Power Quality Analysis Procedure: 4 Must-Know Tips

Investigate and analyze power quality issues

Steady, high-quality power supply is not only about availability, but also about power quality. However, identifying the root causes of power quality issues—ranging from harmonic distortions and voltage fluctuations to the effects of lightning strikes and equipment failures—can be a complex challenge. These disturbances, often invisible to the naked eye, can lead to equipment malfunctions, operational downtime, and even safety hazards. Conducting a thorough power quality survey is the first step towards analyzing and mitigating these issues, thereby enhancing the overall performance of electrical systems.

This article provides useful tips and gists for conducting power quality surveys and analysis and identifying power quality problems. Whether you are a facility manager, an electrical engineer, or simply interested in electrical system optimization, these guidelines will serve as an essential tool in your efforts to ensure a stable and high-quality power supply.

Before Getting Started

Preparation is Key

Before diving into the measurements for a power quality survey, gathering detailed information about the site is essential. This foundational knowledge allows for a more accurate assessment and identification of potential improvement areas.

The following information must be collected.

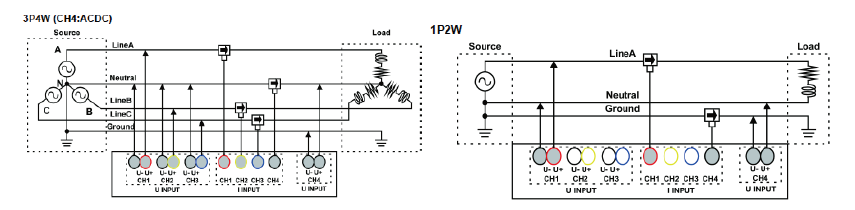

- Circuit wiring

- Determine if the site operates on 3-phase or single-phase power.

- Check for the presence of a neutral line.

- Identify any mixed circuit wiring, such as 3-phase circuits divided into single phases.

- Nominal supply voltage

- Confirm the nominal supply voltage(s) — 110 V, 220 V, 440 V, etc.

- Note if there are multiple power lines with different voltages, for instance, a higher voltage dedicated to the other A/C system.

- Frequency

- While most power supplies operate at 50 Hz or 60 Hz, exceptions exist. Specialized systems, like those in airplanes or ships, may operate at frequencies up to 400 Hz. It is crucial to verify the frequency of your power lines.

- Current capacity

- Grasping the current capacity within the system you're measuring is crucial. It aids in selecting the appropriate current sensors for the measurement, ultimately enhancing the accuracy and efficiency of your surveys.

- Additional site information

- Other information about the building, such as hours of operating key electronic equipment and what equipment has been added or removed, etc.

This comprehensive approach to pre-survey preparation ensures a thorough and effective power quality analysis, setting the stage for actionable insights and improvements.

Steps to Analyzing Power Quality Issues

Finding the root cause of power quality problems can be difficult. The following few tips can help with power quality measurements. Here are 4 tips to help you measure power quality.

1. What?

Understanding is the key to resolving troubleshooting caused by power quality problems. First, we need to know what type of trouble is occurring. A tip is to look for heat or unusual noises coming from the equipment.

2. When?

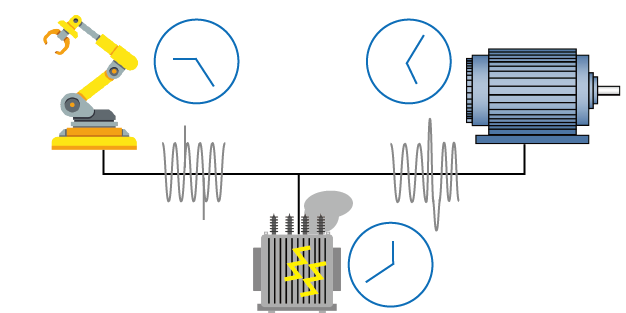

Next, it is necessary to know when the trouble occurred. Is it cyclical or intermittent? It is better if specific dates and times are known. If an event is recorded, the trouble could be caused by equipment that is running or restarting at that time of day. Knowing exactly what time the event occurred and when the trouble subsided will make it easier to determine which equipment or location caused the trouble.

3. Where?

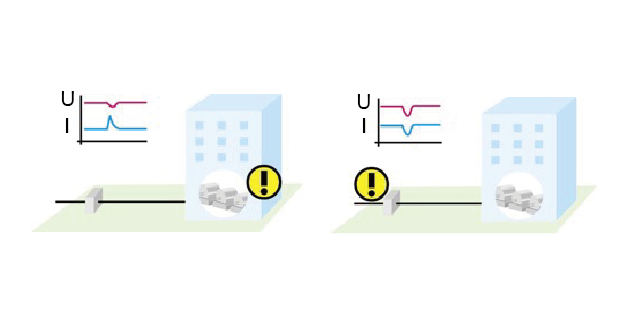

The next step is to identify the measurement location. For example, if measurements are taken at a receptacle point, the trends in voltage and current may provide useful information. If both voltage and current are falling, the cause can be traced to outside the building. If the voltage is falling, it can be assumed that a short circuit or inrush current caused the problem inside the building. Simultaneous measurements at a number of locations can help identify the cause of the problem.

4. What may be the cause?

Finally, once the measurements have been completed, the root cause of the problem can be deduced. Sort power quality events by specific dates and times, and cross-reference them with site information such as equipment schedules and any recent changes in equipment (additions or removals). This approach can offer valuable clues to pinpoint the cause of issues.

Measurement Tools for Power Quality Analysis

For Measurement

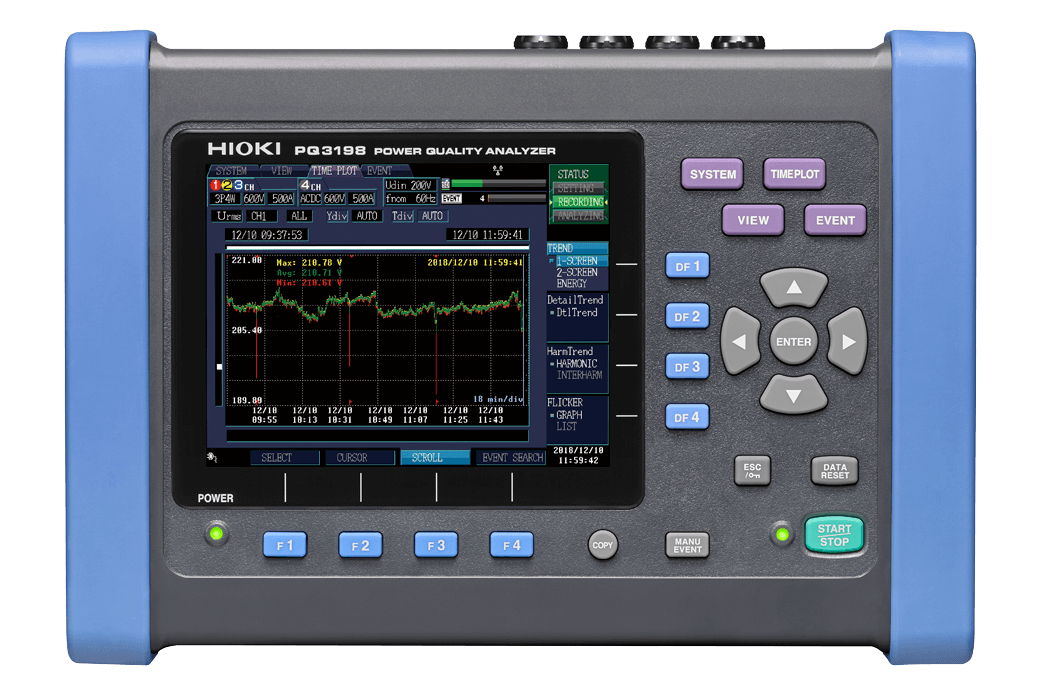

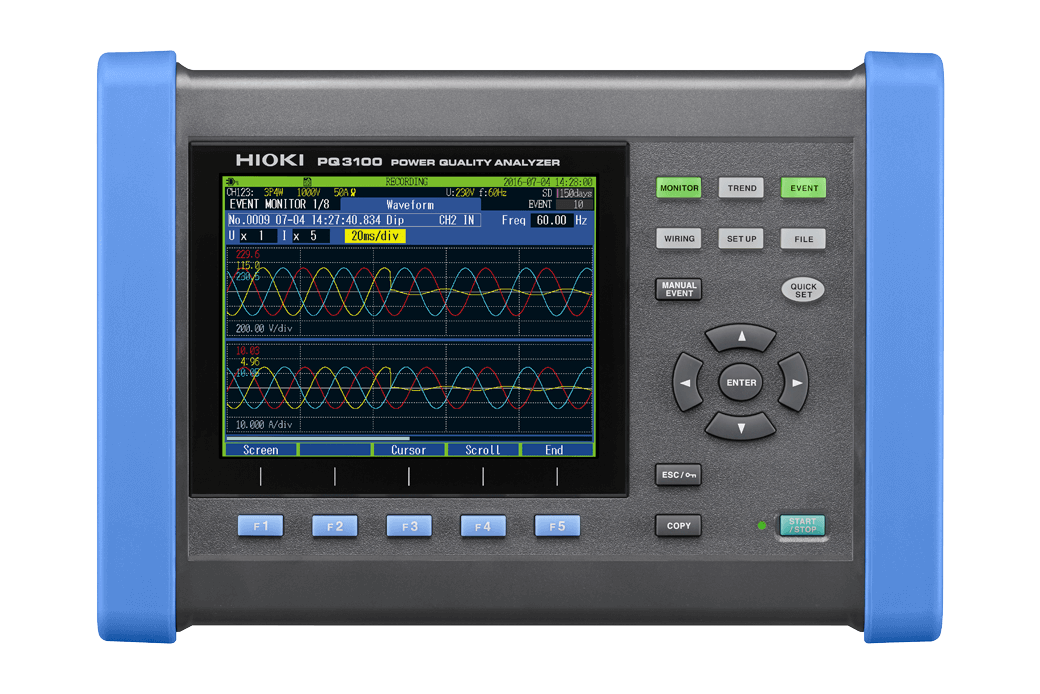

To measure power quality, a specialized power quality analyzer is used. Hioki offers two types of analyzers: the advanced type PQ3198 and the standard type PQ3100. Table 1 gives an overview of the two types.

Table 1: Overview of power quality analyzers

| Product model | PQ3198 | PQ3100 |

|---|---|---|

| Standard compliance |

|

|

| Fundamental frequency | DC/50 Hz/60 Hz/400 Hz | DC/50 Hz/60 Hz |

| Event parameters | Transient, swell, dip, interruption, frequency fluctuation, inrush current, THD | |

Advance event capture features for troubleshooting:

| N/A | |

| Advance transient measurement: 2MS/s, 6 kV | Standard transient measurement: 200kS/s, 2.2 kV | |

| Basic harmonics measurement | ||

| Advanced harmonics measurement | High order harmonics (Supraharmonics) : 2 kHz to 80 kHz | N/A |

| Best for | When it is necessary to investigate, diagnose and countermeasure power supply conditions that cause equipment malfunctions. | Where a power survey needs to be conducted to determine the load size of the system or to determine the power quality of the system. |

For Analyzing

Measuring instruments are only for recording data, while software is needed for analysis. Let me remind you that both are important. The data acquired by Hioki's power quality analyzer can be analysed using software called PQ ONE.

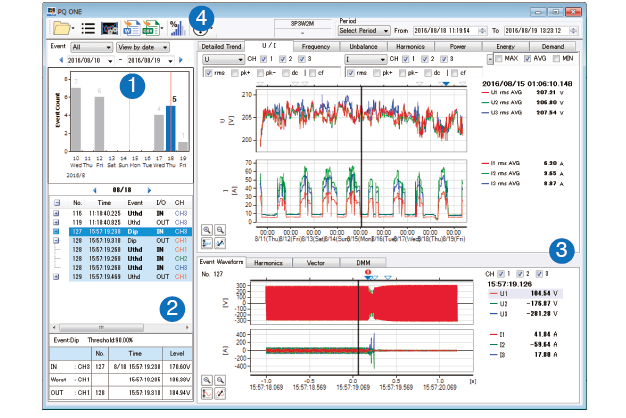

Here are some useful features of PQ ONE in this area:

- 1.Event statistics

- 2.Event list

- 3.Trend graphs and event details

- 4.EN 50160 determination function

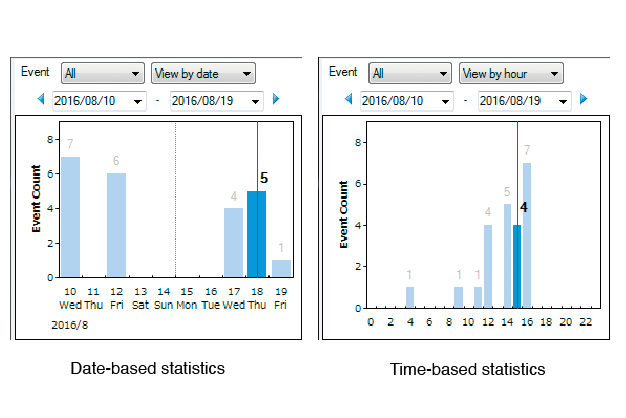

- 1. Event statistics

- Displays event statistics by date or time. This function makes it easy to discover anomalies that occur at specific times of the day or on specific days of the week. Alternatively, anomalies occurring on specific days of the week can be easily detected

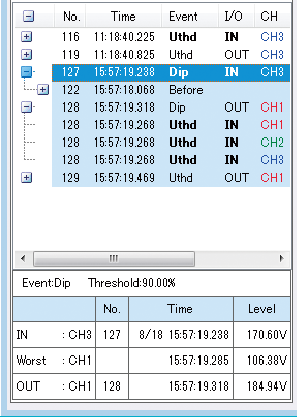

2. Event list

This feature allows you to view all captured events or filter them by specific occurrences, making it simpler to identify power anomalies based on duration and severity.

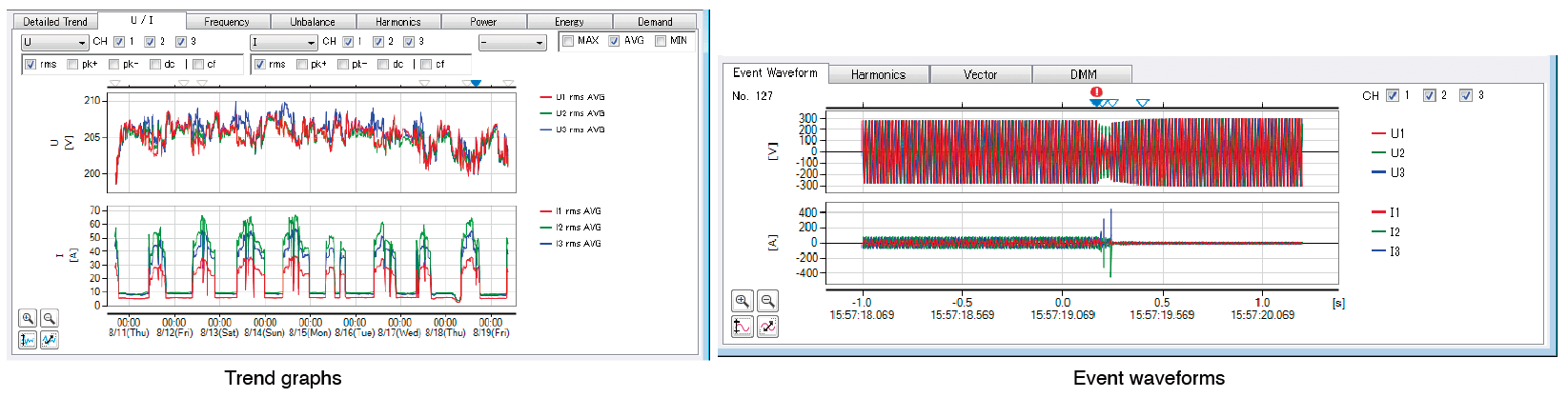

- 3. Trend graphs and Event details

- Trend graphs give an overall picture of the measurement. Trend graphs make it easy to spot anomalies. Event details provide detailed information on the power quality events that occurred during the measurement. It provides details such as event magnitude, time, length and waveform shape. By analysing these data, clues to power quality problems can be found

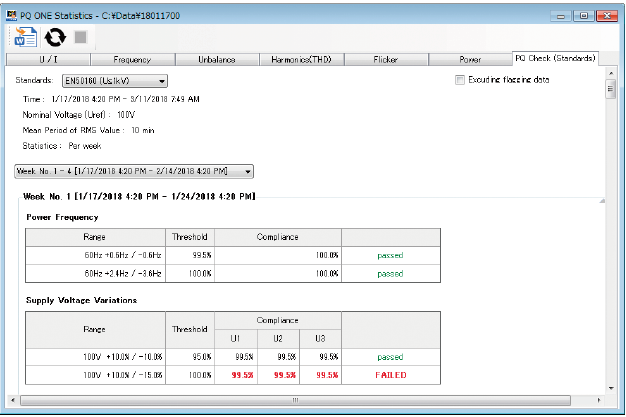

- 4. EN 50160 judgment function

- This function analyses the measurement data and judges whether or not it complies with the EN 50160 standard based on the voltage fluctuations in the trend section. Basically, it judges whether the power quality is good or not.

PQ One software also offers a convenient way to generate reports automatically with just a few clicks.

Finally

By clearly understanding what the true problem is, when and where it occurs, and the causes of those problems, you can take action to mitigate them and improve the power quality on your site. With Hioki’s power quality analyzer, you can diagnose even difficult-to-detect problems in power quality.Contact one of our experts today to find out more about how we can help you improve your production process.