Next-Generation Data Logger Ideal for EV Energy & Thermal Management

Introduction

In the development of electric vehicles (EVs), energy management and thermal management are closely interconnected. For instance, in EVs, power consumption from air conditioning affects driving range and performance, making it crucial to minimize energy consumption for heating and cooling. To achieve this, accurately assessing the efficiency of heat pumps and heat recovery systems is essential. It is necessary to measure not only the power consumption but also the amount of heat generated, in order to optimize the overall energy distribution of the vehicle.

Additionally, rapid charging can cause the internal temperature of the battery to rise, which, if left unchecked, may lead to performance degradation and reduced safety. To prevent such issues, it is important to coordinate current control during charging with temperature management through the cooling system.

Thus, to enhance the overall energy efficiency and safety of EVs, it is necessary to monitor power and temperature changes in real-time simultaneously, maintaining an optimal balance between the two. However, in actual development settings, power and temperature are measured using separate devices, leading to significant development time and costs for data synchronization and integration.

What if these data could be synchronized and acquired in real-time and with high precision using a single system? This article will introduce the challenges in energy and thermal management for EVs and the solutions to address them.

Target Customers

- Control development engineers for EV powertrains

- Development engineers for HVAC systems

- Battery management system development engineers

- System integrators for large-scale evaluation systems

Challenges: Inability to Synchronize Power and Temperature Data, Hindering Optimization of Control

To operate EVs efficiently, it is essential to accurately monitor heat generation and energy distribution in real-time. However, many development environments rely on the following equipment configuration:

- Temperature measurement using general-purpose DAQ systems

- Power measurement using separate devices that accommodate high voltage inputs

This configuration leads to several issues:

- Data timestamps do not align, making correlation analysis difficult

- The causal relationship between temperature changes and power changes is unclear

- Data integration and processing after testing take a significant amount of time

Solution: An Integrated System for Simultaneous Measurement of Power and Temperature

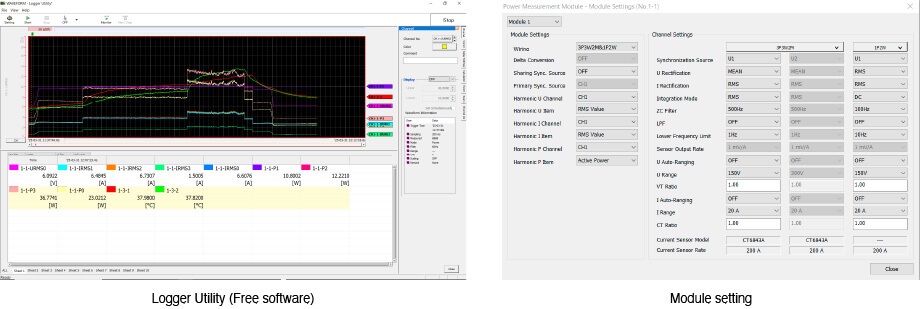

Hioki's modular logger system, the "LR8100 series," along with its expansion units M7103 (for power) and M7100 (for temperature), offers an integrated measurement solution that allows for the synchronized acquisition of power and temperature data.

Key Features

- Power calculations (active power, reactive power, apparent power) with a cycle time as fast as 5 ms

- High-voltage safety design compatible with DC 1500 V

- Thermocouple inputs expandable up to 3000 channels

- Choose the optimal size and rating from a wide range of current sensor options

- Easy integration with higher-level systems via CAN and XCP support

- Power measurement capability for up to 120 channels through synchronization via optical communication

Complex tasks in the engine room become simple and efficient, dramatically reducing preparation time for fuel efficiency and performance testing.

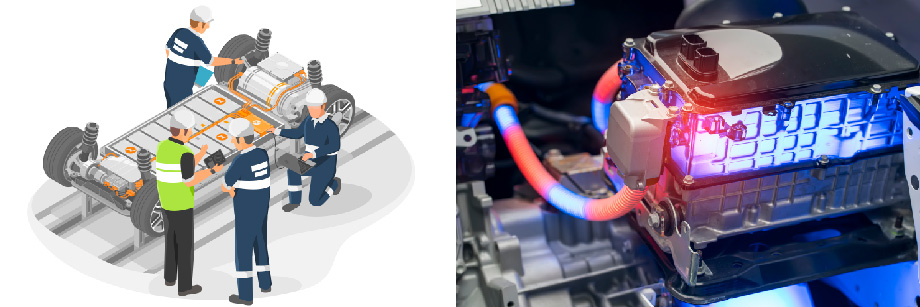

Complex tasks in the engine room become simple and efficient, dramatically reducing preparation time for fuel efficiency and performance testing. Multiple sensors can be easily installed, even in confined spaces and locations with complex wiring.

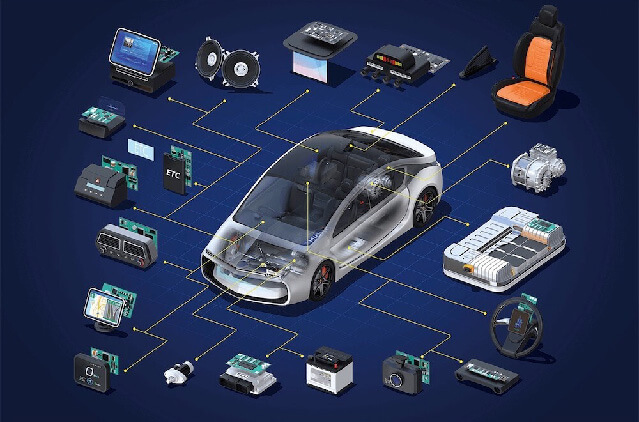

Multiple sensors can be easily installed, even in confined spaces and locations with complex wiring. HIOKI's measurement equipment can be used to measure power at multiple points in various EV components.

HIOKI's measurement equipment can be used to measure power at multiple points in various EV components. Accurately measures battery cell temperature for early overheating detection.

Accurately measures battery cell temperature for early overheating detection. Monitors intake, outlet, and pipe temperatures to support performance and fault detection.

Monitors intake, outlet, and pipe temperatures to support performance and fault detection.

Use Case Introduction

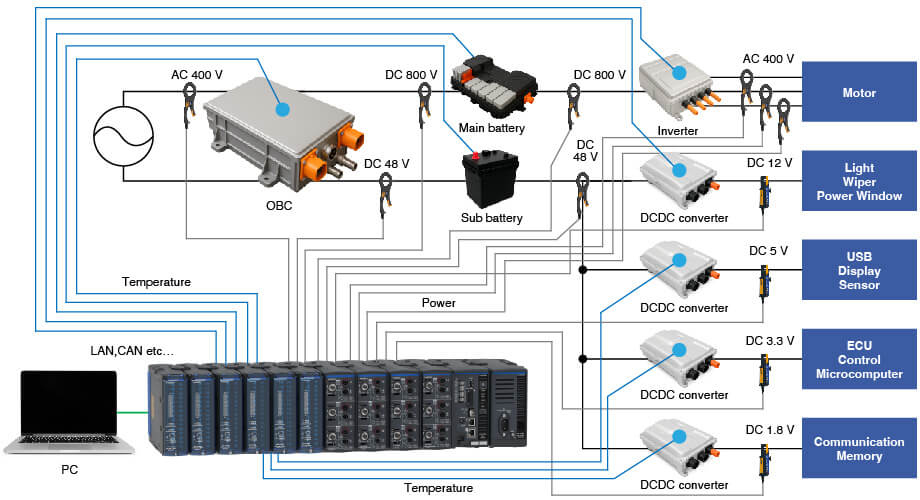

Example: Comprehensive Power Monitoring System

Measurement Targets:

- Efficiency measurement of DC/DC converters

- Power measurement of the battery and various components during various mode operations

- Air vents, inside the vehicle, outside air, and the battery

- Measurement of the vehicle’s overall power consumption

Challenges:

- Power and temperature vary significantly depending on the outside temperature and driving mode.

- It is difficult to identify areas where efficiency decreases, making it challenging to improve the control system.

- There are many measurement points, requiring multiple measuring devices to be prepared.

- The measurement locations within the vehicle are limited, making it difficult to connect numerous current sensors.

- It is difficult to collect vast amounts of measurement data.

Solution:

- Achieve high-precision synchronized measurements of power and temperature with a single machine (LR8100-series logger).

- Record power changes in the battery and components at intervals as short as 5 ms using the M7103.

- Simultaneously measure battery temperature and cooling system temperature with the M7100.

- Enable multi-point measurements in real vehicle environments using the compact and lightweight clamp sensor CT6830-series.

- Output vast amounts of data via CAN for integration into higher-level systems.

- Create a correlation map of temperature and power to optimize control parameters.

Benefits of Implementation:

- Visualizing reduced power consumption helps prevent overcooling by the cooling system.

- The heat map clarifies the trade-off points between cooling performance and driving range.

- Testing in a real-vehicle environment provides accurate measurements of actual thermal losses and aerodynamic performance.

- High-precision power and temperature measurement with a single device.

- Capture rapid power changes at 5 msintervals.

- Simultaneous monitoring of battery and cooling system temperatures.

- Compact sensors enable multi-point measurements and CAN data integration.

Conclusion

Energy management and thermal management in electric vehicles (EVs) play a crucial role in extending driving range, improving charging efficiency, and maintaining thermal comfort. The key to optimization lies in the simultaneous measurement of power and temperature with high precision across multiple channels.

The LR8101 or LR8102 serves as a high-precision data logger capable of simultaneously measuring power and temperature with a single device, providing strong support in addressing these challenges. It transforms the invisible losses in EV development into visible improvements.

Are you ready to take the quality of next-generation EV development to the next level? To discover how Hioki’s LR8102 + M7103 multi-channel logger system can optimize your EV battery cooling and power testing, visit our product page, or request a hands-on demo today.

For detailed product information, please visit our website.

For a demonstration or consultation on a specific application, please contact us using our contact form.