Verify the Energy Savings Created By Photovoltaic (PV) Systems

How is Energy Savings Measured?

The process of measuring energy savings is known as “Measurement & Verification” or “M&V” whereby measurement technologies are used to reliably identify the actual savings created as a result of energy saving measures. Although energy savings cannot be directly measured because that represents the absence of energy consumption, you can determine the effects of energy saving measures by comparing the energy cost before and after the installation of new equipment such as a solar or photovoltaic (PV) panels.

M&V activities include, among others:

• Installing meters

• Gathering data

• Developing computation methods to analyze data and plotting it against energy rates

• Reporting and quality assurance efforts

Often it is necessary to report to a customer or third party of the effects of the energy saving measures; in any case, it is always wise to verify that any new installed equipment is successful in cutting energy costs.

M&V activities include, among others:

• Installing meters

• Gathering data

• Developing computation methods to analyze data and plotting it against energy rates

• Reporting and quality assurance efforts

Often it is necessary to report to a customer or third party of the effects of the energy saving measures; in any case, it is always wise to verify that any new installed equipment is successful in cutting energy costs.

Measuring and Computing Cost Savings

When verifying the effectiveness of PV equipment in reducing energy costs, the simplest way is to compute savings in monetary units based on the same energy usage before and after the installation. This method is sufficient for a typical household. However, large industrial facilities that invest heavily in energy savings equipment operate on a scale such that close monitoring of power consumption and energy conversion can lead to huge savings. In addition, some power utilities provide incentive programs to buy back any excess energy a PV system generates. This further increases the savings, but complicates the computations even more.

What Type of Power Meter Should be Used to Measure Energy Savings?

M&V processes should be as accurate as required, but the costs should be small relative to the actual costs savings of the project. It is not practical to spend a tremendous amount of time and money on data analysis and computations only to find that those expenses were larger than the actual savings. To that end, a power meter that can provide the following functions can make the M&V process more expedient and efficient:

2. Measure and present equipment output in terms of voltage and frequency changes

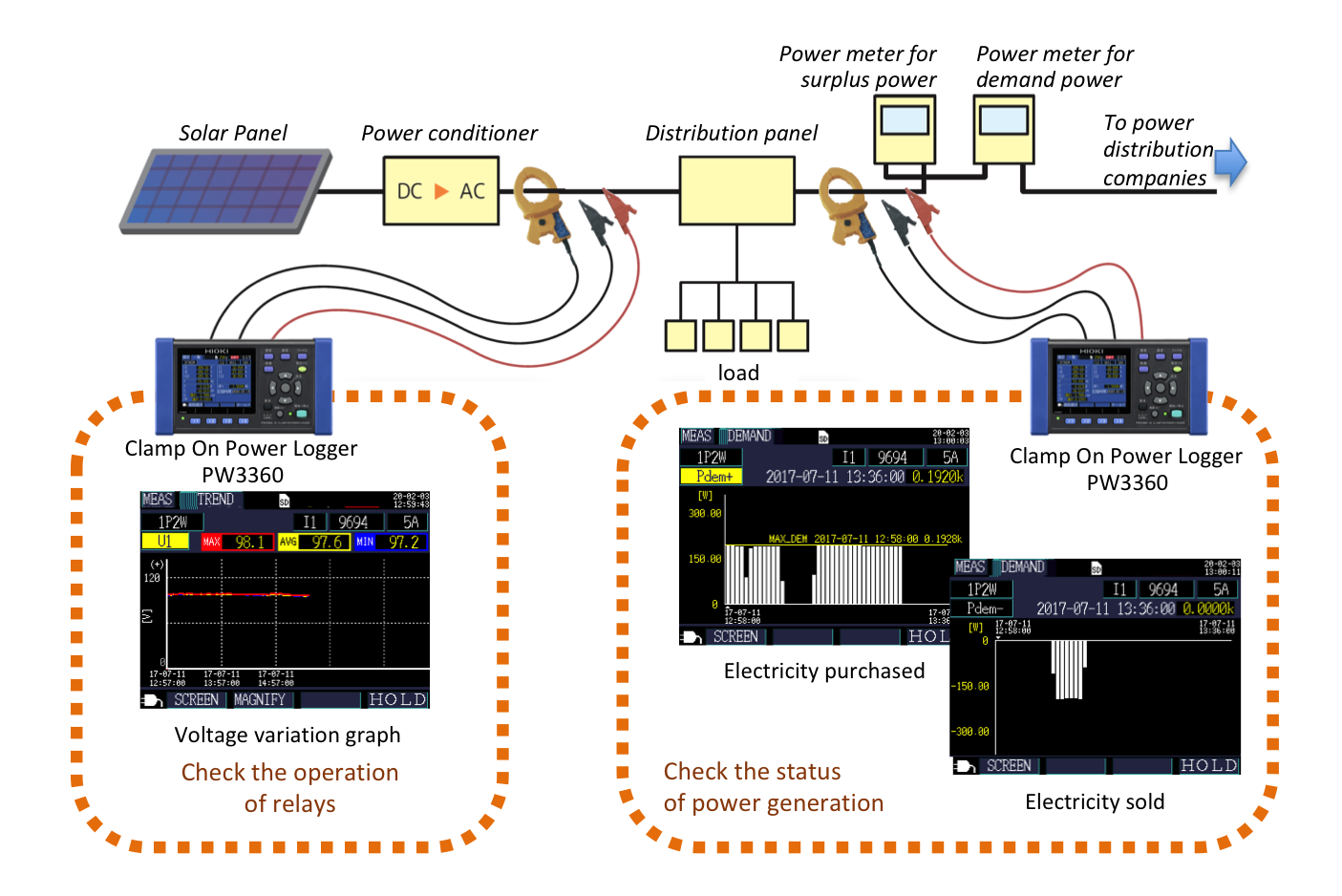

3. Measure the amount of electricity purchased from and sold to the utility company

A Solution in the HIOKI PW3360 Clamp On Power Logger

The PW3360 Clamp On Power Logger is a compact, 3-phase 4-wire energy logger utilizing clamp sensor input to accurately and safely measure power on single-phase to three-phase lines. The illustration shows how 2 power loggers can provide the information necessary to aid in the M&V process:

2. Compute electricity charges by specifying the unit cost (per kWh) so that the PW3360 can multiply the electricity charge unit cost by the active energy (power consumption) WP+ value.

3. Measure the output of the system’s power conditioner to display voltage and frequency changes in order to verify correct operation of relays.

4. Use the demand and energy fluctuation graphs to verify operation of the PV system in real time and make equipment adjustments where necessary to continuously optimize the system.

Advanced Energy Analysis

For more advanced surveys of power quality, we recommend the HIOKI PQ3198 or the PQ3100.