R&D

Creating Innovative Technologies

Research and Development Structures

Hioki’s R&D departments create new products by balancing development of basic technologies needed for future products with design and development of the products demanded by the market today. We have a history of developing proprietary technologies and supplying revolutionary products that address customers’ challenges based on them, including the world’s first technology for no-metal-contact voltage measurement, high-precision current sensing technology, high-frequency measurement technology and laser measurement technology, and micron-level probing technology.

To ensure our ability to appropriately forecast future market trends and plan the necessary technologies and products in response, all engineers emphasize communication with customers and work to create products from customers’ perspective, not only for measurement functionality, but also for safety and overall design.

Our research facility, the Hioki Innovation Center, which was completed in 2015, provides the state-of-the-art experimental research equipment needed for research and development.

Design Policy:“COGNITIVE”

Developing closer relationships with customers, prioritizing richness in terms of sensibility and time in design, and increasing product value: That’s our “COGNITIVE” approach. Hioki takes the sense of excitement that customers feel when they interact with its products into consideration during the design process. Our goal is to create value for customers (by resolving customers’ issues) through product design.

Intellectual Property (IP) Strategy

From a Strategic Trinity to a Patent Landscape

Hioki’s intellectual property (IP) strategy is closed linked to its business and development strategies, with which it comprises a strategic trinity. We are also working to establish a patent landscape(*1) in an effort to advance associated initiatives and more closely integrate IP into our business and development strategies.

- *1:As defined by the Japan Patent Office (JPO), the process of [1] carrying out an analysis that incorporates IP information into management and business conditions and [2] sharing the results (including an overview of the status quo, future prospects, etc.) with managers and others with operational responsibilities (i.e., using the analysis results as an opportunity to dialog) when planning management or business strategy.

Strategic Trinity

Since product features vary by category, we create patent portfolios(*2) to suite each segment and review Hioki’s IP strategy in a timely manner through linkages with our business and development strategies.

- *2:This portfolio encompasses patent maps for Hioki and its markets along with other information such as research into other companies’ patents and analytical results in line with various objectives.

Each component of the strategic trinity is implemented independently, with development strategy informed by discussions of inventions during component technology reviews in the of product planning process and business strategy centered on patent reviews that are embedded in the concurrent engineering process.

![[Strategic trinity] Business strategy, IP strategy, Development strategy](/themes/hioki/images/innovation/rd-img-02.png)

Patent Landscape

Although Japan played a leading role in numerous industries in the past as a result of its state-of-the-art technologies, power relationships have undergone a significant transformation. Hioki too has made major changes in the direction of its intellectual property strategy: whereas the emphasis previously was on strengthening our base in Japan, today we're focused on acquiring rights in major markets overseas while strategically releasing certain domestic rights in Japan.

Intellectual property rights are an important type of intangible property that has a direct impact on the strengthening of pricing power. In a process that integrates closely with management strategy, Hioki is strengthening its management of risks associated with infringement of third-party rights and third-party infringement of its rights under the assumption that applicable rights will be exercised, based on an analysis of intellectual property trends that’s informed by various countries’ laws and regulations.

In addition, we actively communicate information to foster an IP-informed mindset on the part of employees, for example by publishing progress towards achieving IP-related KPIs on an internal dashboard.

Patents, Designs, and Trademarks

Intellectual Property Applications

Hioki offer invention bonuses an incentive to foster engineers’ drive to invent new technologies, and we provide support for patent applications over the long term.

We strive to effectively use and protect the intellectual property rights we acquire as important company assets that help improve brand value.

Patent Ownership

By working with customers to solve their problems, Hioki's strengthening the competitiveness of measurement solutions based on core technologies through "defensive" patents, and we’re expanding our business domain so that we can embrace new challenges with "offensive" patents.

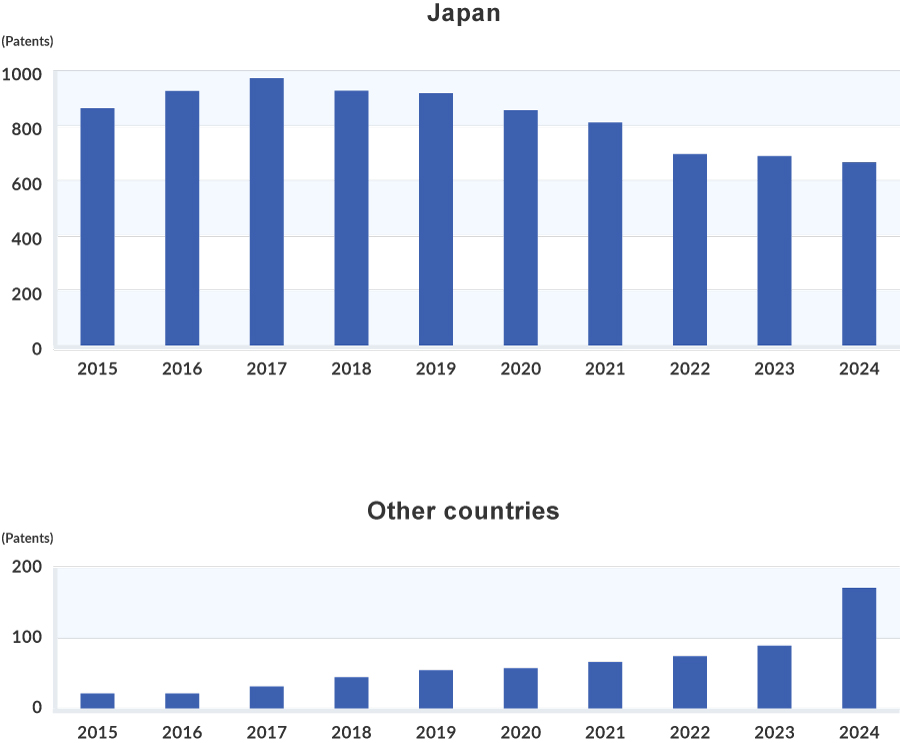

We own some 1000 domestic patents covering measurement technologies, which have developed alongside Japan's advanced technologies over many years. Recognizing the need to allocate management resources to the acquisition of patent rights overseas as global markets grow, we're strengthening our overseas patent applications while carefully examining the effectiveness of domestic patents and releasing certain rights.

For overseas patents, we decide where to file applications based on a consideration of the characteristics of industries and patent programs in individual countries.

Number of Patents held

Number of Patents held

Penetration of Hioki's Corporate Brand

"Hioki", our corporate brand, is a registered trademark in 107(*3) countries and regions worldwide, demonstrating how our measuring instruments business has grown to encompass a variety of countries and markets. We work to manage the Hioki brand and to help it penetrate various countries worldwide so that we can provide high-quality products and unparalleled service.

- *3:As of 2020.

Risk Management

Intellectual property comprises an important type of asset for all businesses, and associated rights should be respected. Hioki's Employee Code of Conduct includes a commitment to not infringing on other companies' intellectual property rights. We're working to strengthen our governance structures for intellectual property by putting in place rules, enhancing intellectual search support tools, and offering compliance training on an ongoing basis.