How to Measure Current

Why is it necessary to measure current? Reasons, methods, and precautions

Overview

You can’t see electricity flow with your own eyes. Consequently, specially designed measuring instruments are necessary in order to measure properties such as current. But why is it necessary to measure current in the first place? And how is that accomplished?

This page offers a detailed explanation of reasons for measuring current and methods for using associated instruments.

Necessity of measuring current

Electronic devices are extremely delicate and precise. Consequently, many devices need to be inspected regularly, and maintenance is key. If there were no measuring instruments, it would be difficult to pinpoint problems during maintenance and when equipment breaks down. For this reason, measuring current is an important part of maintaining electronic devices and pinpointing the causes of malfunctions and failures.

There are a number of measuring instruments that can be used to measure current. The following three are the most frequently used:

- Digital multimeters

- Current probes (viewing current probe voltage output with an oscilloscope)

- Clamp meters

Digital multimeters

Digital multimeters Current probes

Current probes Clamp meters

Clamp meters

Each of these instruments can be used to measure current. It’s important to choose the best instrument for your application.

This page explains how to measure current using each type of instrument.

How to measure current with a digital multimeter

A digital multimeter is an instrument that provides functionality for making basic measurements of electric circuits, from current to voltage and resistance. Various types are available, ranging from large models to card-style devices, and they're used in a variety of electricity measurement scenarios.

Most digital multimeters have a rotary switch for changing functions, so the first step is to set the instrument to the current function.

Then, connect the test leads’ black (negative) terminal to “COM” and the red (positive) terminal to “A.” When connecting the test leads to the circuit, connect the black lead to the power supply’s negative side and the red lead to the load side so that the instrument is in series with the circuit.

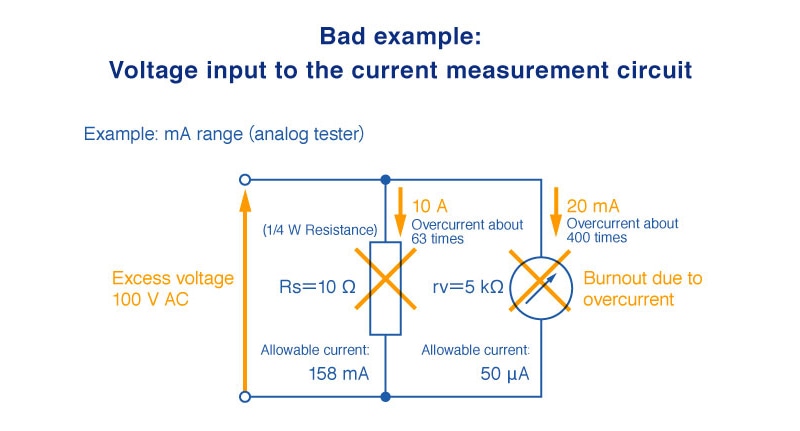

Caution is necessary as inputting a voltage while the test lead is inserted into the “A” terminal could damage the digital multimeter. Consequently, it’s good practice to turn off power to the circuit under measurement so that a voltage is not applied inadvertently. Then connect the current in series with the measurement terminals and turn the power back on.

How to measure current with a current probe

A current probe is a tool that allows an instrument such as an oscilloscope to measure current waveforms by converting current into voltage. They’re useful in a wide range of current measurement scenarios because they allow signal observation from outside insulation (without cutting the cable or other conductor), and because they can accommodate currents of various magnitudes.

The following six types of current probes are available, and should be selected according to the application.

CT type

These current sensors are designed exclusively to measure AC currents. They are comparatively inexpensive and do not require a power supply, although they cannot be used to measure DC currents.

Hall element type

These current sensors can be used to measure both AC and DC currents. They’re inexpensive, but they suffer from disadvantages including comparatively poor precision and drift caused by temperature and time, which makes them poorly suited to applications in which current must be measured over an extended period of time.

Rogowski type

These probes measure current by converting the voltage induced in an air core coil by the AC magnetic field that occurs around the current being measured. They're inexpensive, and they can measure large currents since their lack of a magnetic core eliminates the issue of magnetic saturation. Additionally, they don’t suffer from the disadvantage of magnetic loss. However, they're susceptible to the effects of noise and therefore poorly suited to high-precision measurement. Additionally, they have the disadvantage of not being able to measure DC currents due to the principle of their operation.

AC zero-flux type

These probes improve the characteristics of CT-type probes in the low-frequency band. Thanks to low phase error, they can make measurements across a broad frequency band, making them well suited to power measurement. However, they utilize the CT method and therefore cannot measure DC currents.

AC/DC zero-flux type (Hall element detection type)

These sensors combine the CT method with a Hall element, allowing them to measure both DC and AC current.

AC/DC zero-flux type (fluxgate detection type)

These sensors combine the CT method with a FG (fluxgate) element, allowing them to measure both DC and AC current.

Since the fluxgate exhibits an extremely small offset drift across a broad temperature range thanks to its operating principle, it can achieve exceptionally accurate and stable measurements, making this type of current sensor ideal for pairing with high accuracy power meters for uncompromising precision

How to measure current with a clamp meter

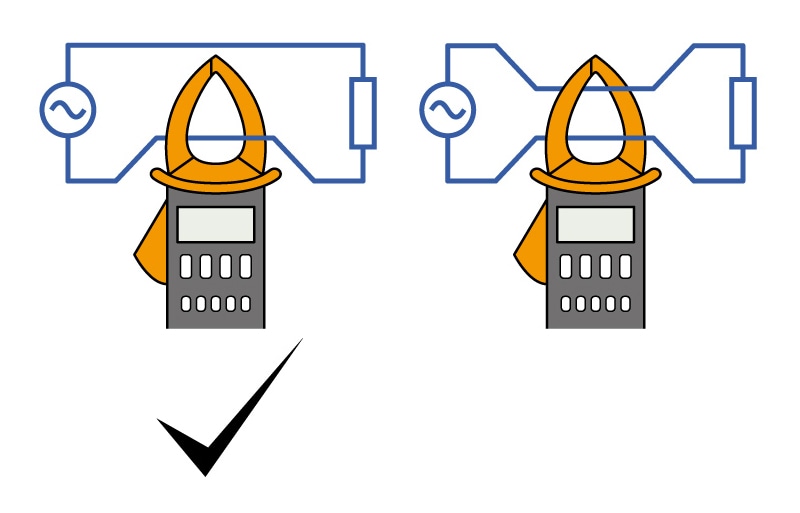

To measure current with a clamp meter, first set the rotary switch to "A". Then execute zero adjustment and clamp the jaws across the cable. Since clamp meters can measure current simply by being clamped around a cable, they can also be used to check current values without cutting circuits. These instruments utilize the fact that the magnetic field that occurs when current flows is proportional to the magnitude of the current; by measuring that field, the current can be measured.

If a clamp meter is clamped around two round-trip wires, the magnetic fields will cancel each other out. It’s necessary to avoid clamping the meter around such pairs of wires, except when measuring leakage current.

Since the magnetic field increases in proportion to the number of coil turns in the same direction around the clamp’s core, precision can be increased by adding turns to the instrument to strengthen the magnetic field.

Choosing the best instrument for your application

Measuring instruments are necessary in order to measure properties such as current in order to maintain and pinpoint malfunctions in precise, delicate electronic instruments. Instruments such as digital multimeters, current probes, and clamp meters are often used to measure current. Why not try using an instrument that suits your requirements and purpose to measure current?

Applications

- DC Large Current and Power Conversion Efficiency Measurement of Plating System Power Supplies

- Measure Energy Savings Using a Small Clamp Logger

- Verify the Energy Savings Created By Photovoltaic (PV) Systems

- Automotive Electrical Equipment and ECU Current Measurement

- Evaluating High-Speed Switching Devices

- TDD Measurement as Specified in the IEEE519 Standard