IEC 60851-5 Winding Wire Dielectric Tangent (tanδ) Testing

Enamel wires are used in motor windings. As part of R&D and product inspections by enamel wire manufacturers as well as acceptance inspections and material development by motor manufacturers, engineers test the performance of enamel wire by measuring its dielectric tangent (tanδ) as set forth in IEC 60851-5.

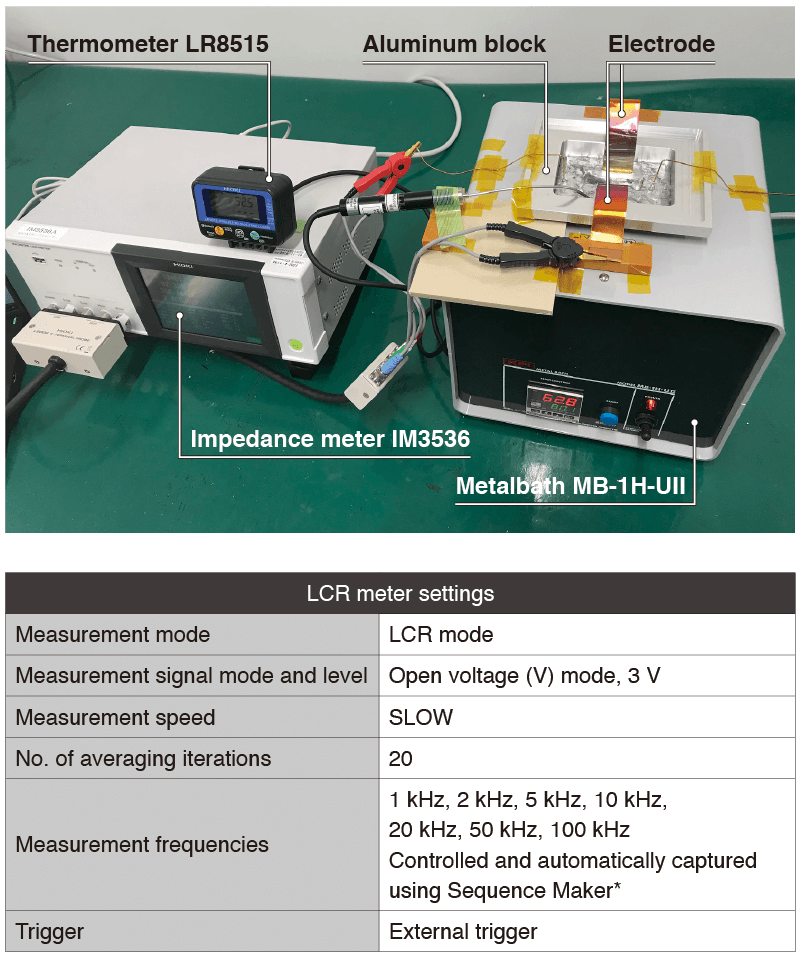

Test equipment and method

Test method

• Perform open correction for the LCR meter before starting the test.

• Insert an enamel wire (with a diameter of 0.9 mm) into melted solder.

• Using a metal bath, increase the temperature of the solder from 40°C in 10°C increments.

• Using the LCR meter, measure the dielectric tangent at each temperature.

• Measure the dielectric tangent at multiple measurement frequencies.

• Perform short correction across the LCR meter’s electrodes at each temperature.

• Record the measurement data using Sequence Maker*.

Here, an “MB-1H-U II” metal bath from Koike Precision Instruments (http://www.k-p-i.net/) is used along with a special-order rimmed aluminum block (to hold the melted solder).

*Sequence Maker is a free Excel® add-in. It can be used to control switching between measurement frequencies for an LCR meter and to collect measurement data from within Excel®. For details, please see the following site: https://sequencemaker.hioki.com/en/.

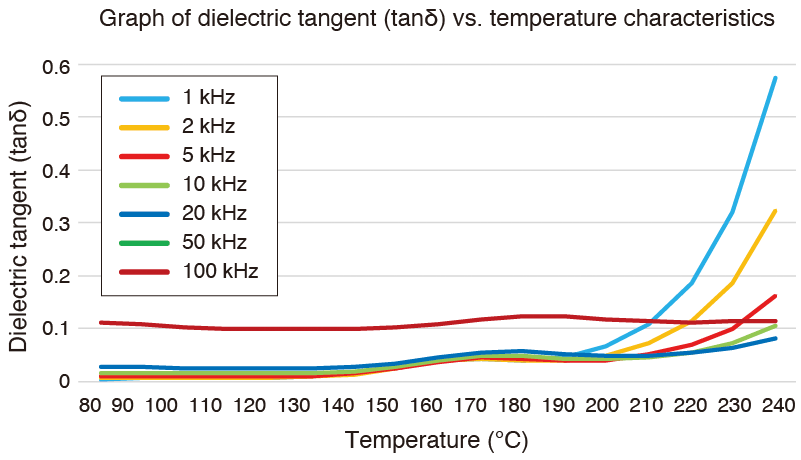

Measurement data

• The tanδ value increases with the measurement frequency.

• At a measurement frequency of 1 kHz, the tanδ value switches from a stable state to rapidly increasing at a temperature of 190°C.

• Higher measurement frequencies result in higher temperatures, which increase rapidly.