The Role of Separators in Lithium-ion Batteries and Shutdown Testing

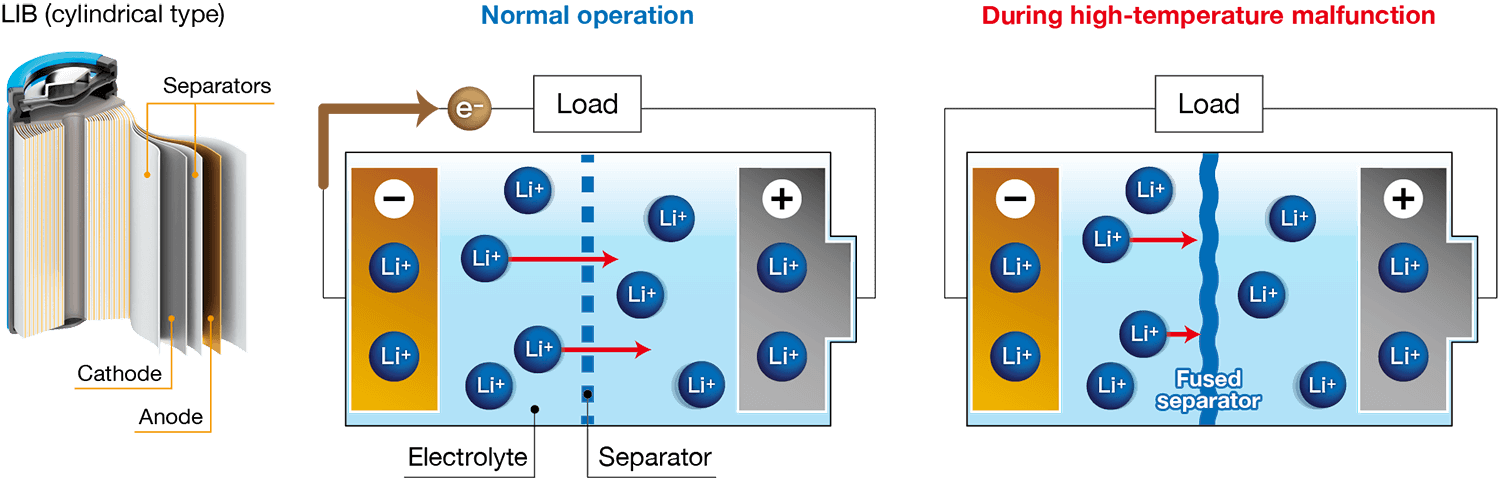

Lithium-ion batteries (LIBs) are widely used in many areas of daily life, for example in electric vehicles, household appliances, and power tools. LIBs, which are required to deliver a high level of reliability, consist of positive and negative electrodes, separators, electrolyte, collectors, and an enclosure. The positive and negative electrodes are insulated by separators. Separators maintain electrical insulation while allowing lithium ions to pass through them, and the entire assembly operates as a battery as ions move through the electrolyte. If an LIB becomes hot due to a malfunction, the separators will fuse and block the movement of ions. This function, known as “shutdown,” stops the battery from operating, and preventing a hazardous state. The shutting down testing, which increases the temperature and verifies that the separators’ characteristics change in response, plays an essential role for improving LIB reliability.

LIB mechanism and separator role

The properties of separators allow lithium ions to pass through them while maintaining electrical insulation. The entire assembly operates as a battery when lithium ions move through the electrolyte.

Shutdown function of separators

When a battery enters a high-temperature state, its separators will fuse, closing off the holes in them and blocking the movement of lithium ions. As a result, the battery will stop operating to prevent a hazardous state.

Issues

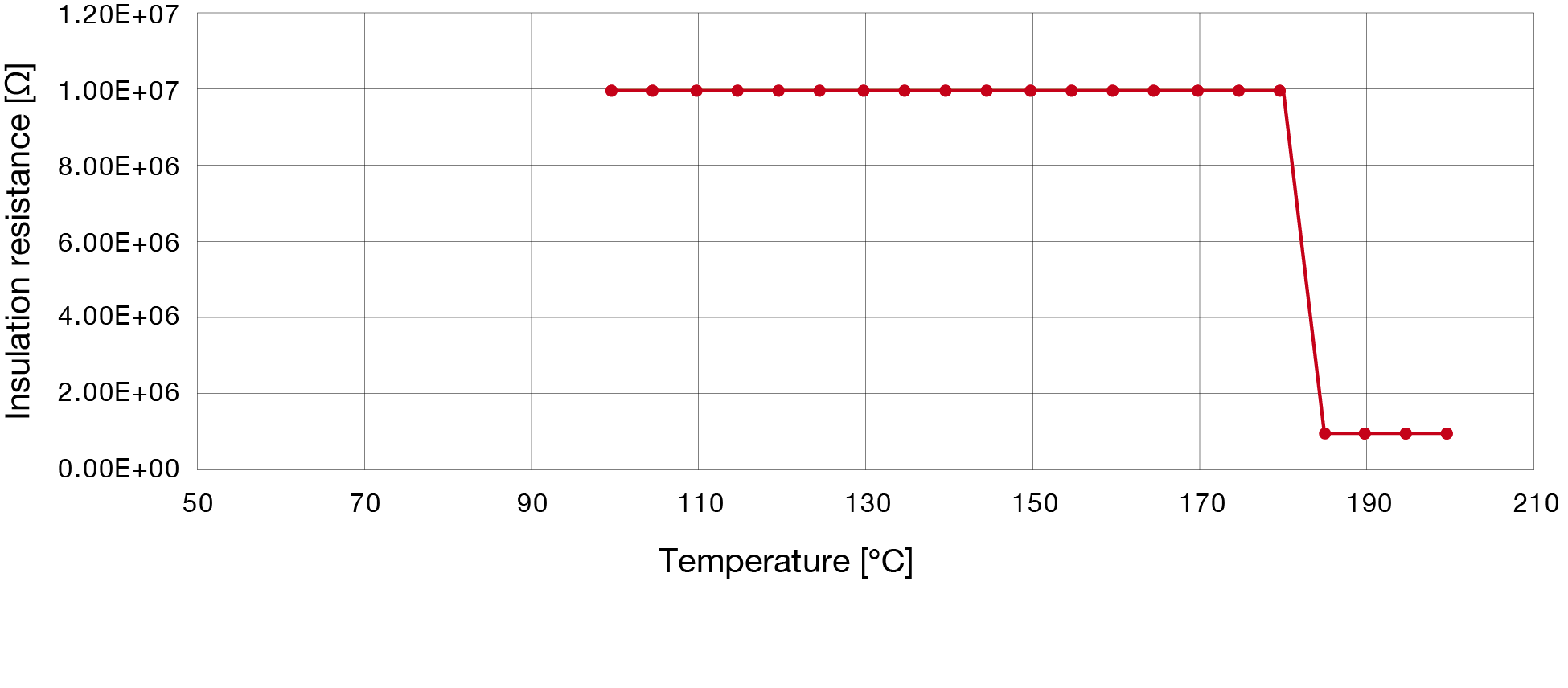

It’s necessary to verify how separator characteristics change as the temperature changes. Those characteristics can be evaluated as the electrical characteristics of impedance (AC resistance) and insulation resistance. One effective method is to plot the characteristic being evaluated on the vertical axis of a graph versus temperature on the horizontal axis. It’s typical to create such graphs with spreadsheet software for use as evaluation reports.

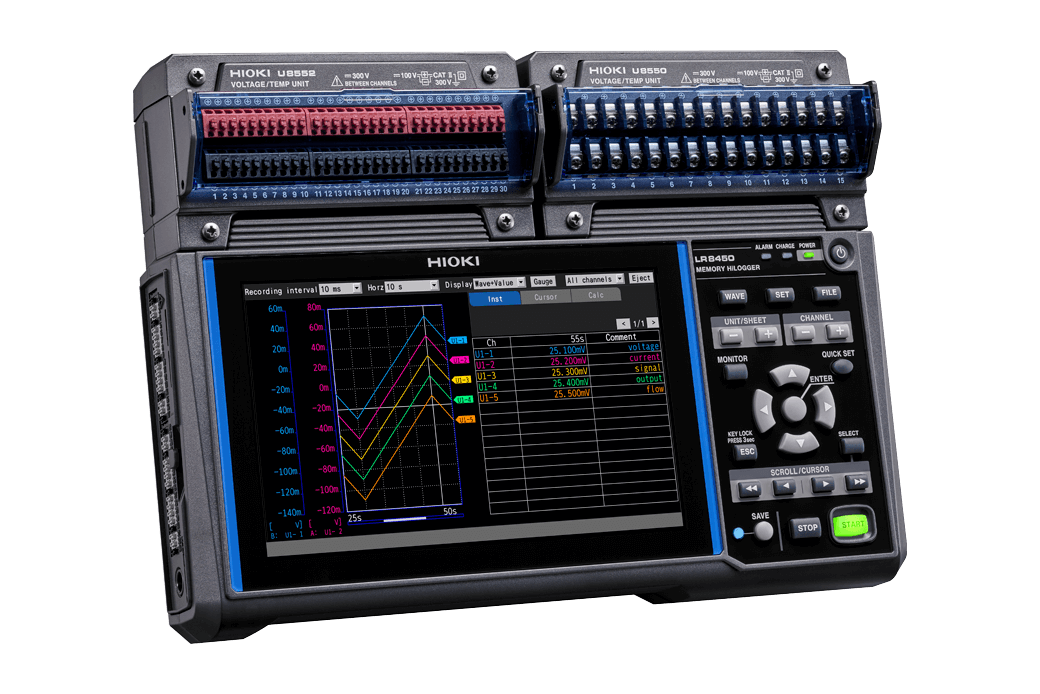

However, the instrument that measures the separators’ electrical characteristics and the instrument that monitors the changes in temperature for a long period of time are often different instruments, causing time-consuming to integrate the data from each instrument.

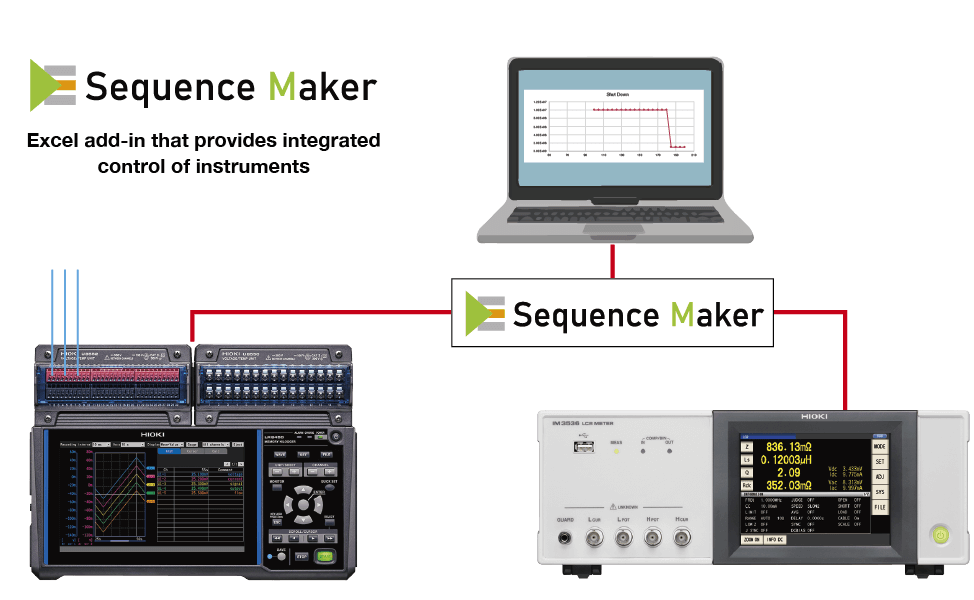

Solution

“Sequence Maker” is an Excel add-in that provides integrated control of measuring instruments. It supports USB, RS-232C, LAN, and GP-IB as communication interfaces. It also supports VISA, a model-agnostic communication driver for instruments. Since it can automatically search for and connect to instruments that are connected to the PC, you can implement the desired control by noting the control commands you wish to execute in the order in an Excel file.

Please prepare the necessary instruments according to the separator characteristics you wish to evaluate.

For details, please see the following site: https://sequencemaker.hioki.com/en/.

Click here to download an Excel sample.

Case 1: Checking separator changes using impedance

(Equipment used: LR8450, IM3536)

Case 2: Checking separator changes using insulation resistance

(Equipment used: LR8450, SM7110)

Measured data

This example plots insulation resistance on the Y-axis and temperature on the X-axis.