Quickly Check the Power Quality

Enabling maintenance management and fast troubleshooting with centralized management and instant review of power quality

Featured customer

Company G, which has facilities in the Southeast Asian nation E, operates three businesses: generating, transmitting, and supplying power. As a government-run company, it enjoys a robust financial base, and it supplies power to most of country E, from urban areas to agricultural villages.

Background

Accurately measuring and quickly checking power quality to facilitate fast troubleshooting

The supply of power is not keeping pace with growing demand in country E, which is located in Southeast Asia, despite steady progress in building out infrastructure in recent years. Problems such as power quality issues caused by equipment occasionally prompt unease on the part of customers.

As an enterprise that generates, transmits, and supplies power in country E, company G was interested in accurately and quickly assessing facts and conditions when problems occur so that it could quickly resolve them. However, the company found that the equipment it was using to monitor power quality, which had been purchased from another manufacturer, wasn’t enabling it to pinpoint the causes of problems or maintain and manage its businesses day in and day out in a satisfactory manner.

For example, personnel had to travel to various sites in country E where monitoring equipment was located in order to obtain measurement results because power quality data was stored on that equipment. Further, although analytical software can be used to process measurement data from a variety of perspectives, company G felt constrained in its ability to do so due to the inability to customize its software to suit its unique requirements.

The company had other complaints as well, including clamp-on sensors that had to be gripped with considerable strength in order to affix them to wires, making the measurement process unnecessarily labor-intensive, and poor timing precision despite connecting monitoring systems to a LAN so that the entire network could be synchronized to the same time using NTP.

Key considerations that led the customer to choose Hioki

Making a decision based on remote monitoring capability, high measurement precision, and ease of use

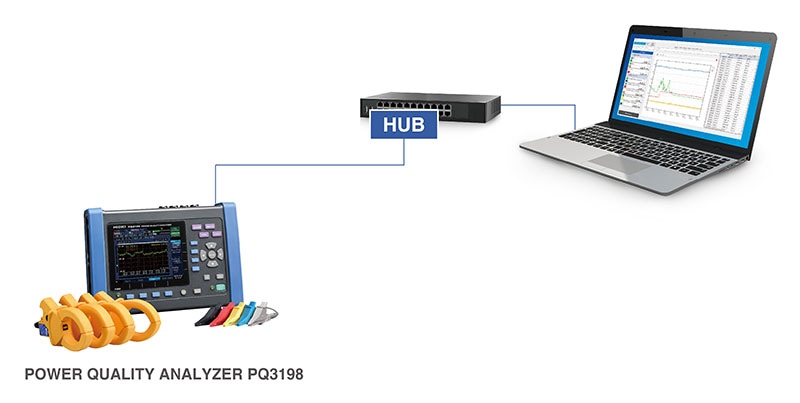

A distributor in country E proposed the Power Quality Analyzer PQ3198 and the dedicated software for the product just as company G was considering replacing its power quality monitoring equipment. It was the remote monitoring capability that attracted the company’s attention to the proposal.

Other manufacturers’ products didn’t offer the ability to connect instruments and computers nationwide with a LAN so that measurement data could be acquired, and equipment operated, remotely from the desktop.

To compare the measurement precision of the proposed system with competing products, the company applied a 400 V current from a calibration device. Whereas the competing products indicated a measurement result of 398 V, the PQ3198 accurately measured 400 V. Company G was impressed by this high level of precision.

Additionally, the alligator clip in which the PQ3198’s voltage cords terminate can be replaced with a magnetic adapter when it’s difficult to connect the instrument to metal terminals. Hioki’s integrated approach, which allows it to supply such parts, was also a factor in the decision to choose Hioki’s solution, along with the resulting adaptability and capability.

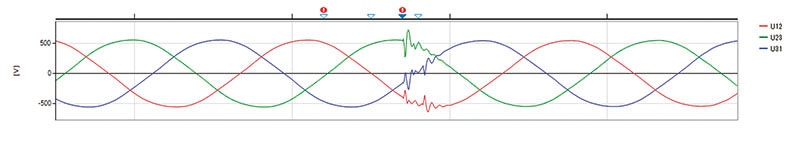

In addition, for transient voltage measurements, the PQ3198 offers a wide range of low- to high-voltage measurements in a single range, as well as a wide frequency range of up to 700 kHz with a 2 MHz sampling frequency.

The ability to acquire data in a more fine-grained manner than competing products and to detect even minuscule transient voltages aligned perfectly with company G’s requirements.

Magnetic Adapter

Magnetic Adapter AC/DC Current Sensor

AC/DC Current Sensor

The company also had high praise for an extensive range of convenient functions that are not available elsewhere, including functionality for instantaneously assessing whether the correct wiring is being used based on current and voltage vector diagrams and for ascertaining direct current (DC) to alternating current (AC) conversion efficiency. For these reasons, company G decided to purchase the PQ3198 and PQ ONE.

Benefits

Realizing fast troubleshooting thanks to centralized management and instant review of measurement data

Company G gained the ability to collect measurement data from business sites via a LAN network despite the size of country E, allowing it to put in place the structures needed to centrally manage data and instantly review data from remote locations. Since technicians can immediately ascertain the nature of the phenomena in question and its cause when a problem occurs, they can immediately get to work on repairs and improvements. As a result, issues can be resolved quickly. The company has also gained the ability to respond quickly to inquiries from customers about problems.

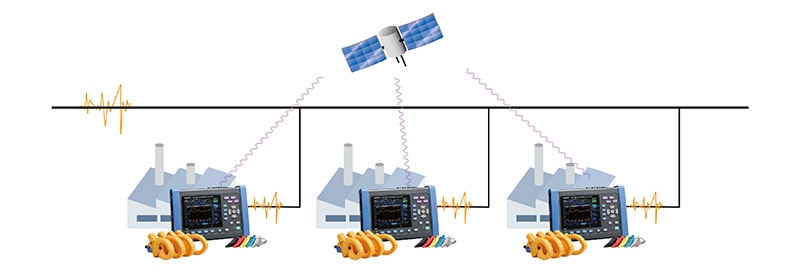

Since it wanted to measure power quality at different locations at exactly the same time, company G wished to add GPS capability to each instrument so that measurement times could be synchronized. Hioki proposed its GPS Box to fulfill the requirement. The GPS Box allows each instrument's internal clock to be corrected based on UTC standard time. That synchronization makes it possible to maintain simultaneity when analyzing data measured by multiple instruments. The unit is convenient to use since it works both indoors and outdoors.

GPS time synchronization

GPS time synchronization

Additionally, company G changed the specifications of its analytical software so that the power range used to analyze voltage and current together is no longer predetermined, allowing personnel to select kilowatts and gigawatts in addition to megawatts.

By installing the PQ3198 and PQ ONE at 16 locations around country E, company G was able to resolve all of its previous complaints involving power quality measurement.

The company plans to expand the scope of the project by adding instruments at more locations, including about 200 business sites. Finally, the company plans to work with Hioki to resolve issues with malfunctioning distribution panels, which it recently identified as a problem.