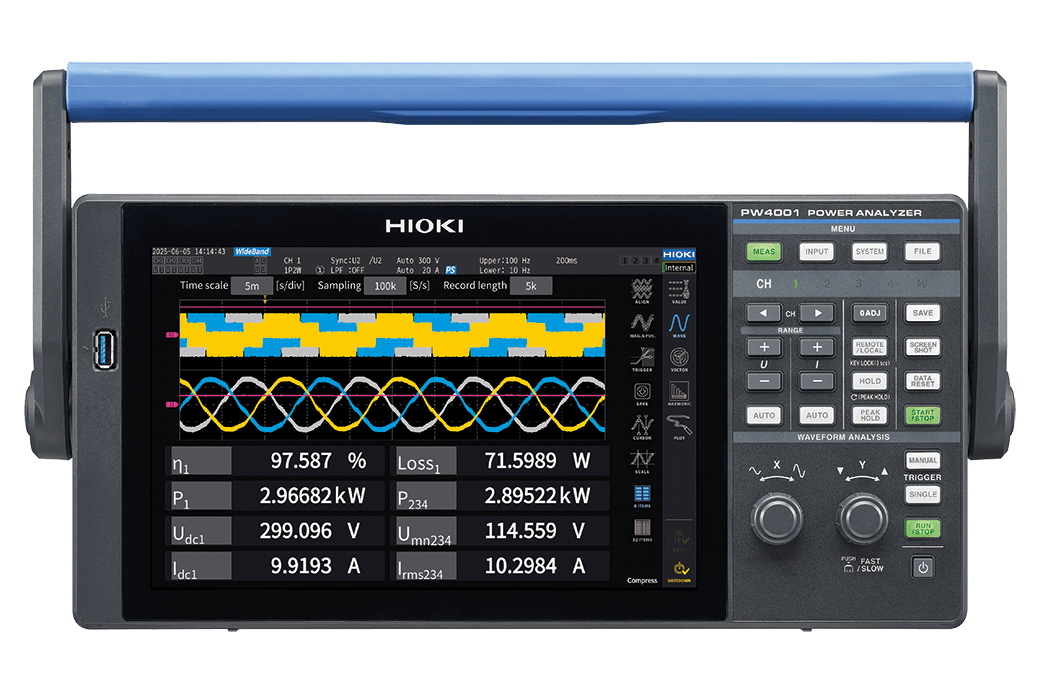

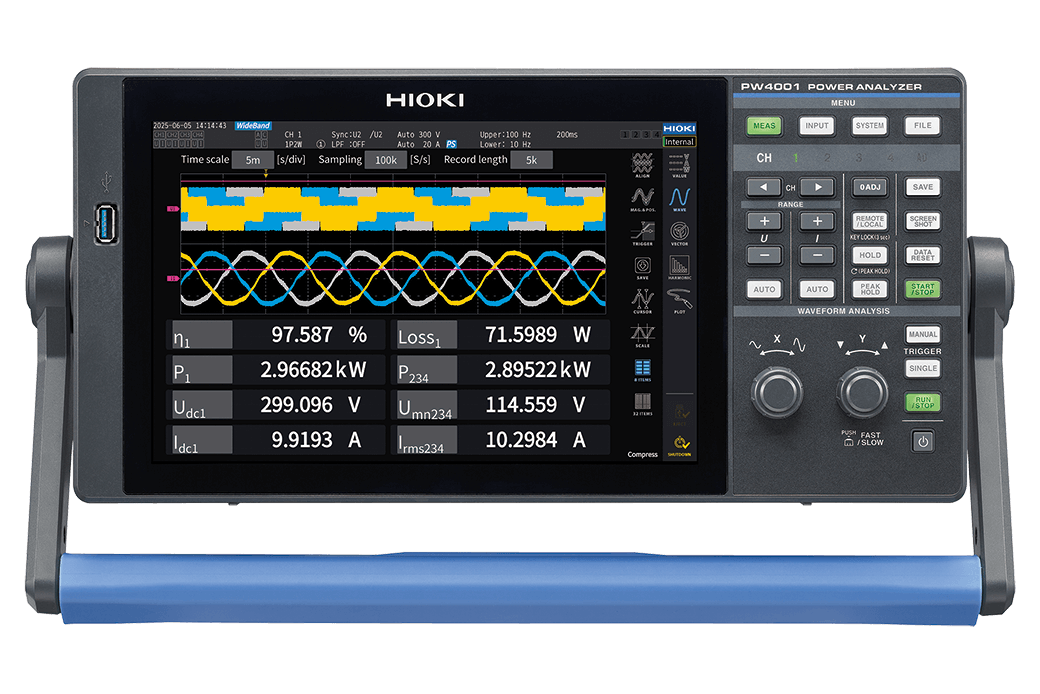

POWER ANALYZER PW4001

Portable 4-channel power analyzer with ±0.04% basic accuracy for vehicle power measurement

NEW

Precision and Portability Perfectly Combined

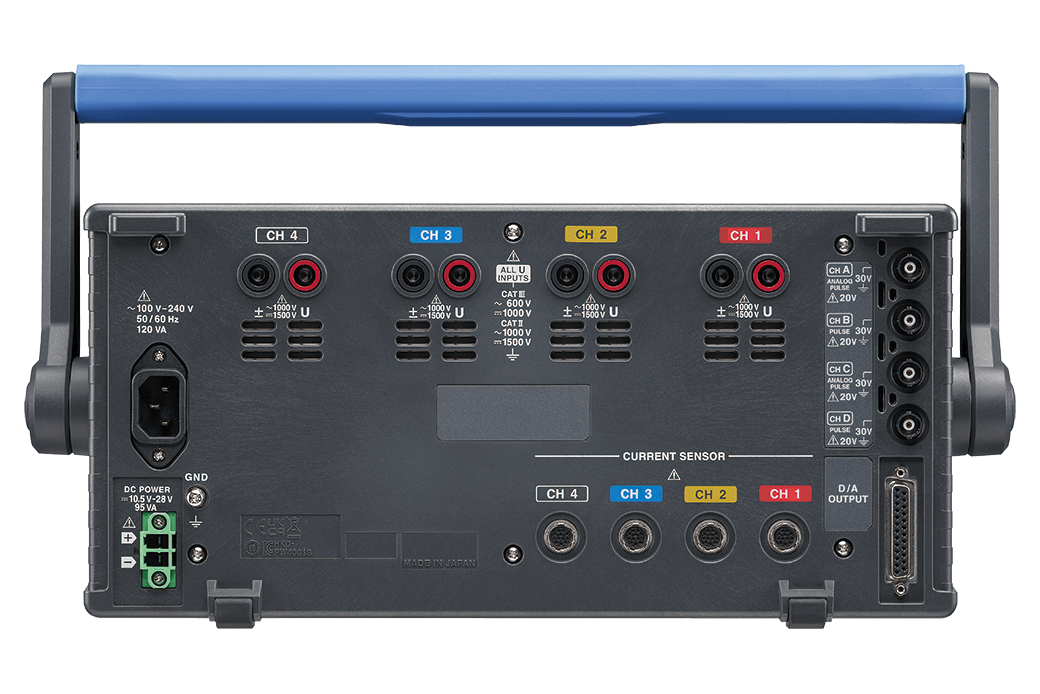

The PW4001 is a high-precision, portable 4-channel power analyzer that offers Hioki’s highest-ever DC accuracy of ±0.04%. Additionally, its measurement bandwidth extends up to 600 kHz, with accuracy specifications maintained across this entire frequency range, ensuring reliable performance from DC to high-frequency applications. Despite its portability, it delivers the measurement accuracy required in research and development as well as in production environments, making it equally suitable for field testing, laboratory evaluation, and production line inspection.

Key Features

- Basic accuracy: ±0.04%

- Operatable temperature range: -20°C to 50°C

- Frequency bandwidth: DC, 0.1 Hz to 600 kHz

- CAN / CAN FD output and input

- Auto phase shift correction for Hioki current sensors

Model No. (Order Code)

| PW4001-01 | |

|---|---|

| PW4001-02 | D/A output |

| PW4001-03 | Motor analysis |

| PW4001-04 | External power source |

| PW4001-05 | D/A output, Motor analysis, External power source |

Lab-grade precision, Field-ready

From xEV fuel and energy consumption testing to DC-DC converter and inverter efficiency evaluation, as well as motor efficiency analysis, the PW4001 provides exceptional reliability and versatility, making it a new-generation portable power analyzer designed for a wide range of measurement scenarios.

Engineered for the tasks you face, wherever you work

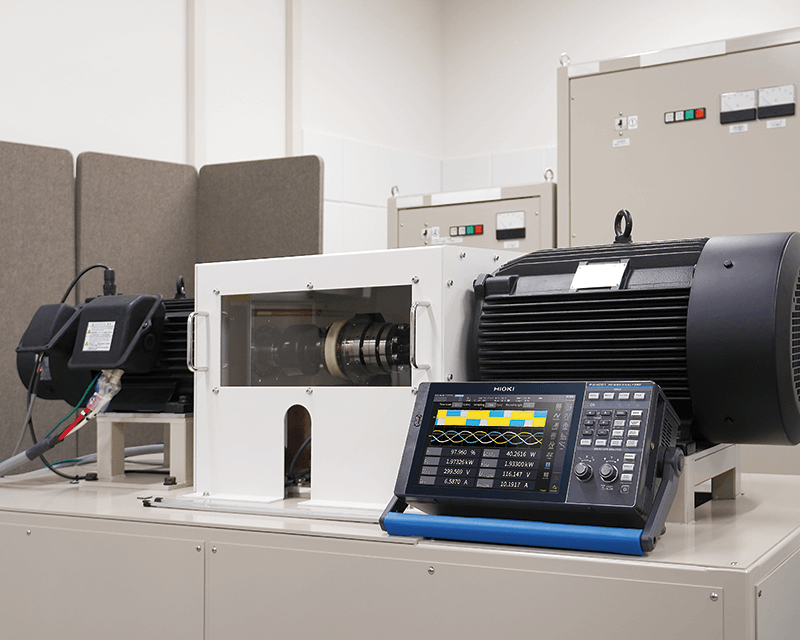

Capture transient power changes with high precision

Evaluate motor and inverter efficiency with 1 ms data updates and 600 kHz bandwidth. Even transient power losses are measured accurately.

・Capture motor power fluctuations with millisecond precision

・Evaluate efficiency for high-frequency inverters

・Automatically detect charge and regeneration to calculate efficiency

Reduce setup time in drive range testing

Ensure accurate measurements even at -7°C. With direct CAN voltage input and flexible, vehicle-side installation, test setup is faster and safer.

・Accuracy maintained at -7°C. Install directly in cold chambers

・Use a compact setup near the vehicle and expand channels with synced units

・Acquire battery voltage via CAN, safe and simple

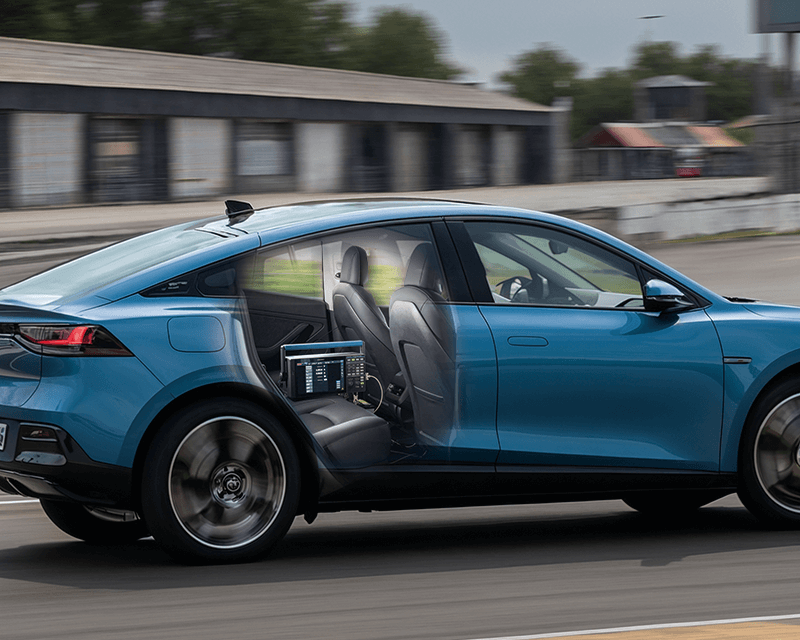

Use it on the road Designed for real-world driving tests

Measure power without vehicle modification. OBD-II input and 10.5 V to 28 V DC power supply make in-vehicle use easy.

・Operates from −20°C to +50°C, ready for harsh environments

・Run on DC power for easy in-vehicle installation

・Use OBD-II CAN bus for safe, real-time vehicle data acquisition

Ensure production quality with waveforms and numbers

Combining waveforms and numerical values ensures reliable, quantifiable quality in mass production.

・Verify efficiency with ±0.04% accuracy at DC and 50 Hz/60 Hz

・Direct voltage input up to 1500 V DC

・2.5 MHz sampling enables waveform evaluation of switching events

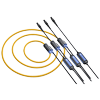

Half the Size, Maximum Precision

The slim design clamp current sensor ensures easy installation even in tight spaces.

Complex tasks in the engine room become simple and efficient, dramatically reducing preparation time for fuel efficiency and performance testing. Not only does it reduce setup time, but it also minimizes the risk of sensor damage from forced clamping between narrow spaces.

Fully compliant with the WLTP and SAE J1634 standards, it provides precise AC/DC current measurements up to 200 A with an impressive DC accuracy of 0.07%.

Basic specifications

| Measurement lines | Single-phase 2-wire, single-phase 3-wire, three-phase 3-wire, three-phase 4-wire | |||||

|---|---|---|---|---|---|---|

| Number of channels | 4 (4 voltage, 4 current, isolated between each channel) | |||||

| Measurement frequency bandwidth | DC, 0.1 Hz to 600 kHz | |||||

| Sampling | 16 bit, 2.5 MHz | |||||

| Data update rate | 1 ms, 10 ms, 50 ms, 200 ms | |||||

| Accuracy for power | DC, 50/60 Hz: ±0.03 % reading ± 0.01 % range / 50 kHz: ±0.40 % reading ± 0.10 % range | |||||

| Voltage measurement range | 6 V, 15 V, 30 V, 60 V, 150 V, 300 V, 600 V, 1500 V | |||||

| Current measurement range | 40 mA to 2000 A (depends on current sensor) | |||||

| Measurement parameters | Voltage (U), current (I), active power (P), apparent power (S), reactive power (Q), power factor (λ), phase angle (φ), voltage frequency (fU), current frequency (fI), efficiency (η), loss (Loss), voltage ripple factor (Urf), current ripple factor (Irf), current integration (Ih), power integration (WP), voltage peak (Upk), current peak (Ipk) | |||||

| Harmonic measurement | Wideband mode: max. analysis order of 500th | |||||

| Waveform recording | Recording capacity: up to 5 mega-words for any waveform (current, voltage, motor) | |||||

| Motor analysis (option) | Voltage, torque, RPM, frequency, slip, motor-power power spectrum analysis | |||||

| Calculation function | Efficiency-loss calculations, user-defined formula, delta conversion, current sensor automatic phase shift compensation | |||||

| External interface | USB flash drive, LAN, USB (function), external control, BNC sync., CAN or CAN FD | |||||

| Power supplies | 100 V to 240 V AC, 10.5 V to 28 V DC | |||||

| Dimensions and weight | 361 (W) × 176 (H) × 135 (D) mm (14.21 × 6.93 × 5.31 in), 4.6 kg (162.3 oz.) | |||||

| Included accessories | Startup guide ×1, power cord ×1, USB cable ×1, D-sub connector ×1 (PW4001-02, PW4001-05), DC power supply connector (PW4001-04, -05) | |||||

Direct Current Input (1)

* To connect to the HIOKI ME15W (12 pin) terminal

Up to 200 A (High precision) (10)

To connect to the Hioki ME15W (12 pin) terminal

Up to 500 A (High precision) (5)

To connect to the Hioki ME15W (12 pin) terminal

Up to 2000 A (High precision) (3)

To connect to the Hioki ME15W (12 pin) terminal

Up to 8000 A (High precision) (2)

Aggregate and measure large currents in multi-cable circuits

Use multiple AC/DC Current Sensor CT6877A units with the Sensor Unit CT9557 to measure currents of up to 8000 A in multi-cable circuits. Requires 1 connection cable to connect the PW6001/PW4001 to the CT9557.

ME15W (12 pin) terminal to ME15W (12 pin) terminal, 1 m (3.28 ft) length (for connecting CT9557 total output to PW6001 or PW3390 only)

PL23 (10 pin) - ME15W (12 pin) conversion (1)

When using a PL23 terminal sensor without “-05” in the model number, Conversion Cable CT9900 must be used to connect to ME15W terminal.

When using the CT6865 and CT6846 (without “-05”), connection via the CT9900 and manual settings are required on the main device.

Convert PL23 (10-pin) terminal to ME15W (12-pin) terminal

Current Input 2000A AC/DC (3)

The CT9920 is necessary for connecting the current sensor with Hioki PL14 to the PW4001

Required to connect the PW3390 or other instrument’s ME15W terminal to a current sensor with a PL14 output connector.

Current Input 6000A (2)

The CT9920 is necessary for connecting the current sensor with Hioki PL14 to the PW4001

Required to connect the PW3390 or other instrument’s ME15W terminal to a current sensor with a PL14 output connector.

Voltage Input (8)

Red/ Yellow/ Blue/ Gray each 1, Black 4, 3m (9.84ft) length, Alligator clip ×8

Banana branch-banana, Red: 1, 0.5 m (1.64 ft) length, for branching from the L9438s or L1000s, CAT IV 600 V, CAT III 1000 V

Banana branch-banana, Black: 1, 0.5 m (1.64 ft) length, for branching from the L9438s or L1000s, CAT IV 600 V, CAT III 1000 V

1500 V DC CAT II, 1 A, 1000 V CAT III , 1 A, banana - banana (red, black each1), alligator clip, approx. 3 m (9.84 ft) length

3.0 m

Attaches to the tip of the banana plug cable, Red/Black: 1 each, 185 mm (7.28 in.) length, CAT II 1000 V

1000 V specifications, Black/ Red, 3 m (9.84 ft) length, Alligator clip ×2

Connection Options (11)

5 m (16.41 ft) length, ME15W (12 pin) - ME15W (12 pin) connector

D-sub 25-pin/BNC (male) 20-channel conversion cable

Attaches to the tip of the L4930/4940, CAT IV 600 V, CAT III 1000 V

Banana plug - banana plug, 1.5 m (4.92 ft) length, red/black each 1

Cord has insulated BNC connectors at both ends, 1.6 m (5.25 ft) length

Cord has insulated BNC connectors at both ends, 3.0 m (9.84 ft) length

Cord has insulated BNC connectors at both ends, 10 m (32.81 ft) length

1.2 m (3.94 ft) length

D-sub 25-pin/BNC (female) 20-channel conversion box

Cord has metallic BNC connectors at both ends, use at metallic terminal, 1.5 m (4.92 ft) length

Unprocessed on one end, 1.8 m (5.9 ft.)

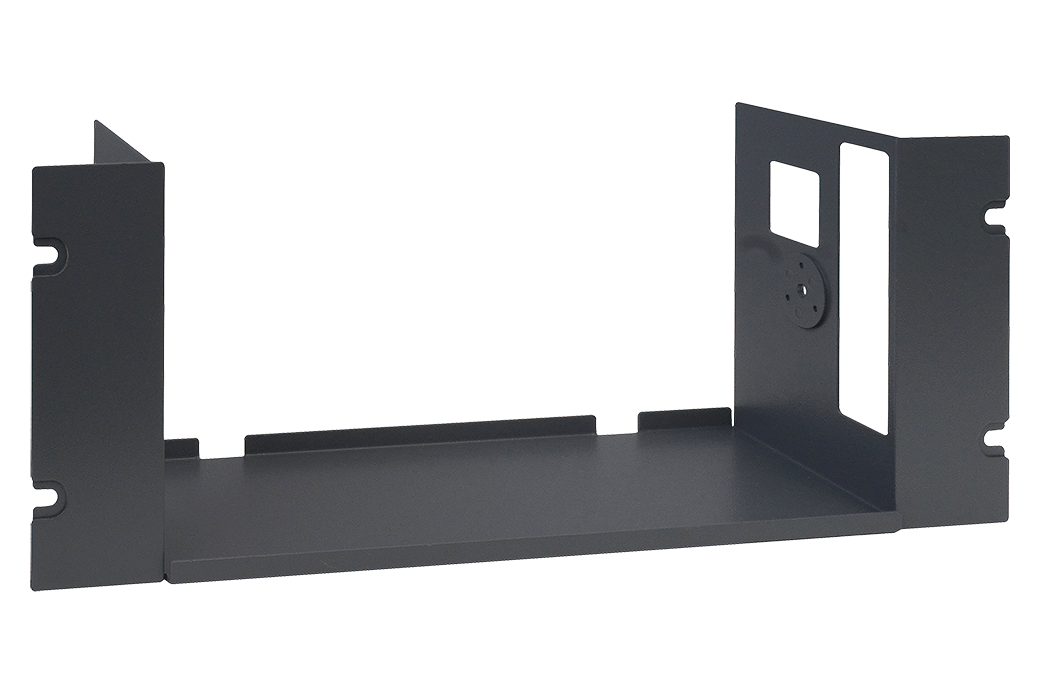

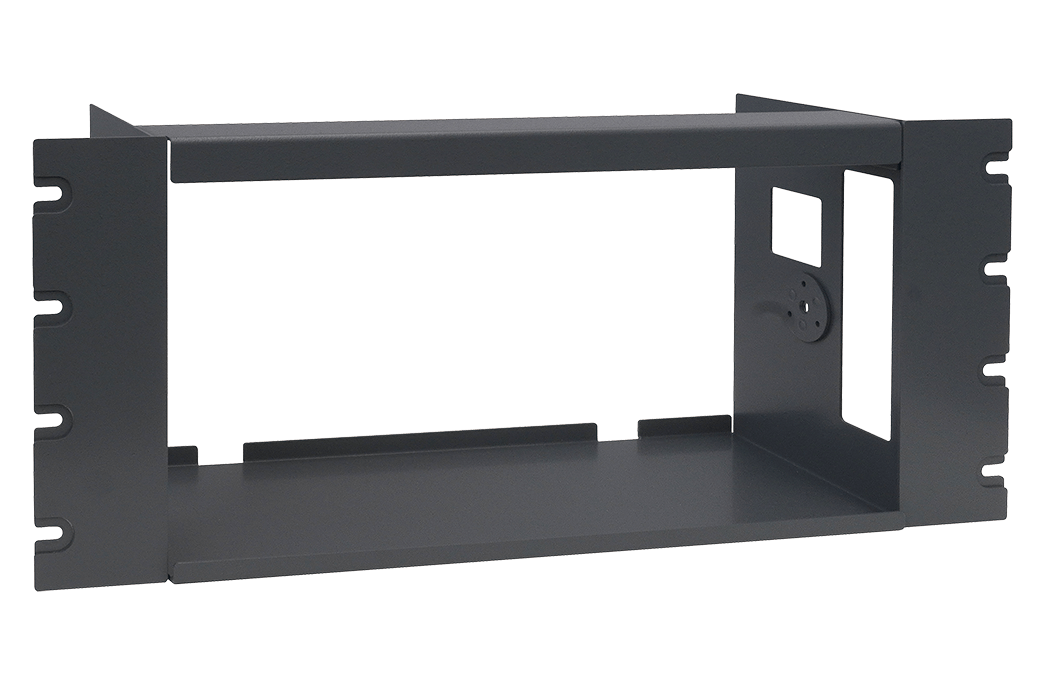

Carrying case (1)

Hard trunk type

Other options (2)

For EIA standard rack

For JIS standard rack

- Durability Assessment of Motors Based on Temperature and Power Data in Endurance Testing

- How Do You Measure a 0.1% Efficiency Improvement in ESS DC-DC Converters?

- Oscilloscope or Power Analyzer? Make the Right Call

- Simplify RDE Testing with Seamless Energy Consumption Analysis

- Simplifying WLTP and SAE J1634 measurements for engineers