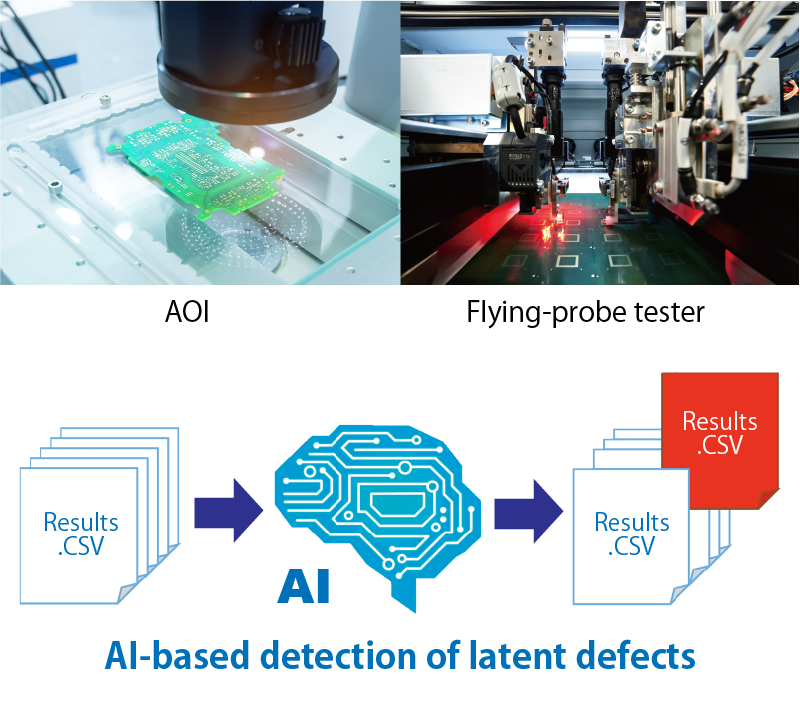

AI analyzes the board inspection data of the flying checker and detects latent defects that are difficult to find

Limits of Circuit Board Optical Inspection Systems and Circuit Board Electrical Testing

Although they can detect circuit defects, automatic optical inspection (AOI) systems are unable to guarantee electrical conductivity or test inside through-holes. Additionally, a full and complete testing regimen must include tests of individual inner layers.

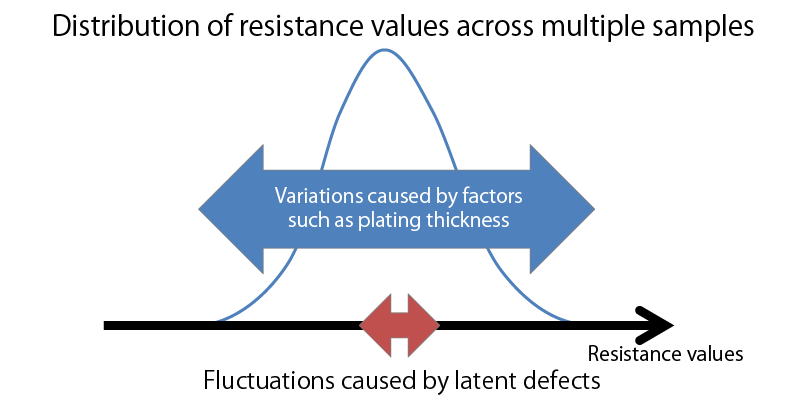

While flying-probe systems can electrically test capacitors and resistance values on nets, there are defects that go undetected within the range defined by user-specified threshold values.

The Process Analyzer Pro UA1801 uses AI-based “teacher-less learning” capability to identify singularities within ranges of threshold values in flying-probe test data, allowing it to detect latent defects.

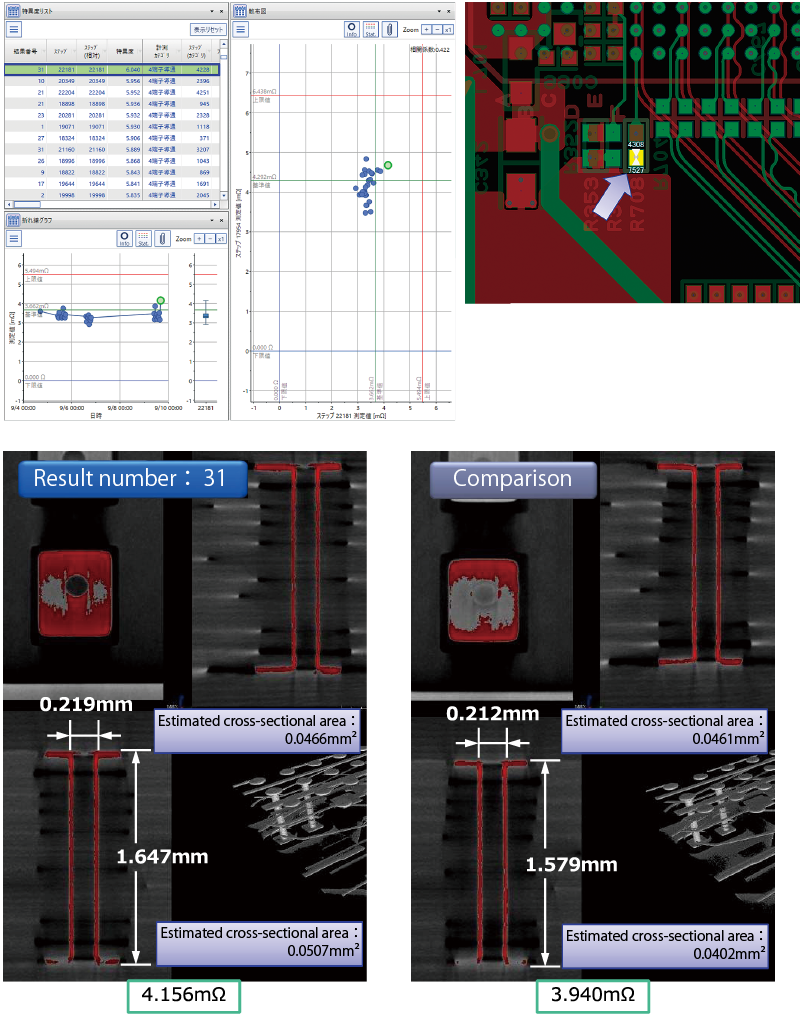

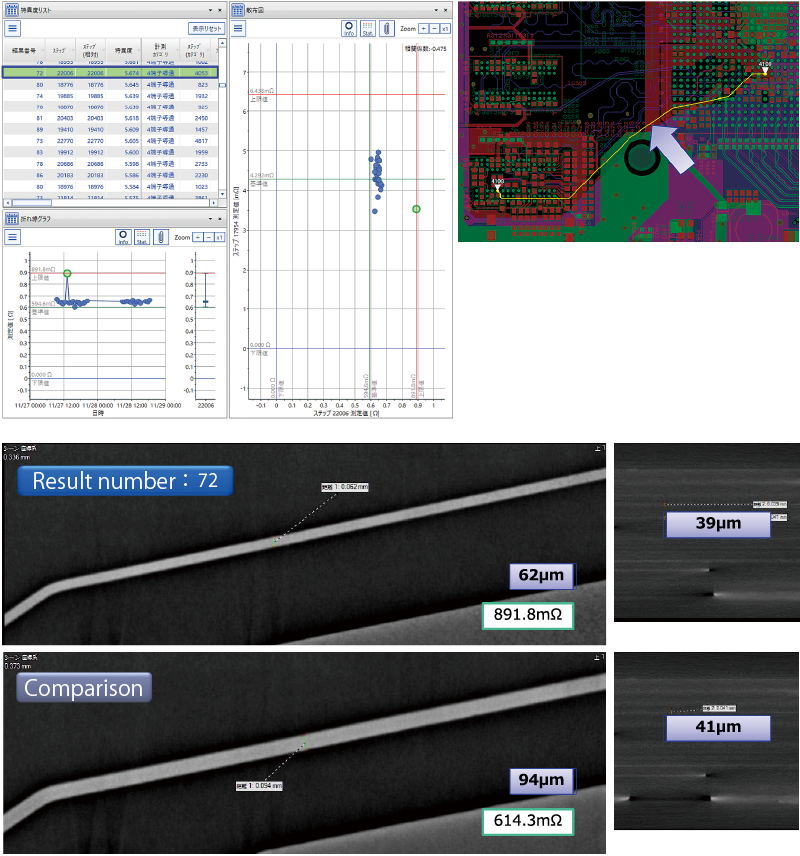

Detection Example 1: Through-hole Anomaly

An analysis of X-ray images of through-holes from one board on which an anomaly was detected and another on which no anomalies were found revealed differences in thickness and volume.

Example Detection 2: Tapering of an Inner-layer Pattern

An analysis of X-ray images of internal patterns from one board on which an anomaly was found and another on which no anomalies were found revealed pattern tapering.

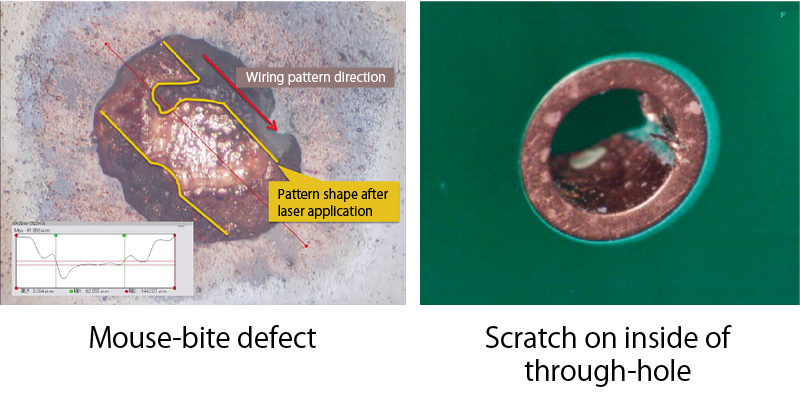

Detection of Imitated Defects

AI-based learning and detection of resistance value distributions were able to detect an artificially created “mouse bite” defect as well as a scratch on the inside of a through-hole.

AI-based Detection of Resistance Value Changes Caused by Defects