Measuring Welding Resistance to Improve the Performance of Lithium-ion Batteries

Focusing on weld quality to boost the performance of xEV batteries

Helping improve quality with accurate and high-speed super-low-resistance measurement

Featured customer

Company J is an Asia-focused automobile manufacturer that's expanding to the global market. The company began developing and selling hybrid electric vehicles (HEVs) at an early stage. More recently, it's been focusing on developing electric vehicles (EVs) in line with the global shift towards electrification.

Background

Addressing the need to accurately and non-destructively assess the quality of welds in batteries earlier in the manufacturing process.

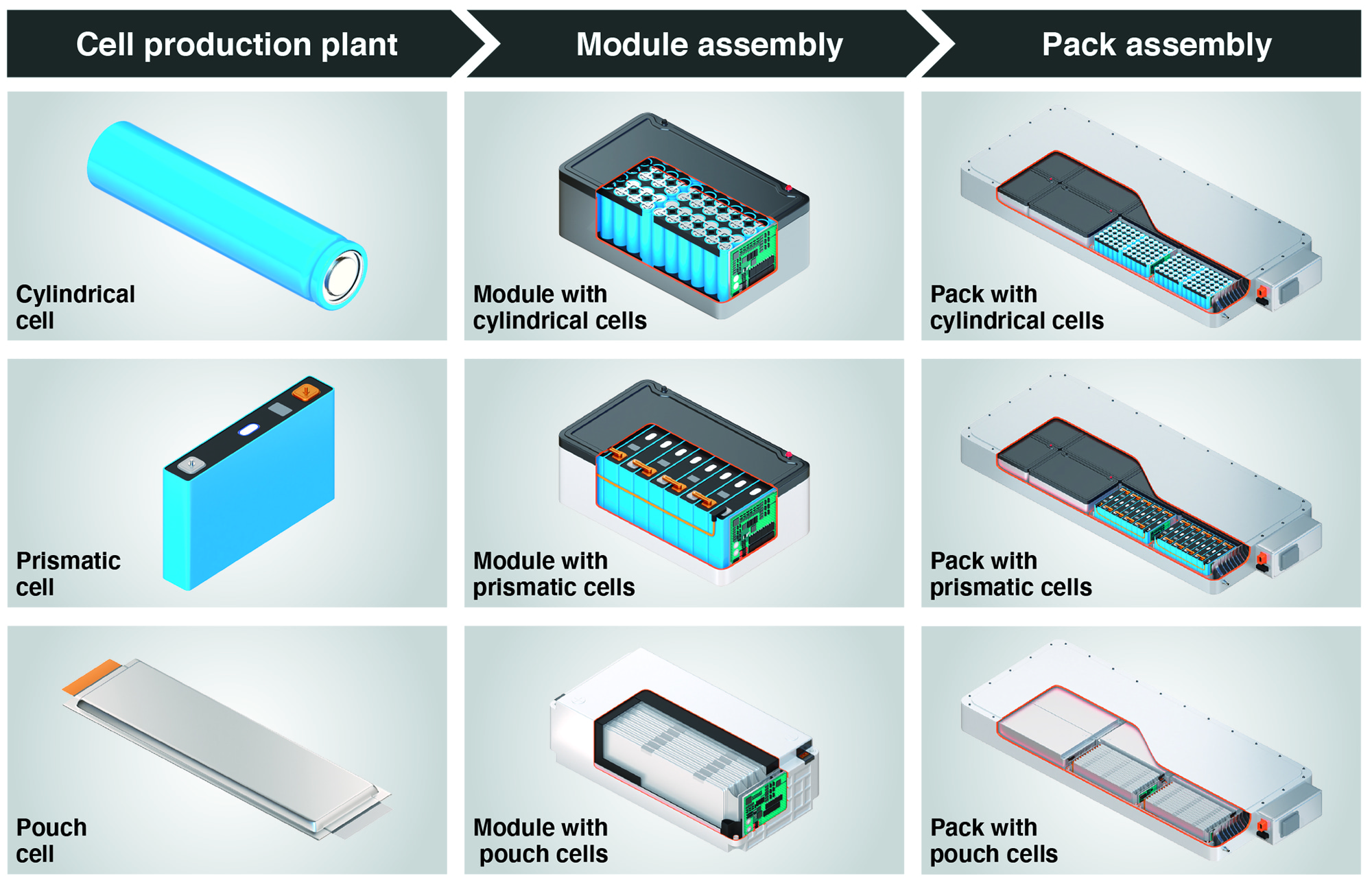

Amid rising global awareness of the need to achieve the United Nations Sustainable Development Goals (SDGs), many countries and companies have been working to realize a carbon-neutral, decarbonized society. In the context of that effort, the forecasted move towards renewable energy and EVs is likely to fuel further market adoption and utilization of rechargeable batteries (secondary cells). Lithium-ion batteries are particularly likely to see significant demand growth as EVs gain widespread adoption.

Demand for lithium-ion batteries, which offer long service life and a high level of safety, is growing amid expectations for higher-power, larger, significantly less expensive batteries. As adoption of batteries spreads to a wide range of fields, customers have sought additional improvements in lithium-ion battery performance.

As an automaker that's focusing on EV development as it looks towards the global market, Company J has dedicated many development hours to improving the performance of the lithium-ion battery packs used in EVs. Having made repeated across-the-board improvements to boost battery pack performance, the company has shifted its focus in recent years to improving the quality of welds in batteries. Welds are used in a variety of joining steps throughout the battery cell and battery pack manufacturing process. Defects in the quality of welds that involve electrical circuits are particularly critical insofar as they can prevent the battery cell and battery pack from realizing its full performance.

To date, Company J has monitored welder operation and eliminated defective products using visual inspections and image-matching inspections of welds. However, destructive testing of welds as part of sampling inspections has demonstrated the low reliability of pass-fail judgments by revealing that products thought to be non-defective were in fact defective and that products eliminated because they were thought to be defective were in fact non-defective. By allowing them to flow through to subsequent production processes, delayed detection of defective products has a significant impact on battery manufacturing costs. In the worst case, defective products could be shipped to the market. Company J had been studying how it could accurately and non-destructively assess battery quality at an earlier stage of the manufacturing process.

Module with prismatic cells

Module with prismatic cells Welds

Welds

Key considerations that led the customer to choose Hioki

High praise for a dedicated tester that can quickly and accurately measure super-low resistance that would be undetectable with a DMM

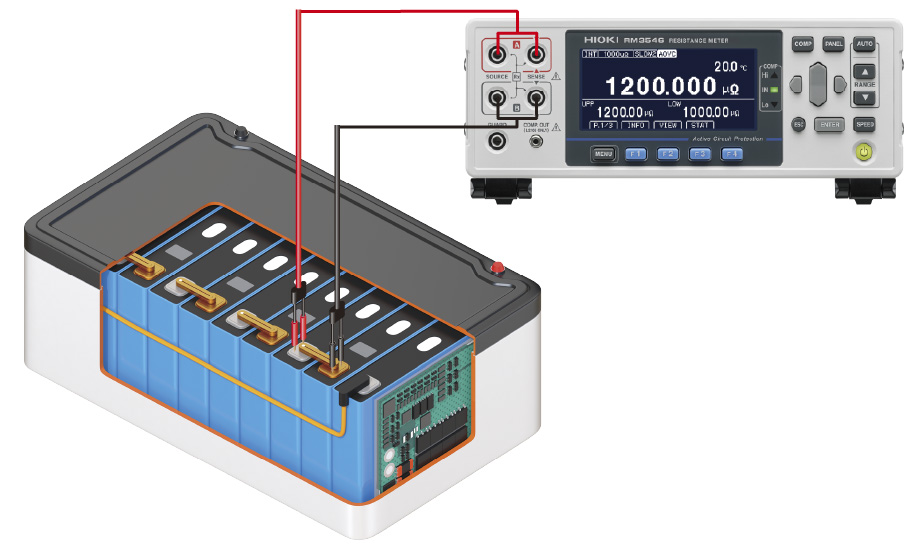

In its effort to quantify aspects of weld quality that are not readily observable and to do so in a highly reproducible manner, Company J augmented conventional quality inspections with a focus on electrical weld resistance measurement. High resistance values can cause heating during the charging and discharging of lithium-ion batteries, which potentially can lead to fire as well as degraded performance. The company incorporated measurements of weld resistance into the manufacturing process from the dual standpoints of battery performance and safety.

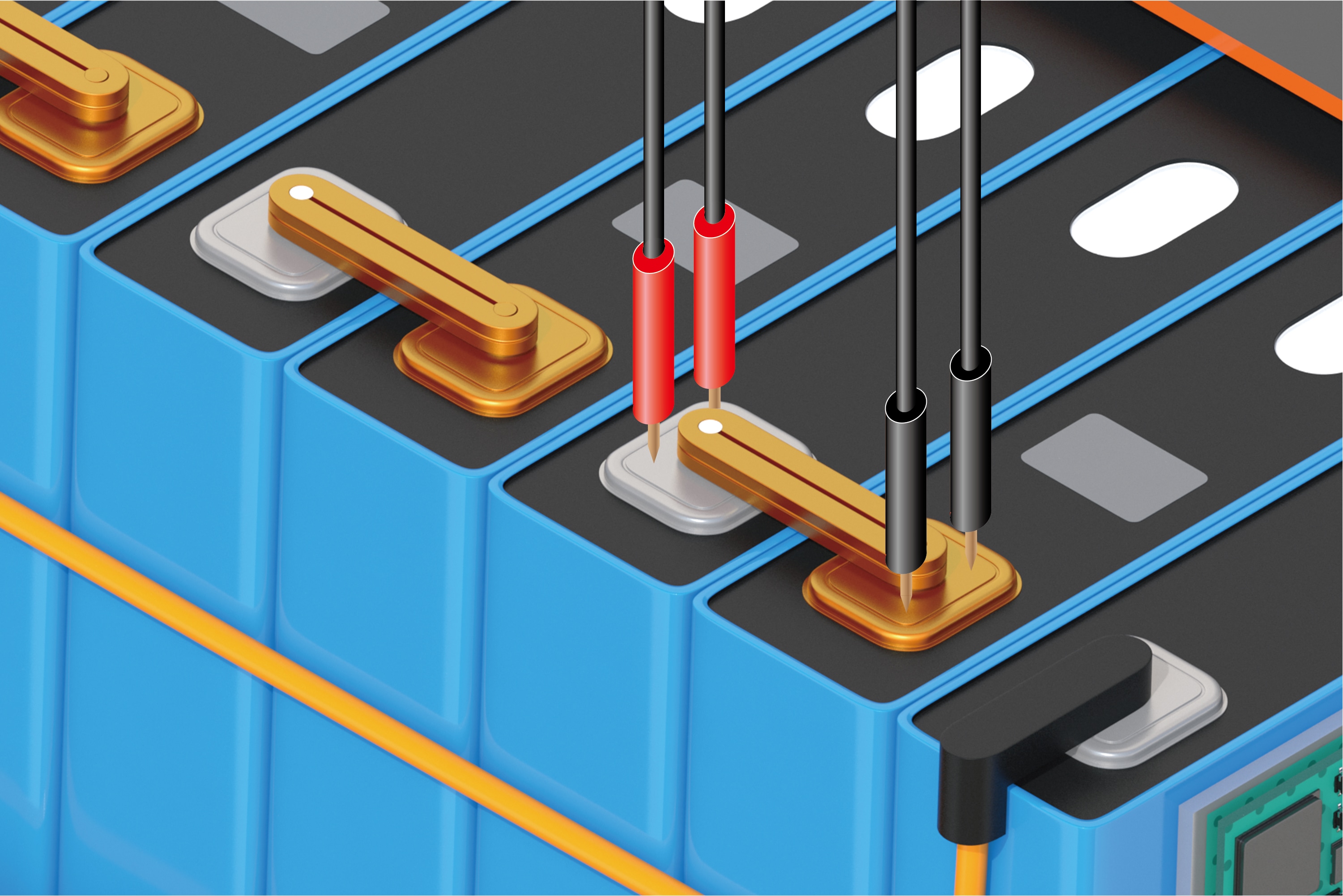

However, time spent on resistance measurement must be minimized due to the need to manufacture lithium-ion batteries as quickly and in as great a quantity as possible to accommodate rising global demand. Moreover, unlike electronic components, where the trend is towards miniaturization, automotive batteries, busbars, and related parts are only growing larger. The inverse trend for resistance values is to decline. Manufacturers face extreme challenges as they look to accurately measure extremely small resistance values on the order of microohms in large components.

Initially, Company J measured weld resistance using the same digital multimeters (DMMs) it uses in voltage measurement processes. However, after realizing that such instruments' resistance measurement capabilities were not sufficient to accurately detect the super-low resistance of welds, the company began considering whether to purchase dedicated instruments specifically for use in super-low-resistance measurement. After gathering information from a number of vendors, the automaker chose the Hioki Resistance Meter RM3546.

The RM3546 incorporates expertise and technology for accurately measuring electrical resistance as accumulated by Hioki as it developed numerous resistance meters and amassed a track record of success in a variety of industries. The product's ability to measure resistance across a wide range, from 1 nΩ to 1200 MΩ, satisfied Company J's requirements, as did its particular strengths in measuring super-low resistance (ultralow resistance).

Measurement example: Resistance Meter RM3546

Measurement example: Resistance Meter RM3546

Contact area

Contact area

Battery packs that consist of multiple connected battery cells generate large voltages.

When the resistance of battery pack busbar welds is measured, these large voltages can cause instrument damage, inviting downtime on volume production lines. RM3546 prevents downtime through its protection function that guards against this overvoltage input.

ACP Function (Active Circuit Protection)

ACP Function (Active Circuit Protection)

Benefits

Automatic, super-low resistance measurement of welds with accuracy, safety, and speed

Company J built a system capable of automatically measuring super-low resistance accurately, safely, and quickly in the battery pack busbar weld inspection process by embedding the Resistance Meter RM3546 into the Flying Probe Tester FA1240-61. In the measurement of battery pack busbar welds, a difference of just 1 mm in the positions at which probes make measurements can cause measured values to change by dozens of microohms. In this way, positioning precision is critical, and Hioki's advanced probing technology makes possible automatic, accurate resistance measurement.

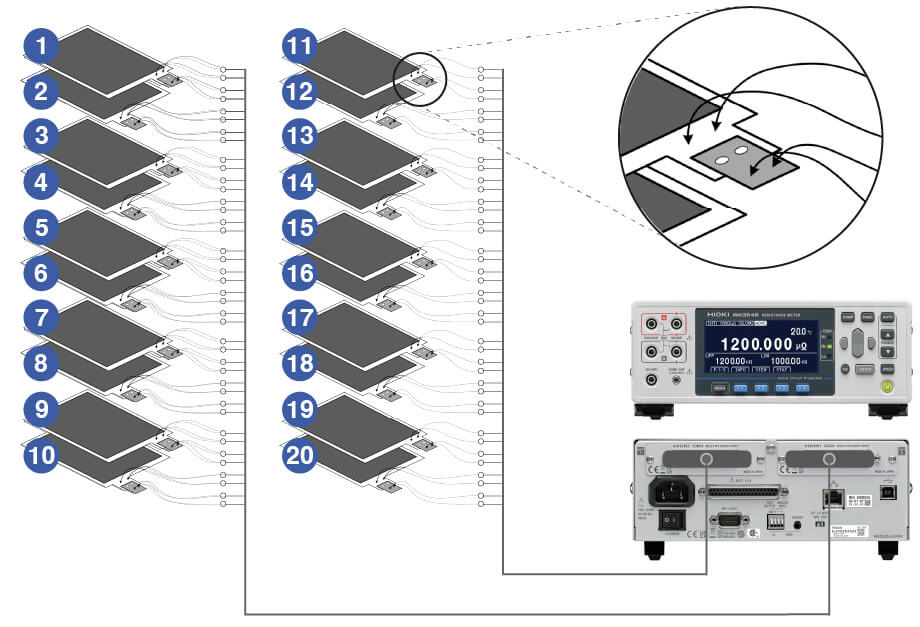

In other inspection processes, Company J had implemented high-speed, multichannel testing to reduce weld resistance measurement times for components like electrode sheets and tab leads inside battery cells. The Z3003 module, which can be installed in a slot in the RM3546, allows a single instrument to switch among up to 20 channels at high speed. As a result, the company can test multiple products being transported on a single tray at once, allowing it to improve performance across the production line at low cost and without expanding the footprint of installed equipment.

Installing the Multiplexer Unit Z3003 to the RM3546

Installing the Multiplexer Unit Z3003 to the RM3546

Multipoint measurement of 20 locations when two Z3003 modules are mounted (for 4-terminal measurement)

Multipoint measurement of 20 locations when two Z3003 modules are mounted (for 4-terminal measurement)

Thanks to this automatic inspection system, which combines the RM3546 with the FA1240-61 and Z3003, Company J can accurately quantify weld quality in a way that previously was only possible through destructive testing. The coordinator responsible for the purchase decision expressed confidence that the ability to perform super-low-resistance measurement automatically, at volume, and at speed has helped improve the performance and quality of lithium-ion batteries used in EVs.

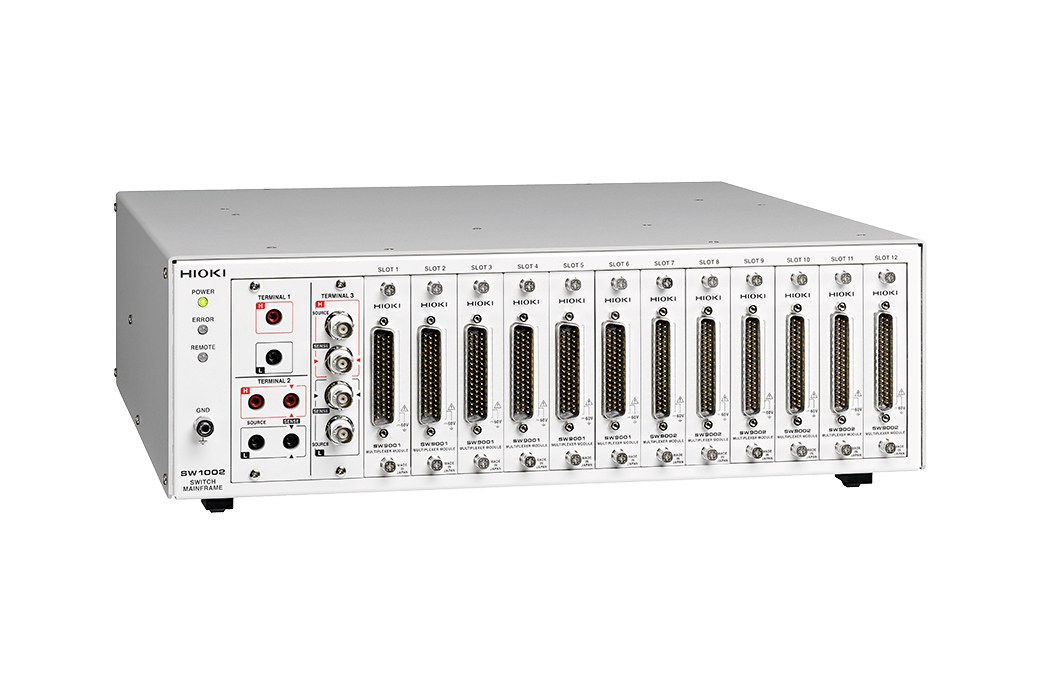

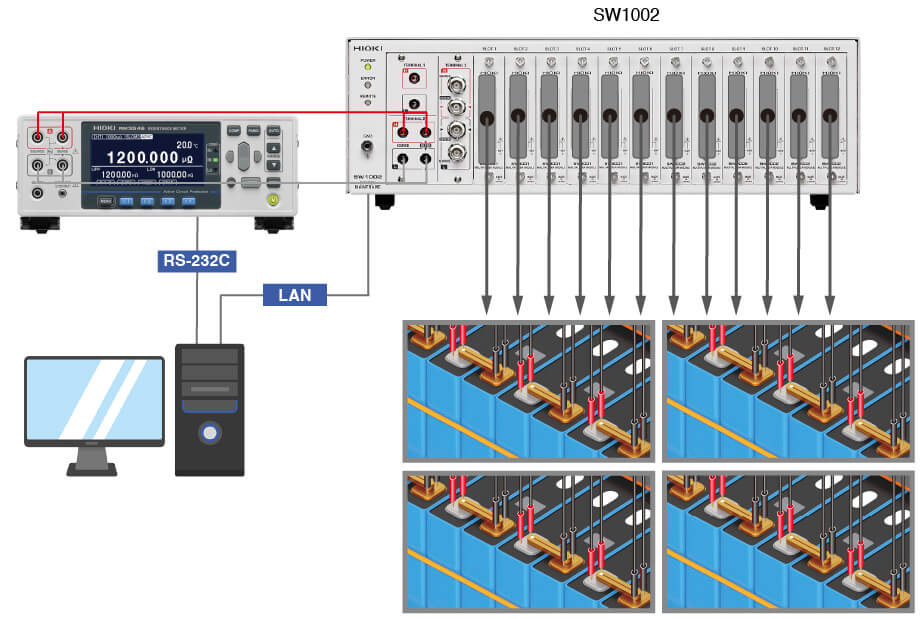

Looking towards the future, Company J is considering purchasing the Switch Mainframe SW1002 and Multiplexer Module SW9001, which can be added as peripherals to increase the number of measurement channels to a maximum of 132 ch, in an effort to further speed inspection processes and enhance safety.

Combination Example of Switch Mainframe SW1002 and RM3546

Combination Example of Switch Mainframe SW1002 and RM3546

Company J is also considering the BT3560 Battery Tester series, which can accommodate voltages of up to 1000 V.

Going forwards, the automaker plans to continue to enlist the cooperation of Hioki, which offers an extensive range of options, to pursue R&D with the goal of improving the performance of lithium-ion batteries.