and mass | Without any modules: 272 mm (10.71 in) W × 145 mm (5.71 in) H × 43 mm (1.69 in) D (excluding protrusions), 1108 g (39.1 oz) (excluding battery pack) With 2 modules: 272 mm (10.71 in) W × 198 mm (7.80 in) H × 63 mm (2.48 in) D (excluding protrusions) With 4 modules: 272 mm (10.71 in) W × 252 mm (9.92 in) H × 63 mm (2.48 in) D (excluding protrusions) |

|||||

| Included accessories | Quick Start Manual ×1, USB Cable ×1, AC Adapter Z1014 ×1 | |||||

Plug-in Modules (7)

Input options, current sensors (3)

- Note: The current module U8556 is necessary to connect the current sensors. For other compatible current sensors, please refer to the options listed in module U8556.

- Thermocouple: for reference only. Please purchase locally.

(Analog output), 3 m (9.84 ft) length

Storage media (3)

Precaution on purchasing memory device

Use only the memory device sold by HIOKI. Compatibility and performance are not guaranteed for memory device made by other manufacturers. You may be unable to read from or save data to such devices.

2 GB capacity

8 GB capacity

16 GB, long-life, high-reliability SLC flash memory

Power supply (3)

*AC adapter is bundled with the LR8450, LR8450-01

For main unit, DC drive, Connect to external battery, Unprocessed ends, Approx. 2 m (6.6 ft.)

Li-ion, charges while installed

100 to 240 V AC

Carrying cases / stands (2)

Includes space for options

For installing logger on wall

PC peripherals (4)

LOGGER UTILITY is a bundled software, Real-time data collection will be supported by version upgrade

Straight Ethernet cable, supplied with straight-to-cross conversion adapter, 5 m (16.4 ft.)

- Durability Assessment of Motors Based on Temperature and Power Data in Endurance Testing

- Streamlining Motor Development by Integrating High-Speed Waveforms and Multi-Point Temps

- Minimizing PCB Processing Stress for Improved Reliability

- Optimizing Switching Power Supply Selection Through Precise Current Measurement

- AEC-Q200-compliant evaluation of the temperature of electronic components

- Accelerate product development for Scope 3 emission reduction

- Measurement of Leakage Current in EV Power Management

- Test the Temperature Distribution of a Motor

- Battery EV Thermal Management

- ISO 21782: EV Propulsion Component Test Specifications and Measuring Instruments

- The Role of Separators in Lithium-ion Batteries and Shutdown Testing