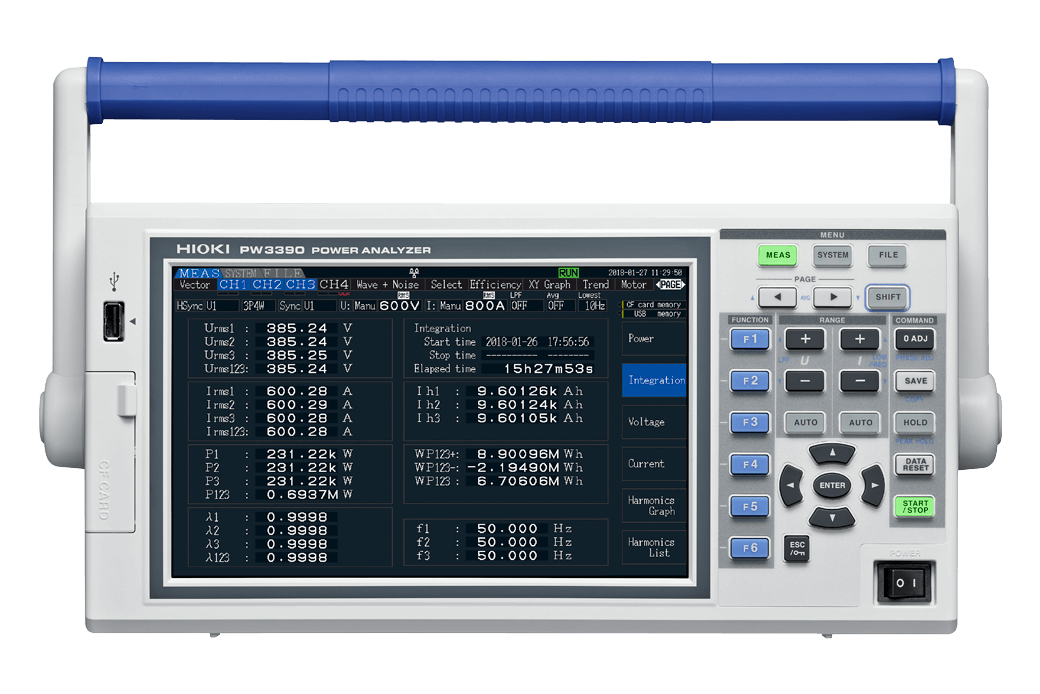

POWER ANALYZER PW3390

DC, 0.5 Hz to 200 kHz, 3-phase 4-wire, High Precision Power Analyzer for Motor and Inverter Efficiency Analysis

To Be Upgraded

Hioki benchtop power meters and power analyzers are best in class power measuring instruments for measuring single to three-phase lines with a high degree of precision and accuracy. The PW3390 is a high-precision, broad-range power analyzer for measuring electrical power from DC to inverter frequencies, providing four input channels to support single- and three-phase inverter motor systems up to 4000 A AC/DC with superior accuracy.

High-accuracy, high-speed calculation of transient-state power in 50 ms; harmonic analysis; display of instantaneous waveforms; noise analysis; and simultaneous parallel calculation of all parameters, including efficiency loss

Delivering High Accuracy and Mobility in One Single Device

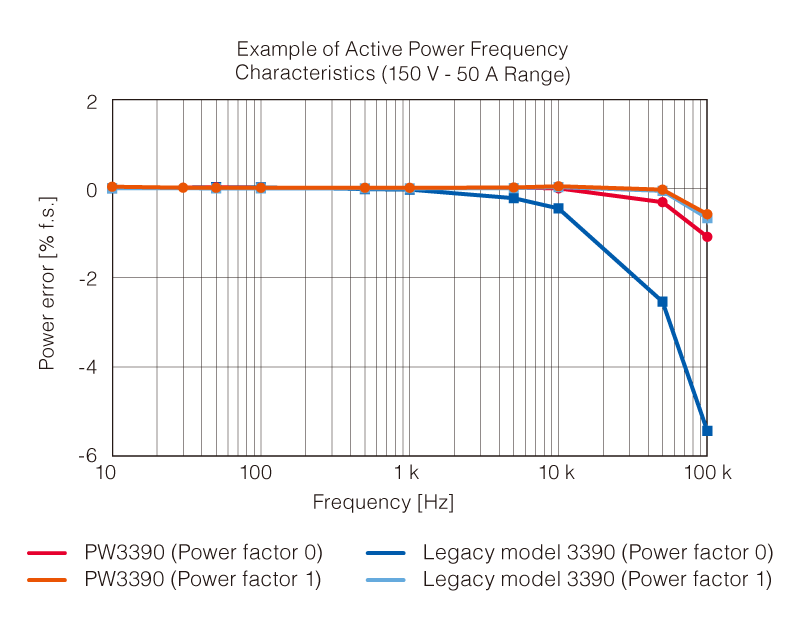

The Hioki PW3390 Power Analyzer offers ±0.04% ±0.05% f.s. power accuracy, the top of its class. With a 200kHz measurement bandwidth and flat amplitude and phase characteristics up to high frequencies, as well as a powerful phase shift correction function that maximizes the power of its original current sensors, the PW3390 can now be utilized by researchers and developers to high frequency, low power factor power with absolutely accuracy. Apply the PW3390 and Hioki current sensors to power conversion efficiency evaluations and the analysis and harmonic studies of EV and HEV inverter motors.

Key Features

- ±0.04% basic power accuracy, among the best in its class

- 200 kHz measurement band with flat amplitude and phase accuracy that extend to high frequencies

- Remarkably small and light footprint, enabling high-accuracy measurement to be easily carried out even in the field

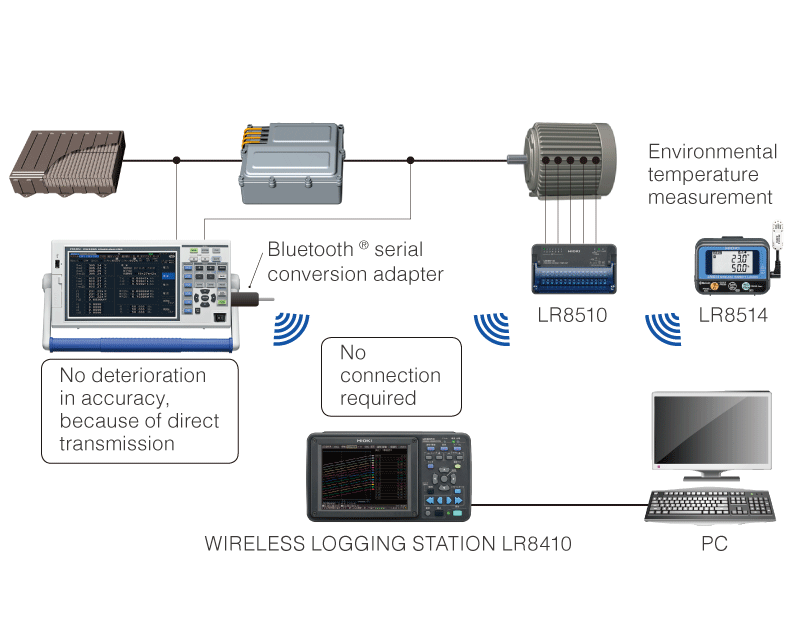

- Send measured values to Hioki data loggers using a Bluetooth® wireless technology compatible adapter (LR8410 Link-compatible products)

- Simultaneous measurement of multiple circuits and ability to acquire synchronized data using up to 8 devices (for 32 channels)

- Simple power measurement using clamp-on current sensors

- Measurement of current and power inputs and outputs as part of the new WLTP fuel efficiency international standard

- Earning Japan Calibration Service System (JCSS) Certification for DC Power Measurement. (*1)

- *1: JCSS is standard that is satisfy the requirements of the ISO/IEC 17025 international standard.

Learn more

Model No. (Order Code)

| PW3390-01 | |

|---|---|

| PW3390-02 | D/A output |

| PW3390-03 | D/A output, motor analysis |

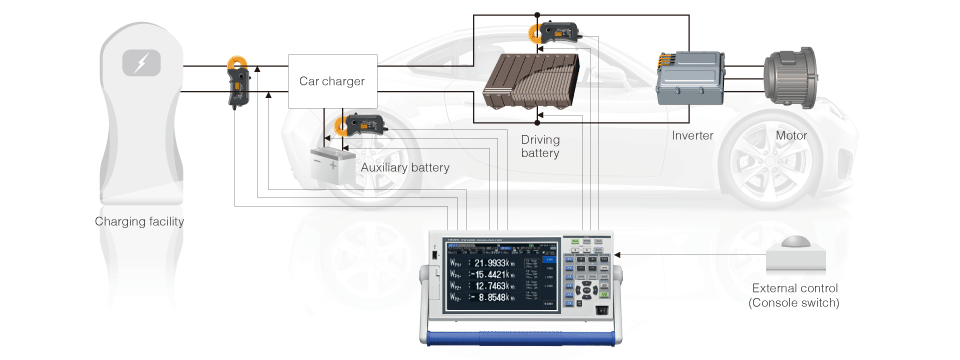

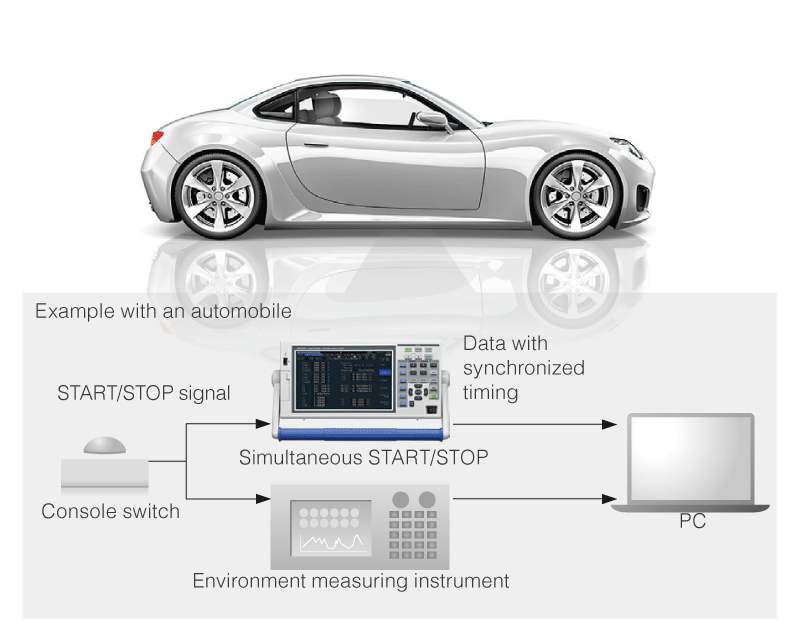

Test Automobile Fuel Economy

Using the Hioki PW3390 to Evaluate Vehicle Fuel Consumption Performance according to the Worldwide Harmonized Light vehicles Test Procedure (WLTP)

The Hioki PW3390 Power Analyzer is extremely effective in evaluating the fuel performance of automobiles, including in accordance with the Worldwide Harmonized Light vehicles Test Procedure (WLTP). Pair with Hioki high accuracy current clamp sensors to achieve high accuracy measurements even within hot engine compartments.

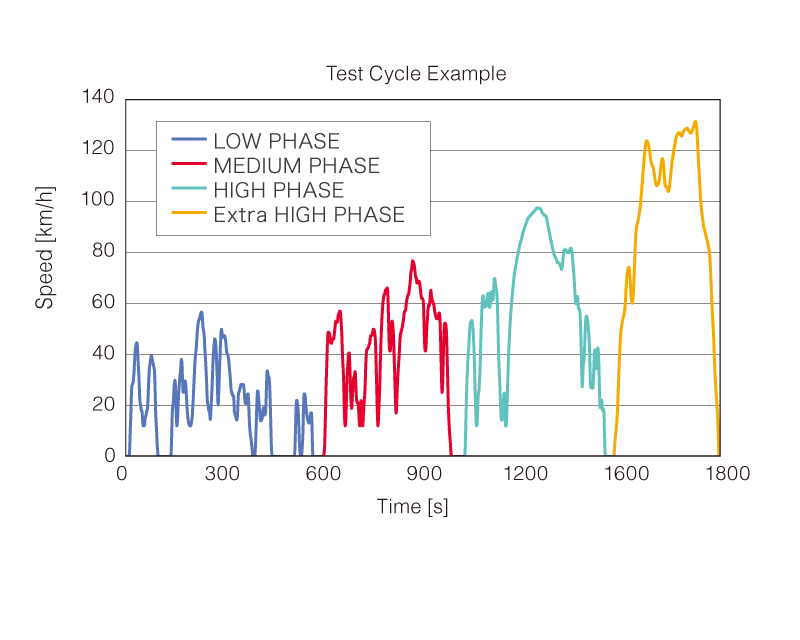

Evaluate WLTC Mode Performance - A New Fuel Economy Standard

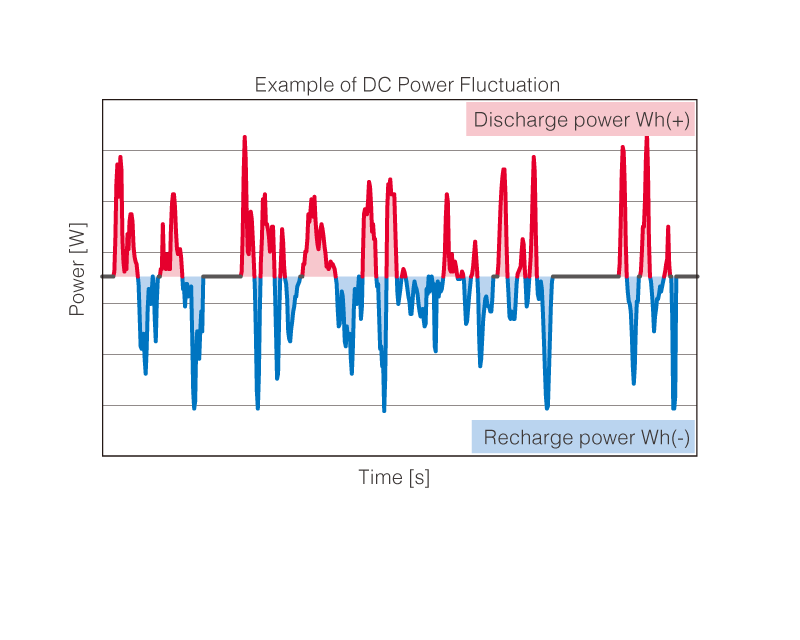

Taking fuel economy measurements that comply with WLTP standards requires the precise measurement of current integration and power integration for the recharging/discharging of each battery in the system. High accuracy clamp current sensors, the excellent DC accuracy of the PW3390, and the ability to integrate current and power at 50 ms intervals are extremely effective in meeting this application. Furthermore, the operating temperature range of the PW3390 has now been extended to reach −10°C, enabling the WLTP measurement in −7°C environments.

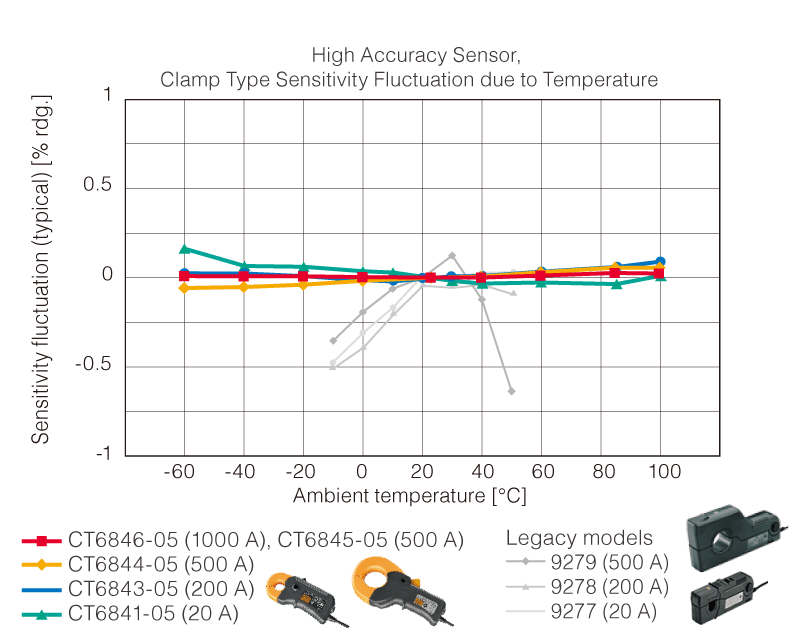

Optimal Current Sensors for Automotive Testing

Easily connect high accuracy clamp-type sensors without cutting the cables. Sensors operate over a temperature range of -40°C to 85°C (-40°F to 185°F), characteristics that enable highly accurate measurements even inside the engine room of a car.

Current and Power Integration Function by Polarity

DC integration measurement integrates the recharging power and discharging power by polarity for every sample at 500 kS/s, and measures positive-direction power magnitude, negative-direction power magnitude, and the sum of positive- and negative-direction power magnitude during the integration period. Accurate measurement of recharging power and discharging power is possible even if there is rapid repetition of battery recharging/discharging.

Link to Peripheral Devices via External Control

Use external control terminals to START/STOP integration and capture screen shots. This makes it easy to control operations from console switches and link to the timing of other instruments when measuring the performance of an actual automobile.

Proper Accuracy and Bandwidth to Precisely Measure Inverter Output

Complete Pursuit of Measurement Accuracy and High Frequency Characteristics

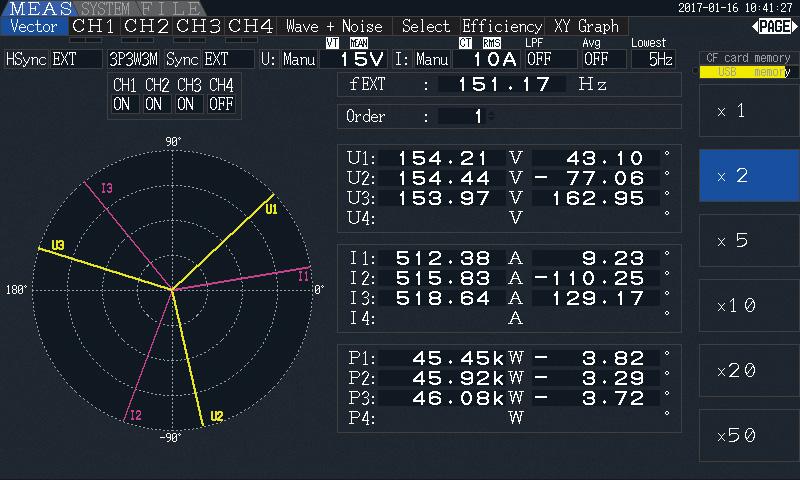

The PW3390 delivers 4 input channels and ±0.04% basic accuracy for power - the top instrument in its class. Achieve more precise measurements of the power and efficiency of high efficiency equipment used in power electronics. Further, a 200 kHz measurement band and flat amplitude and phase characteristics up to high frequencies enable the precise measurement of power at top frequency levels and low power factor.

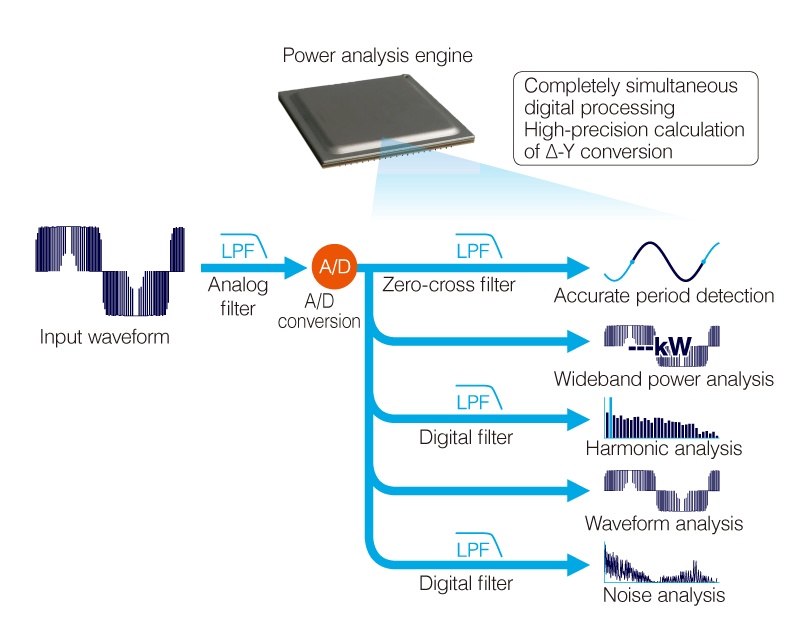

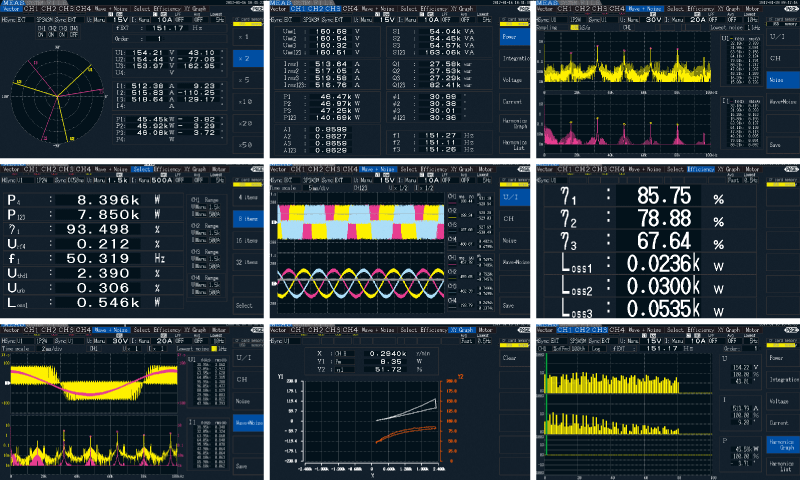

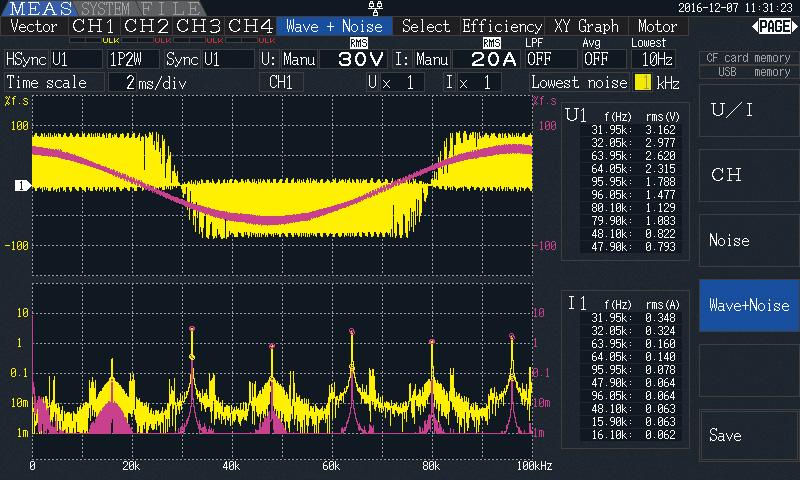

Power Analysis Engine That Achieves High-Speed Simultaneous Calculation on 5 Systems

Precisely capture input waveforms with 500 kS/s high-speed sampling and a high resolution 16-bit A/D converter. The power analysis engine performs independent digital processing for 5 systems: period detection, wideband power analysis, harmonic analysis, waveform analysis, and noise analysis. High-speed simultaneous calculation processing enables both precise measurements and a 50 ms data refresh rate.

Hioki PW3390 Power Analyzer: Expand Measurement Possibilities with a Rich Lineup of Current Sensors

Hioki designs and manufactures current transducers with superior precision, high accuracy clamp sensors that provide ultimate measurement convenience, and flexible current sensors that support up to 6000 A of current for measuring power with the Hioki PW3390 Power Analyzer. With this diverse lineup of current sensors, customers can easily meet applications such as testing the secondary side of inverters to measuring large currents from commercial power lines. The superior performance of the PW3390 is housed in a compact footprint that enables researchers and developers to easily and accurately analyze power and power-related parameters including voltage, current, power, harmonics, signal waveforms as well as power efficiency.

Current Sensors for the Thorough Pursuit of High Accuracy

-High Accuracy Sensor Pass-Through Type

Pass-through type with high accuracy and a wide measurement range. Conduct extremely accurate measurements of large currents to a maximum of 2000 A over a wide operating temperature range.

-High Accuracy Sensor Clamp Type

Clamp for quick and easy connections.

With a diverse lineup ranging from compact sensors that can be easily installed even in complicated wiring or narrow/tight spaces, to those capable of detecting large currents up to 1000 A across a wide operating temperature range, we ensure highly accurate measurements.

-High Accuracy Sensor Direct Wire Type

Newly developed DCCT method delivers expansive measurement range and superior measurement accuracy at a rating of 50 A.

Click to see lineup of high-accuracy pass-through/clamp type sensors and direct connection types

Built-in Current Sensor Phase Shift Function. Achieve Superior Accuracy for High-Frequency, Low Power Factor Power

Equipped with new virtual oversampling technology. Achieve phase shift equivalent to 200 MS/s while maintaining a high speed of 500 kS/s, as well as a high resolution of 16 bits. Set and correct the phase error of the current sensor at a resolution of 0.01°. Use of the phase shift function results in a dramatic reduction of measurement error. This allows the measurement of high-frequency, low-power factor power included in the switching frequency of inverter output, which is difficult to measure with conventional equipment.

* Virtual oversampling: Technology that uses a sampling frequency several hundred times higher than the actual sampling frequency to perform virtual deskewing.

In the Laboratory or in the Field

Take Highly Accurate Measurements Even in Tough Temperature Conditions

Severe temperature environments, such as engine rooms with intense temperature changes and constant temperature rooms, can hinder high accuracy measurements.

Hioki provides a lineup of high-accuracy pass-through-type and high-accuracy clamp-type current sensors with excellent temperature characteristics and wide operating temperature ranges, as well as compact size sensors that can be easily installed in complicated wiring and narrow/tight spaces.

The PW3390 can operate from a low temperature environment of −10°C to a high temperature of 40°C, allowing you to take it to measure in various environments.

Click to see lineup of high accuracy pass-through/clamp type sensors

Achieve High Accuracy Measurement Even in the Field

Dramatically compact and light-weight form factor achieved by concentrating the calculation functions in the power analysis engine. Highly accurate measurements normally achieved in the laboratory are now also possible in the field.

Max. 6000 A Measurement on 50 Hz/60 Hz Lines

The CT7040 AC FLEXIBLE CURRENT SENSOR series can measure commercial power lines up to 6000 A, including solar power conditioner output. Even thick cables can be wired easily among crowded wiring or in narrow locations.

External Power Supply Not Needed for Sensor Connections

Power can be supplied to the current sensor from the main unit, so there is no need to provide a separate external power supply for the current sensor. Connected sensors are recognized automatically, for reliable and quick measurements.

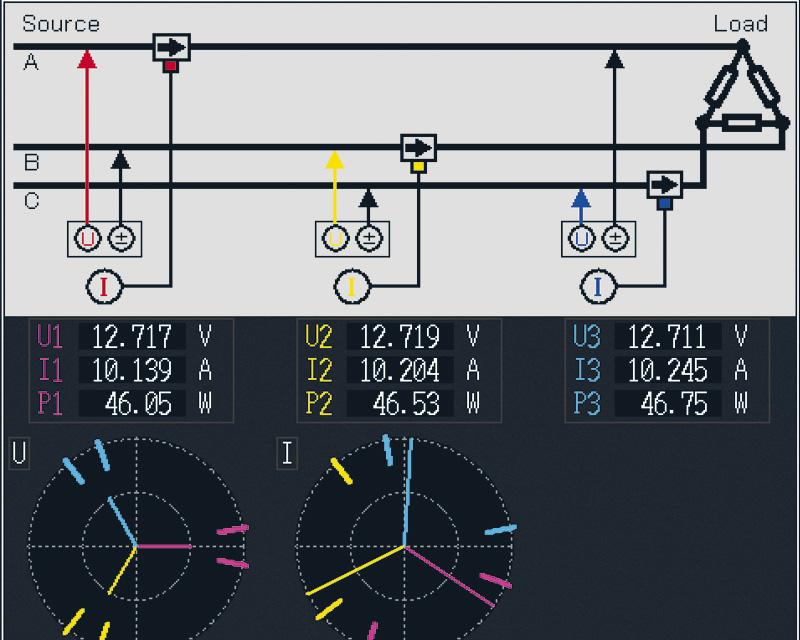

Wiring Displays and Quick Setup Lets You Begin Measuring Immediately

Perform wiring while checking wiring diagrams and vectors on the screen. Optimum settings are performed automatically simply by selecting a connection and using the quick setup function.

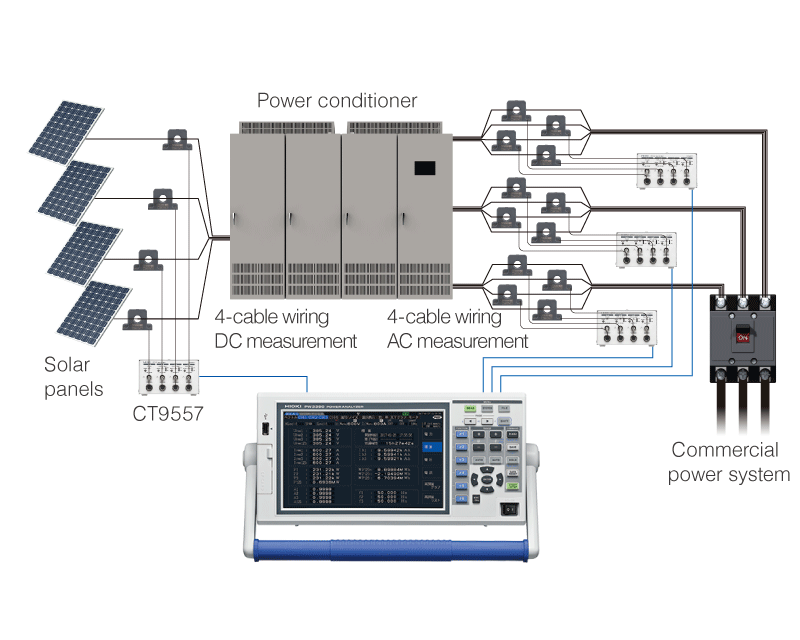

New Method for Measuring Large Current over Multi-Cable Wiring

Highly accurate measurement of current in multi-cable wiring with large currents has been difficult-until now. The CT9557 adds the output waveforms from the high accuracy sensors connected to each branch line of the multi-cable wiring, for the highly accurate measurement of large currents.

Extensive Interface for Linking with External Devices

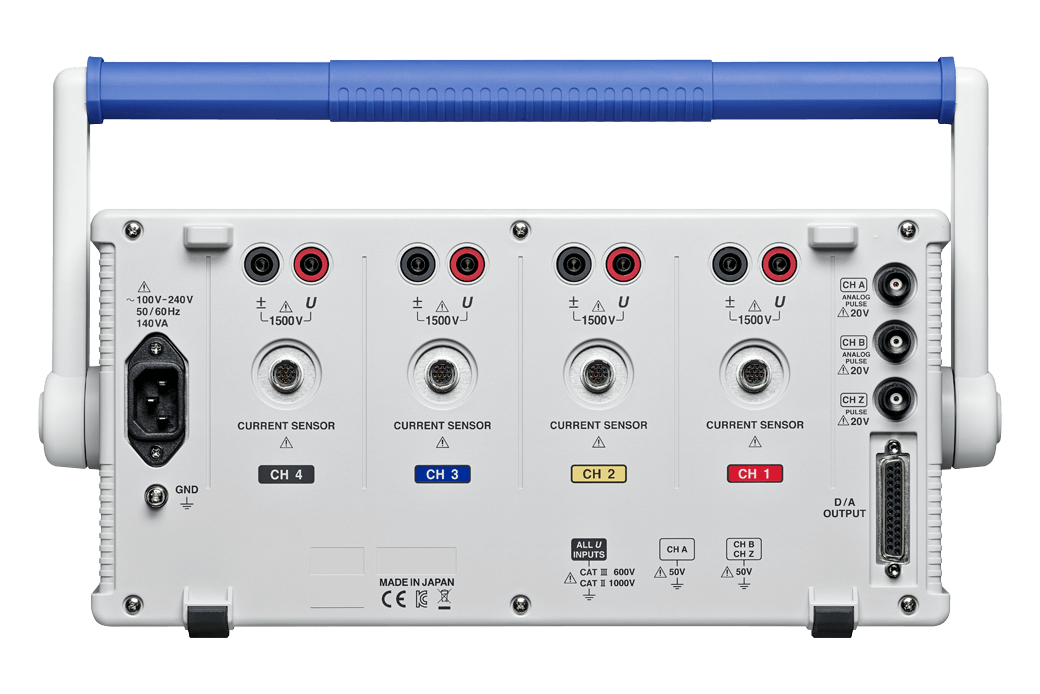

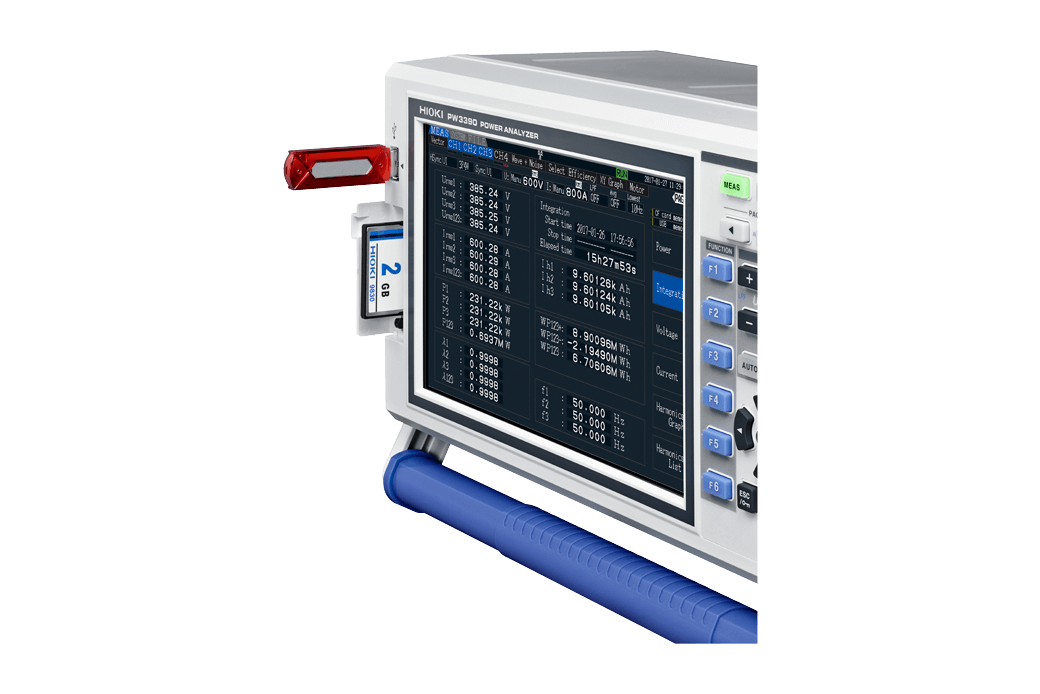

Wide variety of built-in interfaces, including LAN, USB (communication, memory), CF cards, RS-232C, synchronization control, and external control.

D/A output* delivers analog output at 50 ms for up to 16 parameters. The voltage and current waveform for each channel can also be output.

* Built-in for PW3390-02 and PW3390-03

Switch Screens with a Single Touch, Accessing a Variety of Power Analysis Methods

The power analysis engine allows the simultaneous, parallel calculation of all parameters. Access a variety of analysis methods simply by pressing the page keys to switch screens.

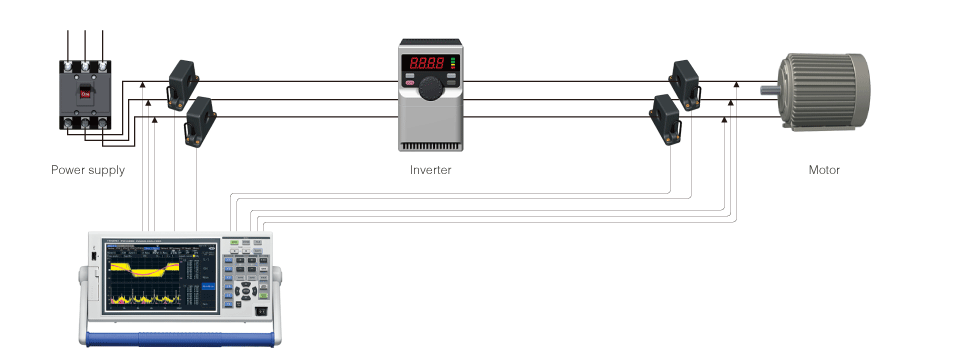

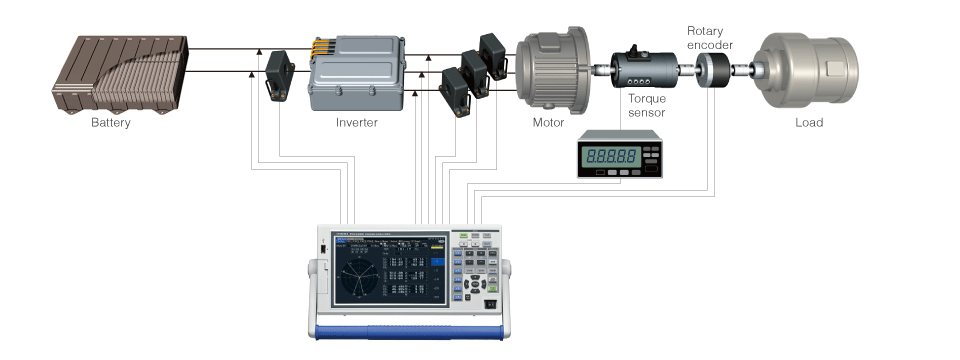

Measure the Power Conversion Efficiency of Inverters

Highly Accurate and Fast 50 ms Calculation of Power in Transient State

Measure power transient states, including motor operations such as starting and accelerating, at 50ms refresh rates. Automatically measure and keep up with power with fluctuating frequencies, from a minimum of 0.5Hz.

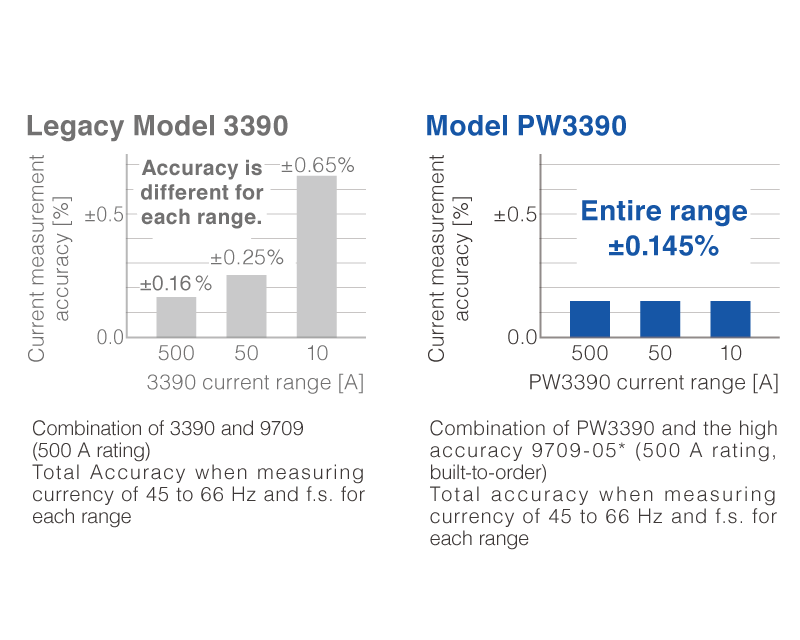

Combined Accuracy of Current Sensors Applicable throughout Entire Range

Combined accuracy throughout the entire range is provided through the use of a built-to-order high accuracy pass-through type current sensor. Obtain highly accurate measurements regardless of range, from large to minute currents, even for loads that fluctuate greatly.

* High-accuracy specifications are not defined for the built-to-order high accuracy current sensor when used alone.

Measure High-Frequency Noise in Inverters

Power supply problems caused by high switching inverter frequencies are unrelated to the fundamental frequency, making it difficult to conduct proper harmonic analysis. The noise analysis function performs a frequency analysis of noise components up to 100 kHz, and displays the frequency, and voltage and current levels for the top 10 points. This is effective for measuring high-frequency noise in inverters.

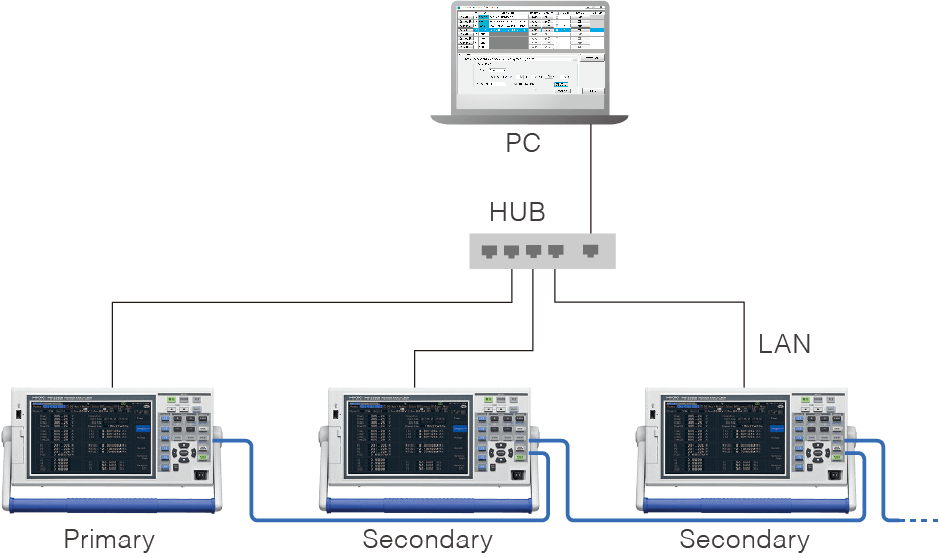

Acquire Data from up to 8 Synchronized Units (32 Channels)

When you connect CONNECTION CABLE 9683 to multiple PW3390 units, the control signals and internal clocks synchronize. From the primary unit, you can control the measurement timing on the PW3390 units that are set as secondaries. With interval measurement, you can save synchronized measurement data to a CF card or a PC to achieve simultaneous measurements across a larger number of systems.

Analyze and Measure EV/HEV Inverter Motors

Electric Angle Measurement of Motors (PW3390-03 only)

The PW3390-03 features a built-in electric angle measurement function required for vector control via dq coordinate systems in high-efficiency synchronized motors. Make real-time measurements of phase angles for voltage and current fundamental wave components based on encoder pulses. Further, zero-adjustment of the phase angle when induced voltage occurs allows electric angle measurement based on the inductive voltage phase. Electric angle can also be used as an Ld and Lq calculation parameter for synchronized motors.

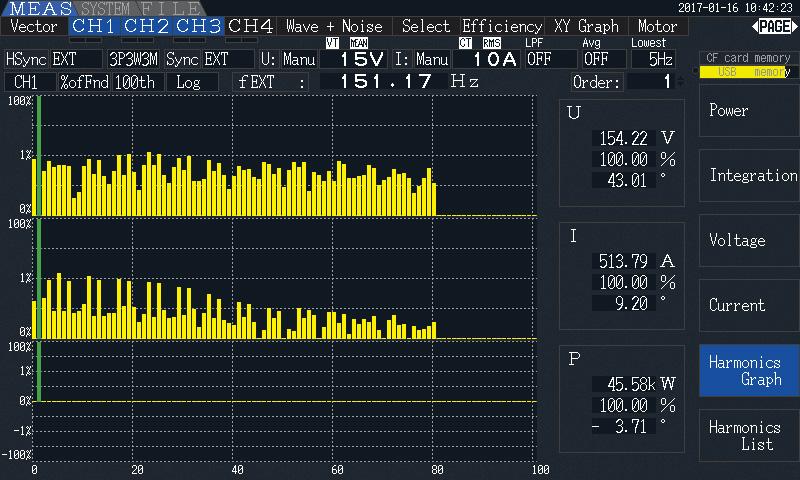

Measure Harmonics with Consideration for PWM Waveform Characteristics

The zero-crossing filter automatically matches the input frequency in the range of 0.5 Hz to 5 kHz to reliably detect the fundamental frequency. Further, harmonic analysis that is based on the fundamental frequency automatically prevents aliasing error using a digital AAF, which allows both precision and measurement reproducibility at a high level.

Transfer to Data Logger via Bluetooth® wireless technology

Connect the PW3390 and a data logger (with support of LR8410 Link) via Bluetooth® wireless technology to wirelessly transmit 8 parameters of measurement values from the PW3390 to the data logger. In addition to the voltage, temperature, humidity, and other parameters measured by the multichannel data logger, you can also integrate the measurement values of the PW3390 and observe and record them in real time.

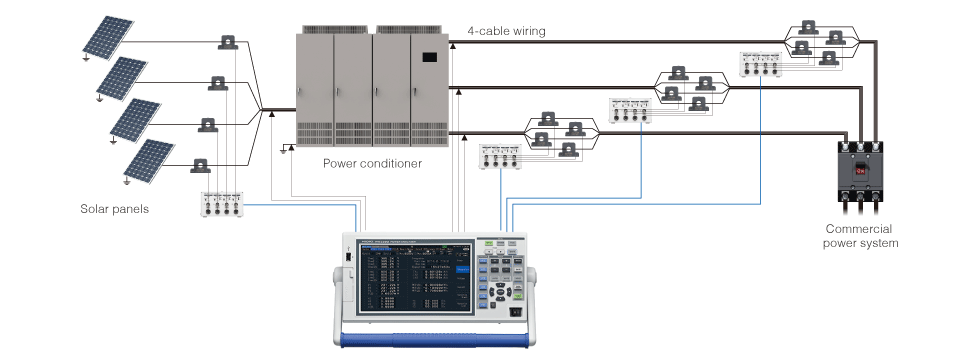

Measure the Efficiency of PV Power Conditioners (PCS)

HIOKI's Current Measurement Solutions for Large Currents of 1000 A or More

Introducing a lineup of sensors taking measurements up to 6000 A for 50 Hz/60 Hz, and up to 2000 A for direct current. The CT9557 SENSOR UNIT lets you add the output waveforms from multiple high accuracy sensors. Use multi-cable wiring lines to take highly accurate measurements of up to 4000 A.

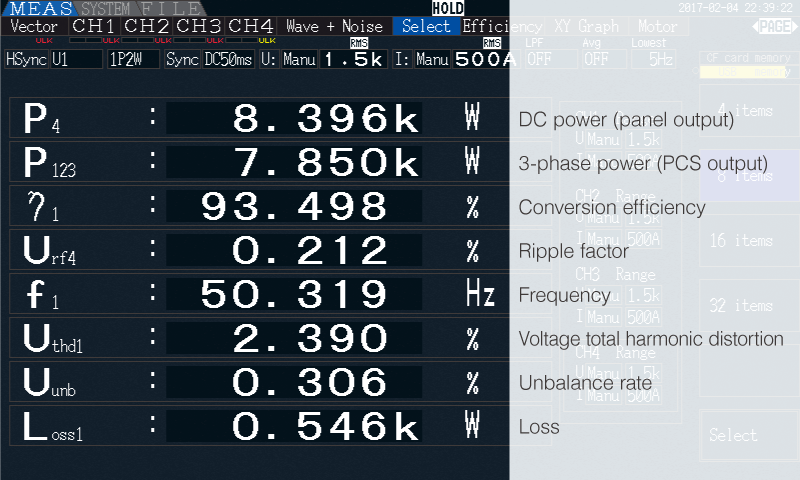

Support for PCS Parameters

Simultaneously display the parameters required for PCS, such as efficiency, loss, DC ripple factor, and 3-phase unbalance rate. Easily check the required measured items for improved test efficiency. By matching the measurement synchronization source for both input and output, you can perform DC power measurements that are synchronized with the output AC as well as stable efficiency measurements.

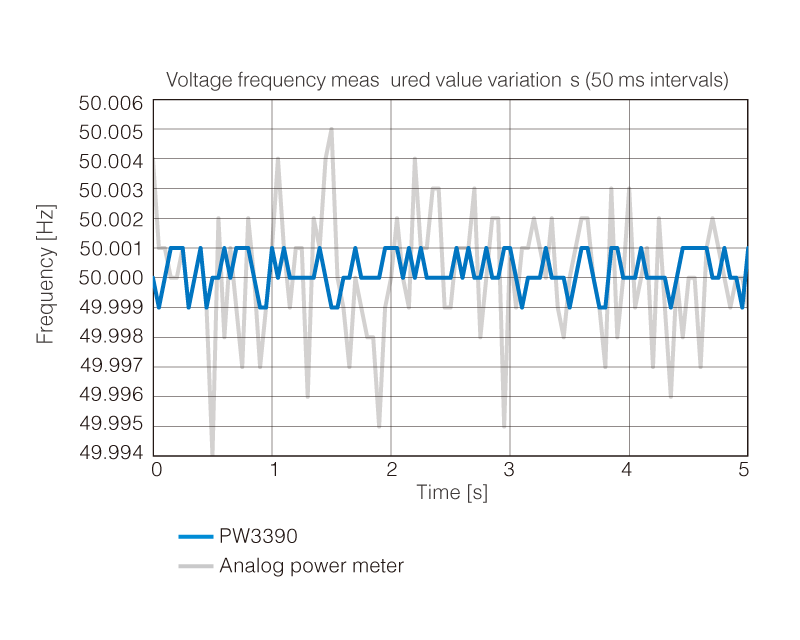

±0.01 Hz Basic Accuracy for Voltage Frequency Measurements

Perform the frequency measurements that are required for various PCS tests with industry-leading accuracy and stability. Take highly accurate frequency measurements on up to 4 channels simultaneously, while also measuring other parameters at the same time.

Software

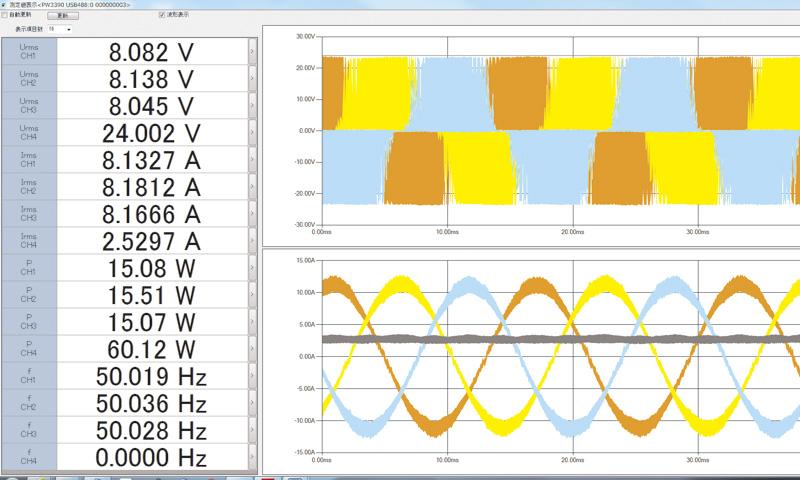

PW Communicator PC Communication Software

PW Communicator is an application program for communicating between a PW3390 series power analyzer and a PC. It includes many useful functions, such as configuring PW3390 settings, monitoring measurement values, saving CSV data, and calculating efficiency.

-Numerical value monitoring

Display the PW3390's measurement values on the PC screen. You can freely select up to 32 values, such as voltage, current, power, and harmonics.

-Waveform monitoring

Monitor the measured voltage, current, and waveforms on the PC screen.

-Meter setting

Change the settings of the connected PW3390 from the PC screen.

-Measure with multiple units

In addition to the PW3390, it is also possible to perform batch control of up to 8 devices from the HIOKI PW6001 Power Analyzer and the PW3335, PW3336, and PW3337 Power Meter series. You can also simultaneously record measured data to the PC, and perform efficiency calculations for measuring instruments.

-Record in CSV format

Record measured data to a CSV file at regular time intervals. The minimum recording interval is 50 ms.

Rackmount

Rackmount fittings

For EIA or JIS. Please contact your authorized Hioki distributor or reseller for more information.

Basic specifications

| Measurement line type | Single-phase 2-wire, single-phase 3-wire, three-phase 3-wire, three-phase 4-wire, Voltage 4 channels, Current 4 channels, Isolated between each channel | |||||

|---|---|---|---|---|---|---|

| Measurement items | Frequency, RMS voltage, voltage mean value rectification RMS equivalent, voltage AC component, voltage simple average, voltage fundamental wave component, voltage waveform peak +, voltage waveform peak -, voltage total harmonic distortion, voltage ripple factor, voltage unbalance factor, RMS current, current mean value rectification RMS equivalent, current AC component, current simple average, current fundamental wave component, current waveform peak +, current waveform peak -, current total harmonic distortion, current ripple factor, current unbalance factor, active power, apparent power, reactive power, power factor, voltage phase angle current phase angle, power phase angle, positive-direction current magnitude, negative-direction current magnitude, sum of positive- and negative-direction current magnitude, positive-direction power magnitude, negative-direction power magnitude, sum of positive- and negative-direction power magnitude, efficiency, loss Current integration, active power integration |

|||||

| PW3390-03 only: Torque, Rotation, Frequency, Slip, or Motor power | ||||||

| Harmonic measurement | Input: 4 ch, Synchronization frequency range: 0.5 Hz to 5 kHz, Number of harmonic orders: Max. 100th order |

|||||

| Noise measurement | Number of channels: 1 ch (select one channel from CH1 to CH4), Maximum analysis frequency: 200 k/ 50 k/ 20 k/ 10 k/ 5 k/ 2 kHz |

|||||

| Motor Analysis (PW3390-03 only) |

Input: 3 ch (CH A, CH B, CH Z), Measurement parameters: Voltage, torque, rotation rate, frequency, slip, and motor power | |||||

| Measurement range | Voltage range: 15 to 1500 V, 7 ranges Current range: 0.1 A to 20 kA (depends on current sensor) |

|||||

| Effective measuring power range | 0.0150 W to 39.600 MW (determined automatically by the combination of voltage range, current range, and measurement line) | |||||

| Basic accuracy (45 to 66 Hz) |

Voltage: ±0.04 % rdg. ±0.05 % f.s. Current: ±0.04 % rdg. ±0.05 % f.s. Active power: ±0.04 % rdg. ±0.05 % f.s. |

|||||

| Synchronization frequency range |

0.5 Hz to 5 kHz | |||||

| Frequency band | DC, 0.5 Hz to 200 kHz | |||||

| Data update rate | 50 ms (For harmonic/frequency measurement, depends on the synchronization frequency when less than 45 Hz) | |||||

| Display refresh rate | 200 ms (Independent of internal data update rate; waveform and FFT depend on the screen) | |||||

| Auto-Save Functions | Each value is stored to CF card during every measurement interval (not available for USB storage), OFF, 50 msec to 500 msec, 1 sec to 30 sec, 1 minute to 60 minutes, 15 settings | |||||

| External interfaces | LAN, USB (for communication/ memory), RS-232C (for communication/LR8410 link), CF card, Synchronization control, External Control | |||||

| Logger connectivity |

Sends measured values wirelessly to logger by using a BluetoothⓇ wireless technology serial conversion adapter. (Supported devices: Hioki LR8410 Link-compatible loggers) | |||||

| Power supply | 100 to 240 V AC, 50/60 Hz, 140 VA max. | |||||

| Dimensions and mass | 340 mm (13.39 in)W × 170 mm (6.69 in)H × 156 mm (6.14 in)D, 4.6 kg (162.3 oz) | |||||

| Included accessories | Instruction Manual ×1, Power cord ×1, Measurement Guide ×1, USB cable ×1, Input cord label ×2, D-sub connector × 1 (PW3390-02, PW3390-03) | |||||

Direct Current Input (1)

* To connect to the HIOKI ME15W (12 pin) terminal

Up to 200 A (High precision) (9)

To connect to the Hioki ME15W (12 pin) terminal

Up to 500 A (High precision) (5)

To connect to the Hioki ME15W (12 pin) terminal

Up to 2000 A (High precision) (4)

To connect to the Hioki ME15W (12 pin) terminal

Up to 8000 A (High precision) (2)

Aggregate and measure large currents in multi-cable circuits

Use multiple AC/DC Current Sensor CT6877A units with the Sensor Unit CT9557 to measure currents of up to 8000 A in multi-cable circuits. Requires 1 connection cable to connect the PW6001/PW3390 to the CT9557.

ME15W (12 pin) terminal to ME15W (12 pin) terminal, 1 m (3.28 ft) length (for connecting CT9557 total output to PW6001 or PW3390 only)

PL23 (10 pin) - ME15W (12 pin) conversion (1)

When using a PL23 terminal sensor without “-05” in the model number, Conversion Cable CT9900 must be used to connect to ME15W terminal.

When using the CT6865 and CT6846 (without “-05”), connection via the CT9900 and manual settings are required on the main device.

Convert PL23 (10-pin) terminal to ME15W (12-pin) terminal

Current Input 2000A AC/DC (3)

The CT9920 is necessary for connecting the current sensor with Hioki PL14 to the PW3390

Required to connect the PW3390 or other instrument’s ME15W terminal to a current sensor with a PL14 output connector.

Current Input 6000A (2)

The CT9920 is necessary for connecting the current sensor with Hioki PL14 to the PW3390

Required to connect the PW3390 or other instrument’s ME15W terminal to a current sensor with a PL14 output connector.

Voltage Input (11)

Red/ Yellow/ Blue/ Gray each 1, Black 4, 3m (9.84ft) length, Alligator clip ×8

Banana branch-banana, Red: 1, 0.5 m (1.64 ft) length, for branching from the L9438s or L1000s, CAT IV 600 V, CAT III 1000 V

Banana branch-banana, Black: 1, 0.5 m (1.64 ft) length, for branching from the L9438s or L1000s, CAT IV 600 V, CAT III 1000 V

1.6 m

3.0 m

Expands the length of L4930/4940, 1.5 m (4.92 ft) length

Attaches to the tip of the banana plug cable, Red/Black: 1 each, 185 mm (7.28 in.) length, CAT II 1000 V

1000 V specifications, Black/ Red, 3 m (9.84 ft) length, Alligator clip ×2

When three-phase 3-wire connection, the voltage cord to be connected can be reduced from 6 to 3

When three-phase 4-wire connection, the voltage cord to be connected can be reduced from 6 to 4

Connection Options (7)

L9217: for motor analysis input

Cord has insulated BNC connectors at both ends, 1.6 m (5.25 ft) length

Cord has insulated BNC connectors at both ends, 3.0 m (9.84 ft) length

Cord has insulated BNC connectors at both ends, 10 m (32.81 ft) length

9 pin - 9 pin, cross, 1.8 m (5.91 ft) length

Straight Ethernet cable, supplied with straight-to-cross conversion adapter, 5 m (16.4 ft.)

For synchronization, cable length 1.5 m (4.92 ft)

Receiving side BNC (female), output banana (male) *Not compatible with older generation Memory Hicorders with banana input terminals

Storage media (3)

PC Card Precaution

Use only PC Cards sold by Hioki. Compatibility and performance are not guaranteed for PC cards made by other manufacturers. You may be unable to read from or save data to such cards.

Carrying case (1)

Hard trunk type

PC peripherals (1)

Other options (0)

Please contact your authorized Hioki distributor or reseller for more information.

• D/A output cable D-sub 25-pin - BNC (male)

• Rackmount fittings (For EIA or JIS)

• PW9100 5A-rated model

• 9709-05 high-accuracy model

• CT6862-05 high-accuracy model

• CT6863-05 high-accuracy model

• 2000A AC/DC high accuracy sensor, pass-through type

- ISO 21782: EV Propulsion Component Test Specifications and Measuring Instruments

- Comprehensive Evaluation of Inverter Motors

- Synchronized Input and Output Measurement of Three-Phase Inverters

- Evaluate the Efficiency of a DC-DC Converter with the PW3390 Power Analyzer

- On-site power efficiency measurement of an EV fast charger