Evaluating the Performance of AWD Dual-motors

All-wheel drive (AWD) Dual-motors are attracting attention as drive systems for electric vehicles (EVs). This application note describes how to evaluate the performance of an AWD dual-motor setup by simultaneously measuring the power of two motors along with power input and output for each motor’s inverter and then calculating power conversion efficiency and loss.

Market trends

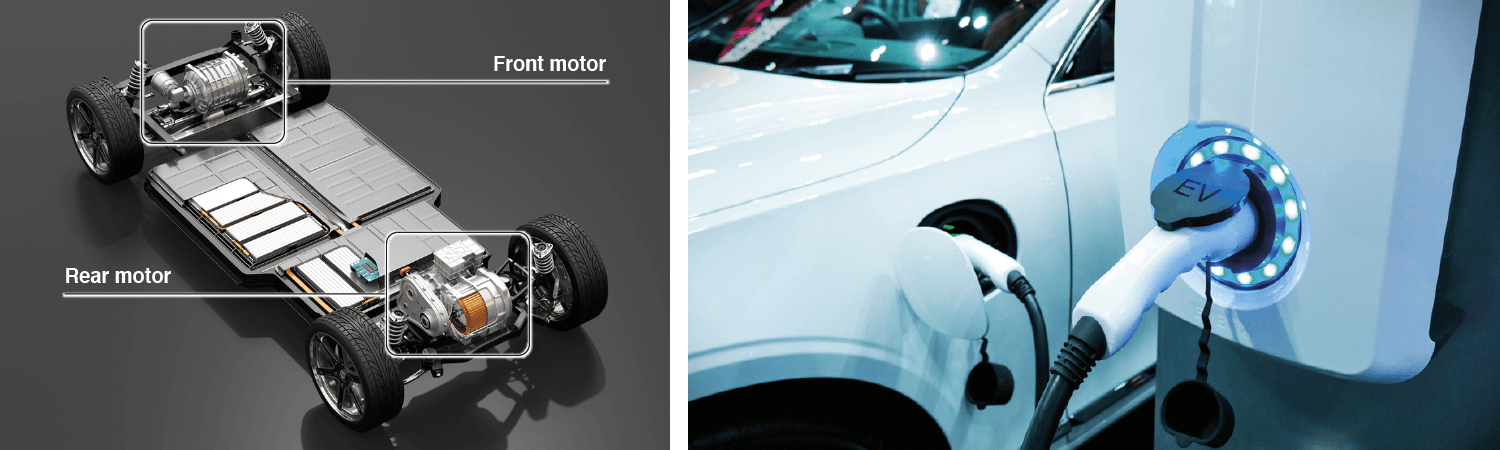

In recent years, AWD dual-motors have been attracting attention as EV drive systems. Dual-motor AWD uses two motors (one in the front and one in the rear) on a single vehicle chassis to implement AWD. The front motor provides drive power for the front wheels, while the rear motor provides drive power for the rear wheels, offering an unprecedented level of acceleration. The arrangement also eliminates constraints imposed by the need for a mechanical connection between the front and rear, allowing vehicles to flexibly allocate drive power to the front and rear as dictated by road conditions. This results in improved handling and reduced energy loss.

Issues

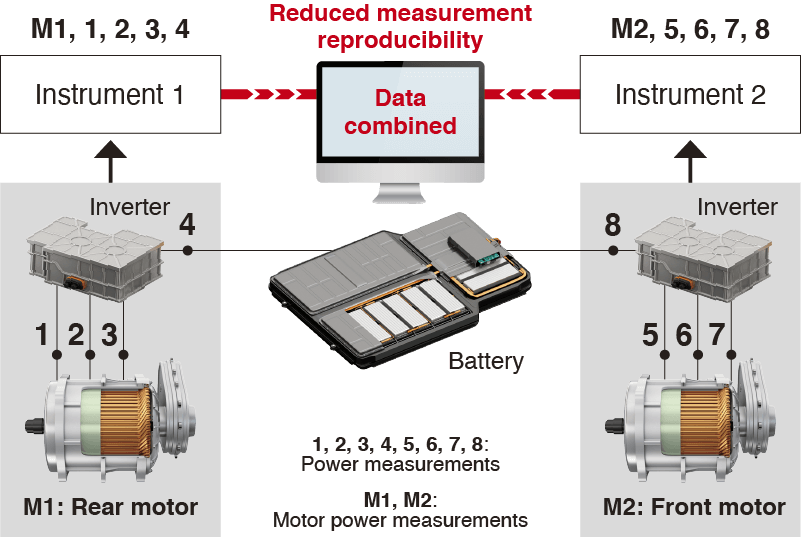

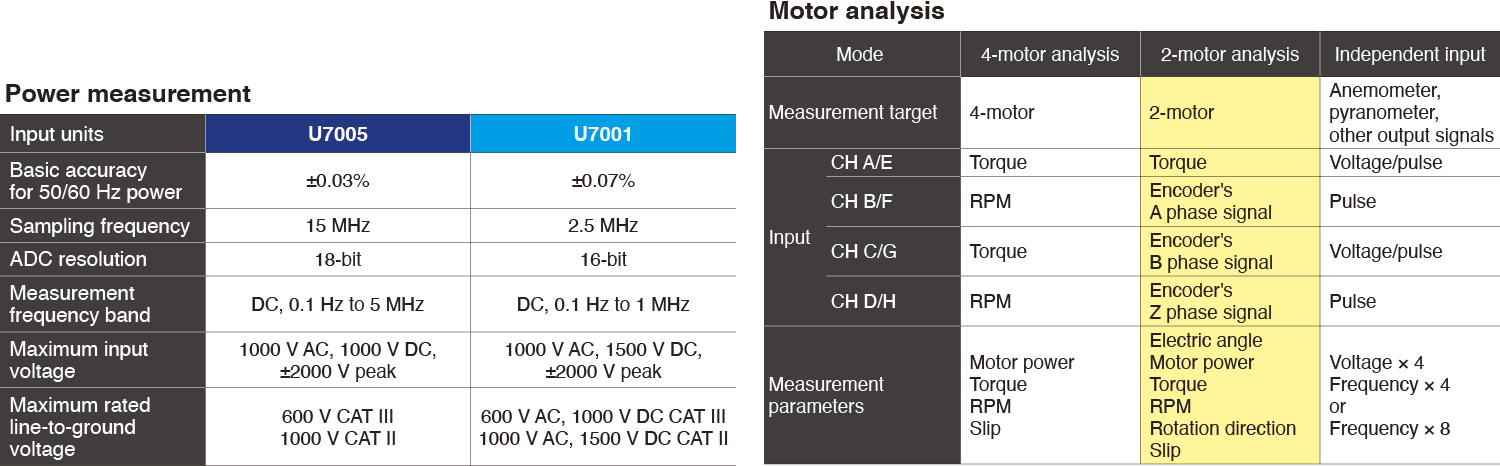

In AWD dual-motor setups, it’s important that the front and rear drivetrain components interoperate. To evaluate the performance of such systems, front and rear motor power as well as power inputs and outputs for each motor’s inverter are all measured as part of a single time series, then power conversion efficiency and loss are calculated. As a result, the process may require use of multiple instruments if one instrument does not provide enough measurement channels. When using multiple instruments, it’s necessary to combine measurement results after the fact, making analysis more time-consuming and contributing to degraded measurement reproducibility.

Solution

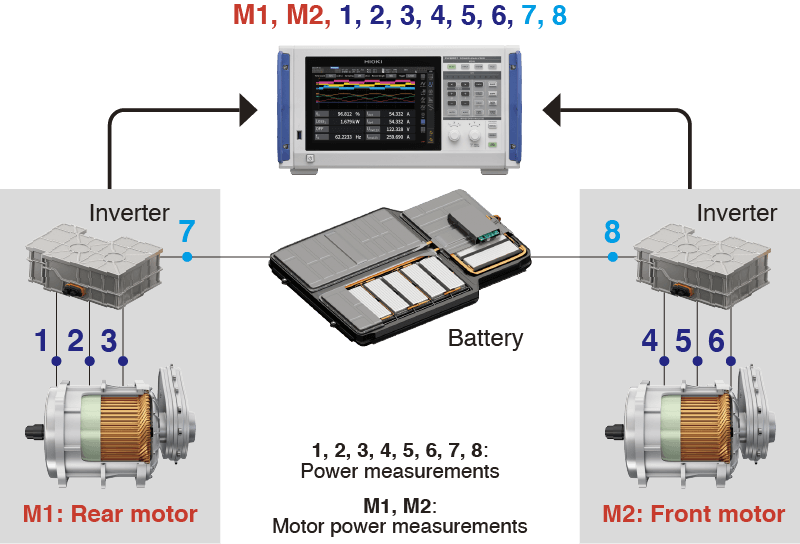

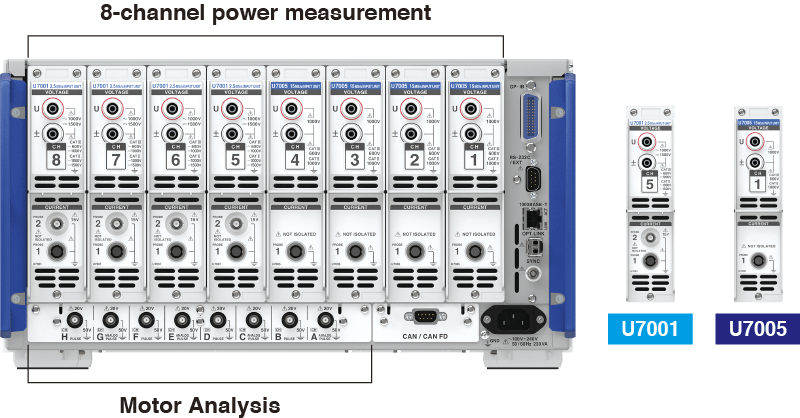

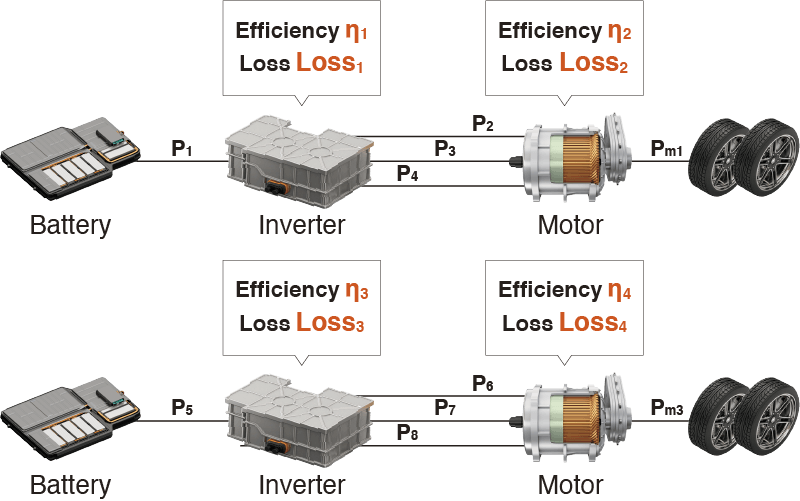

The Power Analyzer PW8001 can simultaneously measure eight channels of power data and two motor power parameters (two torque circuits and two encoder output circuits). As a result, the instrument can measure AWD dual-motor performance efficiently and with a high degree of reproducibility.

Current sensor phase correction: A key capability for power measurement

For power measurements in which accuracy is a key consideration, it’s necessary to choose a current sensor for which phase accuracy has been defined. Additionally, one characteristic of all current sensors is for phase error to increase with frequency. However, Hioki's position as a designer/ manufacturer of both current sensors and power measurement instrument allows it to provide the world with a unique solution to this phase error problem. Hioki has long since been a market leader with the ability for it's power measurement devices to offset its high accuracy sensors' fine-tuned phase characteristics. Furthermore, now with the new Power Analyzer PW8001, when you connect a current sensor, the instrument automatically ensures accurate power measurement by detecting the sensor's model and correcting its phase characteristics*. (*Current sensors with automatic phase correction functionality only.)

Rated current: 20 A to 2000 A

Hioki’s line of current sensors supports a broad range of measurement, from minuscule currents to large currents.

Measurement data

In the following experiment, Hioki used a Power Analyzer PW8001-11 (with motor analysis function) and Hioki's high accuracy current sensors to measure the power of two motors (front and rear) as well as the power inputs and outputs for each motor’s inverter to determine the power conversion efficiency and loss for each motor system.

Finally

In summary, the AWD dual-motor system is garnering significant attention within the electric vehicle sector due to its potential contributions. The PW8001 can efficiently evaluates AWD dual-motor performance by simultaneously analyzing eight power data channels and two critical motor parameters—torque and encoder outputs. This precise and consistent assessment is fostering increased interest in the adoption of AWD dual-motor technology in electric vehicles. For additional product information, visit the PW8001 product page or speak with a specialist.