Production

Manufacturing that meets customer expectations

Hioki’s manufacturing philosophy

Commitment to refining our manufacturing capabilities

Individual employees and teams involved with manufacturing at Hioki strive continuously to upgrade their knowledge, experience, skills, and technical capabilities so that we can build even better products and create new value for customers. We’re committed to continuing to refine our overall manufacturing capabilities by increasing collaboration among teams and other organizational units while sharing the joy and value system that characterize manufacturing processes.

Commitment to creating added value

More than simply creating products, our approach to manufacturing focuses on increasing the overall added value inherent in the manufacturing process, including with regard to creativity, services and solutions, and environmental considerations. We’re proud to supply high-quality products and unparalleled services to customers worldwide.

Increasing customer value

Production system

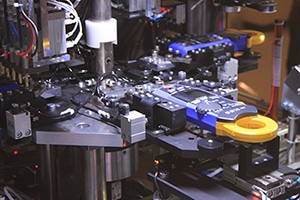

We use an efficient small-lot, multi-model, variable-volume production system with the flexibility to accommodate fluctuations in demand so that we can deliver high-quality products to customers in a timely manner. More than just the sum of its parts, this system is augmented by a personal commitment on the part of each and every Hioki manufacturing employee to serve customers by taking responsibility for, and pride in, quality. This commitment ensures that the products we manufacture meet customers’ expectations.

Delivering peace of mind to customers

After-sales service

We provide precise, reliable repair and calibration service and propose new solutions through sincere, timely service with the goal of delivering peace of mind and value to customers. In this way, we can address the issues and concerns of customers in a variety of regions and operating environments so that they can use Hioki products over the long term.

Pursuing productivity and precision

Manufacturing capabilities

In order to ensure that we can produce the high-quality products our customers demand in the most economic manner possible and supply them in a stable manner, we strive to standardize production processes and manufacturing technologies through efficient, environmentally friendly manufacturing. Due to their nature, electrical measuring instruments are called upon to provide high quality and reliability. We strive to ensure high quality and precision while eliminating variability in our manufacturing operations, including by pursuing automation in a way that creates harmony between human workers and machines.

Creating new customer value

Collaborative development of new products (concurrent engineering)

In order to create new value that can contribute to customers and society, manufacturing personnel participate in the new-product development process from the earliest stages. Collaborative development allows us to make use of relevant data early on in the design of upcoming products, including repair information from after-sales service and “raw” information from manufacturing operations about topics such as productivity issues affecting manufacturing processes.

!["Manufacturing that meets customer expectations" Our approach to manufacturing rests on four pillars that allow us to create value for customers. [Creating customer value] ← Production system / After-sales service / Manufacturing capabilities / Collaborative development of new products "Hioki’s manufacturing philosophy"](/themes/hioki/images/innovation/production-img-01.jpg)