Streamlining Motor Development by Integrating High-Speed Waveforms and Multi-Point Temps

Introduction

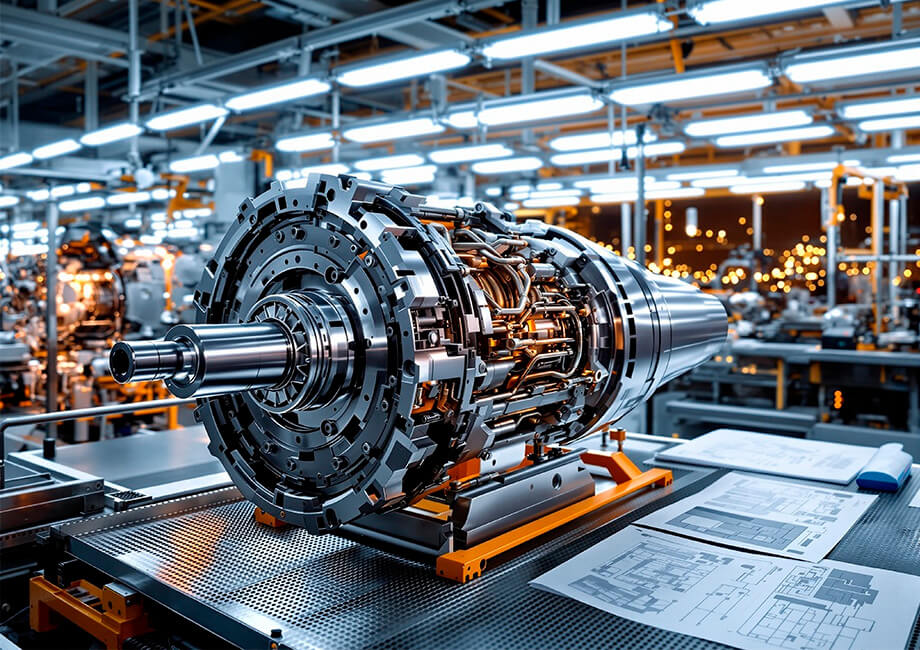

In the development of electric powertrains, achieving high efficiency while ensuring reliability presents significant challenges. Motors and inverters are becoming smaller and more powerful, leading to increased heat density that can compromise performance and longevity. At the same time, overdesigning cooling systems to mitigate this heat can inflate power consumption, undermining the overall energy efficiency of the system. Engineers must precisely understand how electrical losses translate into thermal effects to optimize designs without unnecessary trade-offs.

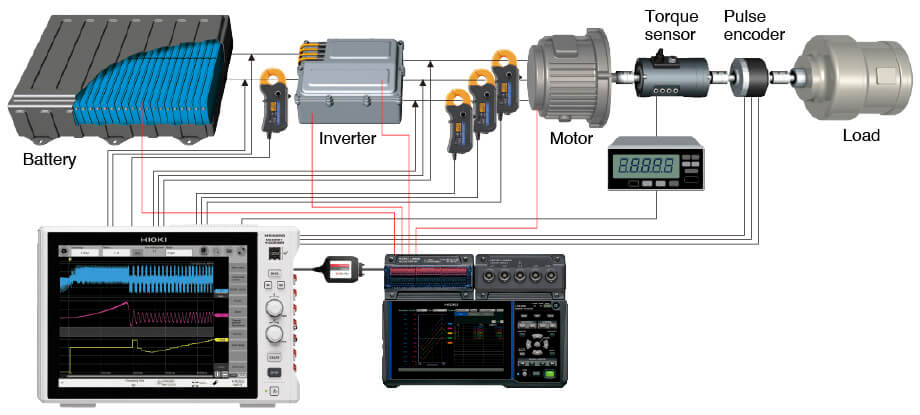

Hioki offers a practical solution through simultaneous measurement of high-speed waveforms and multi-point temperatures, enabling clear insights into motor thermal behavior. The Memory HiCorder MR6000, combined with the Memory HiLogger LR8450, addresses these motor inverter verification challenges by allowing researchers to evaluate waveform and temperature rise recordings efficiently. This approach empowers R&D teams to detect anomalies quickly, reduce development time, and enhance system reliability—ultimately safeguarding operational continuity for power conversion applications.

Trade-offs in Motor Heat Generation and Cooling Design

As motors are miniaturized, winding resistance rises, amplifying Joule heat losses (I²R losses) and concentrating heat within the device. High-speed rotation to maintain output further escalates switching and iron losses, exacerbating internal thermal buildup. Excessive cooling to counteract this—via pumps or fans—can diminish vehicle-wide power performance, creating a delicate balance for designers.

To navigate this, accurate quantification of heat distribution through real-device testing is essential, complemented by simulation validation. By integrating fast waveform phenomena with numerous temperature records, engineers gain a comprehensive view, streamlining the identification of heat sources and improving design precision.

The Value of Simultaneous Waveform and Temperature Measurement

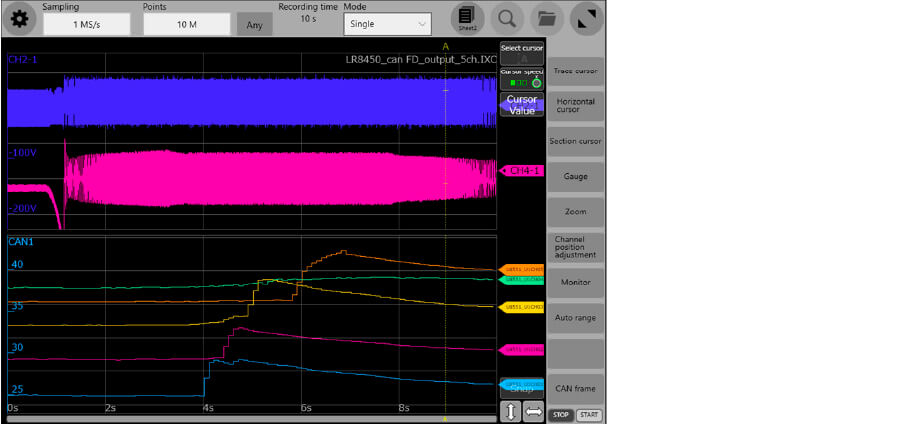

In motors and inverters, losses occur instantaneously with current flow, accumulating as heat over time. While voltage and current waveforms estimate loss trends, they fail to reveal when, where, or how much temperature rises result. Temperature data alone cannot link rises to specific events like switching, energization, or load changes.

Synchronizing these on a single timeline unlocks key insights, such as the propagation of winding Joule losses to the stator or housing, or the response speed of end rings and heat sinks. This highlights the temporal delay in converting electrical stress to heat, a critical factor often demanding intensive simulations. The Hioki Memory HiCorder MR6000 excels here with high-speed waveform recording and isolated channel inputs for increased safety, while the Memory HiLogger LR8450 handles up to 90 temperature channels, delivering efficiency gains by simplifying multi-point analysis and reducing diagnostic risks.

Effective Temperature Measurement Points

For optimal results, focus on these strategic locations:

- Near semiconductor elements or power device causing them to capture switching loss impacts.

- On motor windings, stator surfaces, and housing exteriors to assess Joule losses from energization and verify heat dissipation.

- At cooling system components, like heat sink inlets/outlets, to evaluate design adequacy.

Recording across these points simultaneously pinpoints heat generation and stagnation, enabling targeted improvements.

| Configuration Example | Description | Benefits |

|---|---|---|

| Memory HiCorder MR6000 | High-speed sampling up to 200 MS/s, 16 channels | Ensures precise capture of transient waveforms, enhancing anomaly detection efficiency. |

| Memory HiLogger LR8450 | Up to 90 channels for temperature, CAN integration | Facilitates multi-point logging, reducing setup time and improving data integration for R&D workflows. |

| Combined Setup | CAN-linked data synchronization | Streamlines analysis, minimizing errors and accelerating development cycles. |

Leveraging Measurement Data for Design Feedback

Overlaying waveform and temperature data enables advanced analysis:

- Visualize what causes switching loss in order to refine drive conditions.

- Quantify correlations between winding current ripples and temperature rises for better structure or control logic.

- Assess cooling response delays to reevaluate heat sink or flow path designs.

These insights directly inform parameter optimizations, fostering efficient, reliable power devices. With Hioki’s Memory HiCorder MR6000 and Memory HiLogger LR8450, data integration eliminates post-measurement merging, ensuring accurate, reproducible thermal analysis.

Fig. 1 Measurement points illustration.

Fig. 2 Waveform recording example.

Hioki's Integrated Solution

Combining the Hioki Memory HiCorder MR6000 for insulated, high-potential waveform capture with the Memory HiLogger LR8450 for extensive temperature collection via CAN transmission achieves seamless data synchronization. This setup bypasses manual alignment, promoting precision and ease in heat mechanism studies.

Summary

Simultaneous waveform and temperature measurement visualizes heat source timelines, quantifies electrical-thermal relationships, and guides cooling and loss optimizations. Hioki’s Memory HiCorder MR6000 and Memory HiLogger LR8450 fulfill engineers' needs for viewing electricity and heat together, supporting efficient motor designs in R&D. Explore the MR6000 and LR8450 at Hioki's product page on Web site for detailed configurations and to enhance your power conversion projects.

For detailed setup procedures and examples of CAN communication settings, please refer to the User's Guide.

Simultaneous Recording of High-Speed Waveforms and Multi-Point Temperature Data Using MR6000 and LR8450

For a demonstration or consultation on a specific application, please contact us.