Simplifying WLTP and SAE J1634 measurements for engineers

How can automotive engineers shorten certification test time, reduce operational risks, and maintain compliance with WLTP and EPA (SAE J1634) standards? This article introduces how Hioki’s Power Analyzer enables an innovative measurement approach by directly combining CAN bus voltage data with current sensor inputs, eliminating the need for high-voltage wiring and post-processing, and ultimately enhancing the efficiency of certification testing.

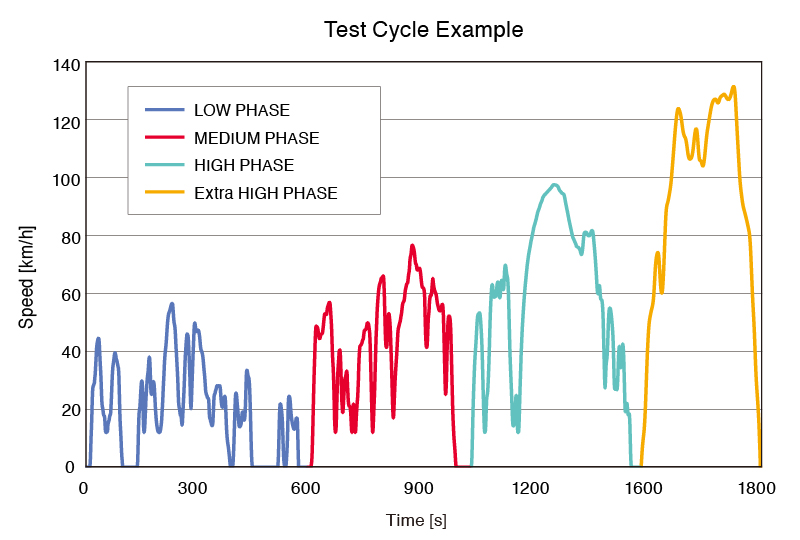

Fig. 1. Certification test: vehicle energy consumption and range test

The Role of Global Driving Cycles: WLTP, EPA (SAE J1634)

Certification tests, such as the WLTP (Worldwide Harmonized Light-duty vehicles Test Procedure) and the EPA driving cycle used primarily in the US (SAE J1634: Battery Electric Vehicle Energy Consumption and Range Test Procedure), are critical frameworks for assessing vehicle energy consumption and range. While each cycle features unique test conditions tailored to local environments, they all share the common goal of providing fair, comparable, and reliable vehicle performance data. This ensures that end users can accurately assess and compare vehicle efficiency across brands and regions. The reliability of these tests hinges on strict measurement requirements defined in the respective standards.

Fig. 2. WLTP test cycle

The Challenge of Voltage and Current Measurement in Vehicle Testing

Traditionally, obtaining voltage data required physically wiring into the vehicle’s high-voltage lines, leading to time-consuming and at times dangerous tasks:

- Time-consuming setup:

High-voltage wiring requires careful routing and implementation of protective measures. Furthermore, measuring current accurately in tight spaces has traditionally been challenging. Large clamp sensors can be difficult to handle and install, particularly in dense engine compartments or EV battery systems. - Safety hazards:

Misconnections or operational mistakes can damage vehicle batteries or, in extreme cases, cause an electric shock. - Post-processing burden:

Current and voltage are often logged separately, requiring added steps of data synchronization and power calculation.

Fig. 3. Power Analyzer PW4001 and AC/DC Current Probe CT6834

Test Breakthrough with the PW4001 and Compact High-Precision Current Sensors

Hioki’s PW4001 Power Analyzer introduces a breakthrough: the ability to directly acquire voltage data via CAN, process it with current data, and send this data to the test system via communication commands or XCP on Ethernet. This innovation delivers:

- Real-time power calculation:

No need to perform post-measurement power computations, it calculates power in real time from current sensor measurements and CAN-acquired voltage data. - Direct power data output:

The PW4001 sends already-processed power measurements to the test system, ready for certification. - Safe from high-voltage wiring:

Since voltage data is transmitted via CAN, the test engineer is not exposed to the vehicle’s HV power lines by having to physically tap into it.

Complementing this innovative functionality is Hioki’s lineup of compact, high-precision clamp-type current sensors, designed specifically for automotive testing. These sensors:

- Allow easy, one-handed installation in confined spaces

- Provide exceptional accuracy even for low currents

- Reduce setup frustration and speed up the preparation process for test engineers through easy-to-use designs

Together with these sensors, the PW4001 offers a seamless, efficient, and user-friendly measurement experience.

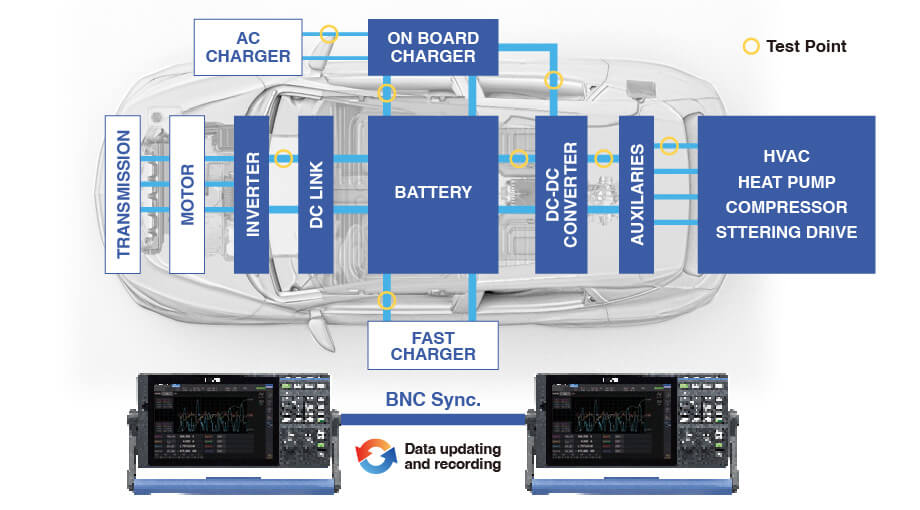

Fig. 4. Vehicle power consumption test: CAN-bus voltage data and current sensor data

Practical Benefits and Cost Savings

Whether it be cost reductions or easier testing, each of these practical benefits provide real value to the test engineer in addition to providing reliable test results.

- Improved safety

- Reduced setup time

- Ease of sensor installation

- No post-processing required

- Simplified test setup

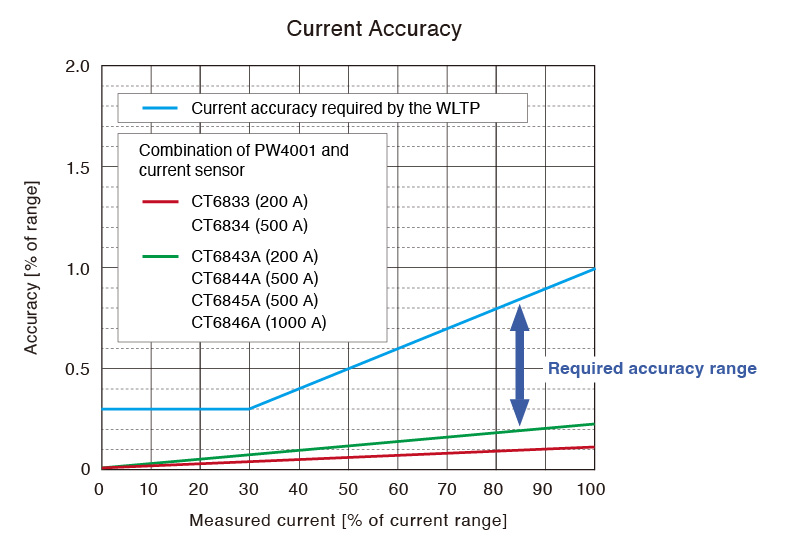

Meeting Stringent Accuracy Standards: Operating Temperature Range from -20°C to +50°C

Even with this simplified setup, Hioki’s PW4001 and current sensors do not compromise on accuracy. They meet or exceed the accuracy requirements defined in WLTP and SAE J1634 including:

- Voltage accuracy: ± 0.3% of range or ±1 % of reading (both WLTP and SAE J1634)

- Current accuracy: ± 0.3% of range or ±1 % of reading (both WLTP and SAE J1634)

- Energy(power integration) accuracy: aligned with IEC 62053-21 standards (WLTP)

Whether measuring 400 V or 800 V vehicle architectures, the PW4001 ensures compliance, providing certification engineers with the confidence they need.

Fig. 5. Combination accuracy meeting WLTP and SAE J1634 requirements

Scalable Multi-Point Measurements

Understanding vehicle power consumption in detail requires expanding the number of measurement points. The PW4001 supports this need through its synchronization capability: up to 8 PW4001 units can be linked so that their measurements’ start, stop, and recording intervals are precisely synchronized. This enables a comprehensive evaluation of complex automotive electrical systems without compromising time alignment or data integrity.

Fig. 6. Scalable measurement up to 32 channels

Take Your Testing to the Next Level

Hioki’s PW4001 transforms automotive certification testing to be safer and more efficient, while remaining compliant to standards. By combining CAN voltage with highly accurate and compact current sensing, the PW4001 reduces setup time, eliminates safety hazards, and delivers ready-to-use power data, helping certification teams save time, costs, and effort. It’s not just a measurement tool; it’s a complete solution for the future of EV and hybrid vehicle testing.

For details, please refer to the following materials.

- Achieving Accurate EV Range and Energy Consumption Testing Under WLTP Standards

- Utilizing Vehicle On-Board CAN Data to Simplify WLTP Energy Consumption Evaluations

For detailed product information, please visit our website. For a demonstration or consultation on a specific application, please contact us.