Measure the Insulation Resistance of Electric Vehicles

Battery electric vehicles (BEVs) are becoming more popular in today's world as it pushes toward decarbonization. BEVs, like internal combustion engine vehicles, require service to keep them running. Insulation resistance testing is an essential part of maintenance and inspection to prevent electric shocks from BEVs. This is especially true since the test checks for proper insulation that protects from the dangerously high voltages of EVs. Furthermore, this test will continue to grow in importance as the EV market keeps increasing the voltages of EVs year-on-year. In this application note, we will go over insulation resistance tests for maintenance and inspection os BEVs.

Note: For details on the procedure of how to conduct insulation resistance tests on an electric vehicle, please check with the vehicle manufacturer

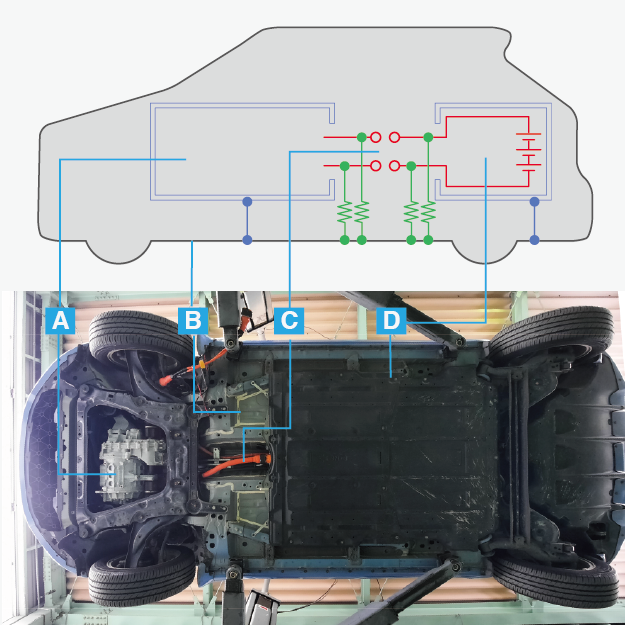

Insulation measurement flow

In this test, we verify that there are no flaws in the insulation between the high-voltage (HV) system and the ground. For reference, the locations of the measurements are labeled as follows:

- A: Inverter, motor, etc.

- B: Chassis

- C: HV cable

- D: HV batteries

The flow of insulation testing is as follows:

- 1.Be sure to shut down*1 the vehicle's HV system by disconnecting the service plug or switch before carrying out any electrical testing or measurements.

- 2.After performing the zero-voltage measurement and other safety procedures, which confirm that the vehicle is completely shut down, one can proceed with the insulation test.

- 3.The test voltage applied during the insulation measurement must be higher than the vehicle’s battery voltage. When measuring insulation resistance with the HIOKI insulation tester, for instance, use the 500 V range if the HV battery of the vehicle is 400 V. Please keep in mind that the test voltage may vary based on the vehicle model.

- 4.Judge good or bad insulation based on the insulation resistance value specified for the vehicle model by the manufacturer.

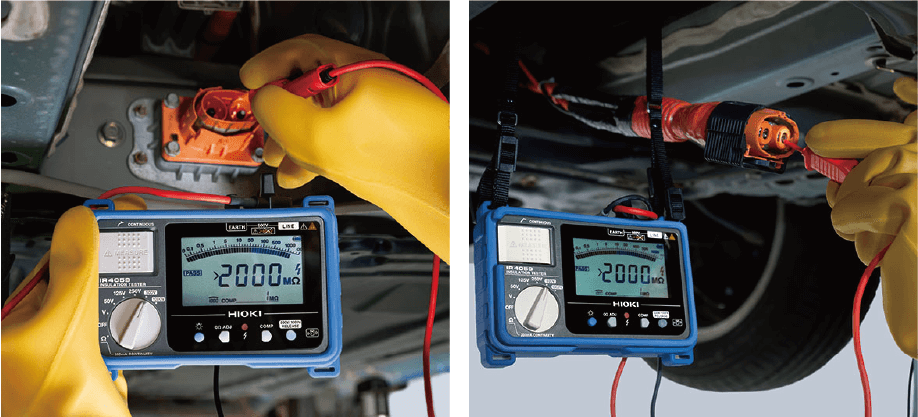

- 5.As shown in Table 1, tests are done on both the connector of the HV battery (HV battery side) and the connector of the inverter (inverter side). The test is carried out between each of the side's HV cable connectors (battery and inverter) and the chassis ground of the vehicle. Since there is a diode on the inverter side, it is necessary to switch the polarity, so the test is performed twice.

- *1: The removal of high-voltage components is hazardous work. Ensure that qualified personnel specified by the laws and regulations with professional training perform the work. For details, please follow the operation manual of each vehicle manufacturer.

Table 1: Test points

| Test point | Positive terminal of insulation tester (+) | Negative terminal of insulation tester(−) |

|---|---|---|

| HV battery side | Postive terminal of the connector (+) | Ground |

| Negative terminal of the connector (−) | Ground | |

| Inverter side | Postive terminal of the connector (+) | Ground |

| Negative terminal of the connector (−) | Ground | |

| Ground | Postive terminal of the connector (+) | |

| Ground | Negative terminal of the connector (−) |

Insulation test on the HV battery side (left figure) and inverter side (right figure)

Insulation test on the HV battery side (left figure) and inverter side (right figure)

For safer and more efficient measurements

Next, we will take a look at Hioki's IR4059 insulation resistance tester, including its features and why it is a good choice for measuring BEV insulation.

1. For the HV range (500 V or 1000 V), the IR4059 has a safety feature that requires the technician to unlock in addition to choosing the voltage to prevent erroneous operation of applying high-voltage to low-voltage equipment.

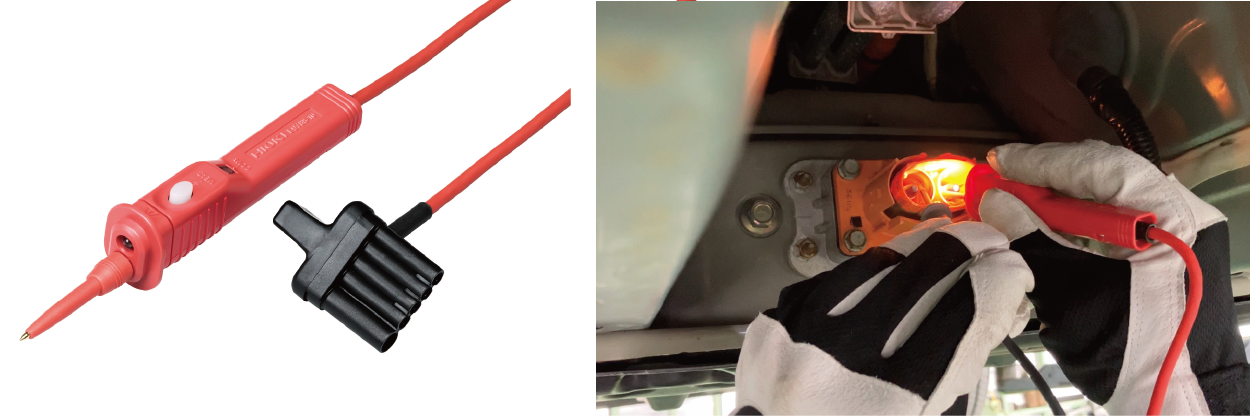

2. The test lead with remote switch (included), L9788-10, allows you to start and stop the measurement at your fingertips. It is equipped with an LED, which helps with visibility and instantaneous pass/fail judgments while the measurement is in progress.

3. The HV cable is unstable during insulation testing, making it difficult to securely probe the connector terminals. With the IR4059, continuous measurement and high-speed measurement (response time of 0.3 seconds) can make measurement stress-free.

4. With the magnetic strap Z5020 securing the insulation tester to the vehicle, you can perform the insulation test while checking the reading at the eye level.

5. Installing the Wireless Adapter Z3210 to the IR4059 allows Bluetooth® connection. By connecting the instrument to the mobile app GENNECT Cross, you can digitize and manage your measurement data. By storing the data and comparing them at the annual inspection, it is possible to take preventative actions against insulation deterioration of the BEV.

Finally

Technicians play a crucial role in conducting essential electrical tests and mechanical inspections for EV maintenance. Notably, the insulation resistance test stands as a cornerstone for ensuring vehicle safety. The IR4059 shines with safety and user-friendly features, streamlining technician tasks effortlessly. For further information on the instrument and the measurements utilized to ensure BEV safety, please do not hesitate to visit the product page or contact us. HIOKI provides solutions for the safe and effective maintenance of BEVs.