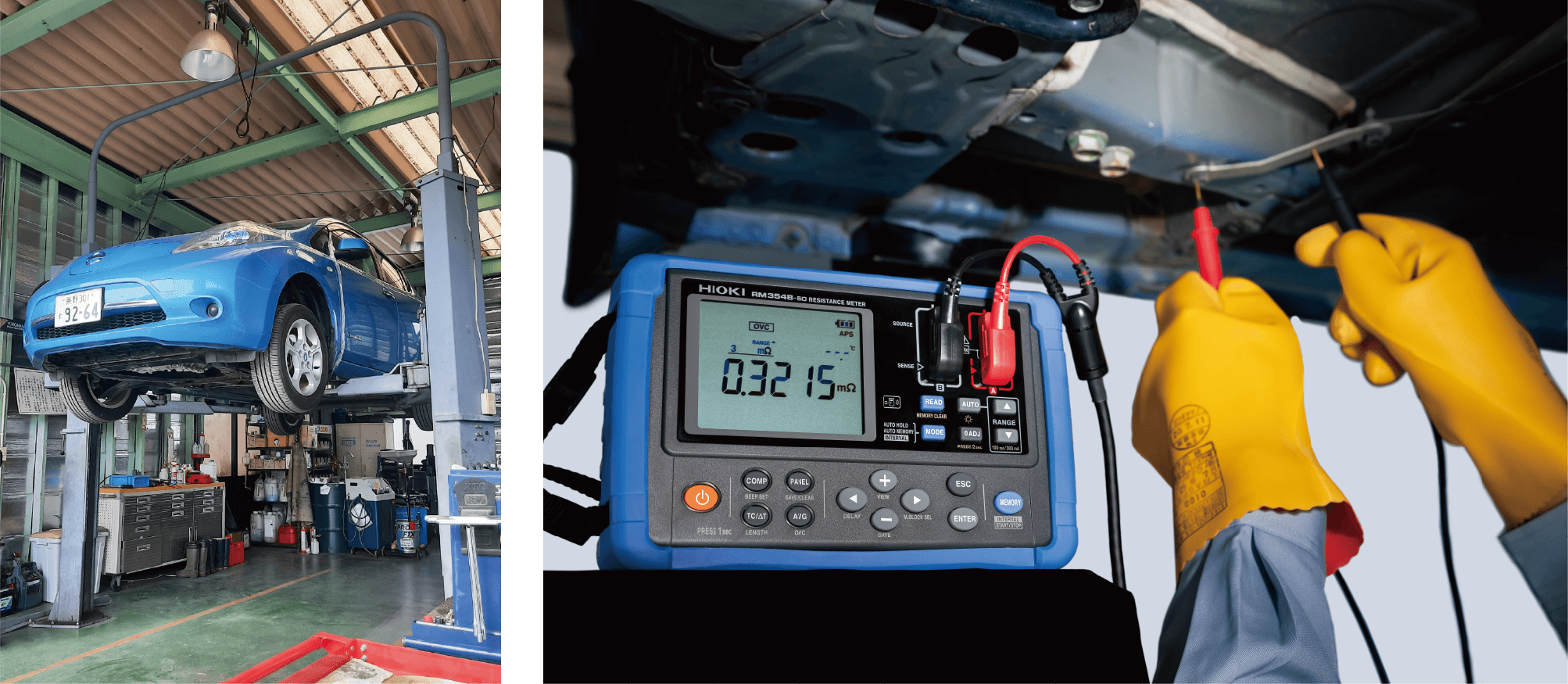

Equipotential Bonding Test of Electric Vehicles (EV)

Regular service and maintenance are required for a safe operation of the battery-powered electric vehicle (BEV). When maintaining or inspecting a BEV, a technician conducts not just mechanical tests but also electrical tests. For example, measurements like zero-voltage are conducted to check that the BEV is not powered, or insulation resistance tests are performed to check that there are no insulation defects. Among such electrical tests, is the equipotential bonding test. Equipotential tests are conducted to check that all exposed conductive parts, such as the chassis of the vehicle, are equipotential or at the same voltage. In this article, you will learn about the equipotential bonding test and the equipment required to do this test, an essential part of the repair or inspection of electric vehicles.

Measurement purpose

This test is performed after the installation or replacement of high-voltage (HV) components. In this test, the technician needs to verify that all chassis, shields, and other components are electrically connected without any issues. The resistance of the ground connection at the area where the chassis of the vehicle and the HV components are connected is measured. If the resistance value is high or substantially unstable (high variability), the HV component's connection may have been improperly installed.

Measurement flow

- 1.Be sure to shut down the vehicle's HV system by disconnecting the service plug or switch before carrying out any electrical testing or measurements.

- 2.After performing the zero-voltage measurement and other safety procedures, confirm that the vehicle is completely shut down. Then, you can safely proceed with the equipotential bonding test.

- 3.Before measuring, make sure that the tips of the test leads to be used are clean and not worn. Place the test lead on the object that is known to have a resistance of zero ohms, and verify that the measuring instrument can accurately conduct the measurement. Remove any dirt, etc., as that may affect the measured resistance value.

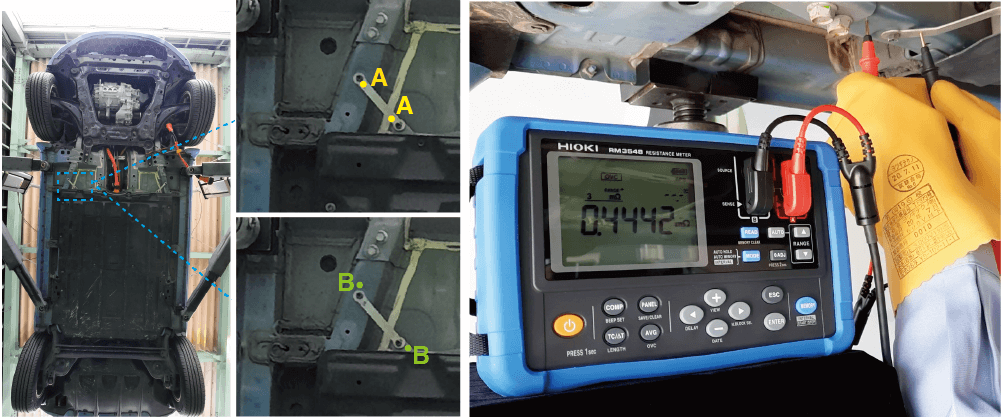

- 4.As shown in Fig. 1, measure the resistance between the bonded parts of the vehicle chassis.

- 5.Table 1 shows an example of a measurement result. Check that the measured value is close to zero ohms and that there is no significant difference in the resistance value depending on the measurement location.

- 6.Record the measurement results if needed.

Caution: The removal of high-voltage components is hazardous work. Ensure that qualified personnel specified by the laws and regulations with professional training perform the work. For details of the equipotential bonding test, please follow the operation manual of each vehicle manufacturer.

Fig. 1: Example of measurement locations

Table 1: Example of measurement results

| Bonding issue | Measured value A | Measured value B |

|---|---|---|

| No | 0.6032 mΩ | 0.7010 mΩ |

| Yes | 0.6035 mΩ | 25.670 mΩ |

Measuring instrument for conducting the equipotential bonding test

The resistance value measured in the equipotential bonding test is as low as 0.1 ohms or less, so a DC miliohm meter that uses a four-terminal measurement method (four-wire Kelvin) is used. Strictly speaking, a digital multimeter is also capable of measuring resistance. However, due to the low measurement current (e.g., 0.2 mA), it is challenging to measure low resistance with high accuracy.

On the other hand, a four-terminal DC miliohm meter uses relatively large currents (e.g., 1 A) when measuring resistance, which allows low resistance to be measured with high accuracy. Furthermore, the ECE-R-100 *1 standard states that the resistance between all exposed conductive parts and the electrical chassis must be less than 0.1 ohm when a minimum of 0.2 amperes of current is flowing, which can be interpreted as the importance of using equipment that uses higher current for resistance measurement.

The 4-terminal DC miliohm meter also provides a high-precision resistance measurement, as the measurement is unaffected by the wiring resistance or contact resistance of the test leads.

- *1:ECE-R-100 is a safety standard for electric powertrains of road vehicles including rechargeable battery systems.

Solutions from Hioki

To perform an equipotential bonding test on an BEV, Hioki recommends the RM3548-50 because of its standard-compliant measurement current, ideal probe options, temperature correction, and wireless data transfer functionality.

1. Standard-compliant measurement current

The RM3548 is a portable 4-terminal DC miliohmmeter. The resistance measurement conducted by this meter with a measurement current ranging from 500 nA to 1 A satisfies the ECE-R-100 measurement current requirement. The meter offers stability and precision in a wide resistance measurement range of 3 milliohms (with 0.1 microohm resolution) to 3 megaohms (with 100 ohm resolution).

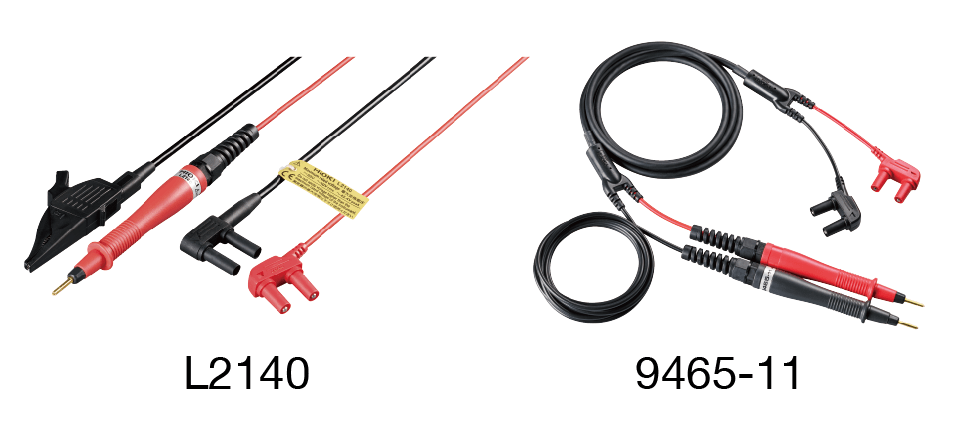

- Note: The pin type lead 9465-11 is sold separately.

2. Probes Designed for EV Maintenance

We recommend two probe options to make your probing tasks more efficient and comfortable:

- L2140: Ideal for testing under the vehicle due to its long cable. The black clip stays fixed while the red probe tests various points.

- 9465-11: Equipped with dual pin probes, perfect for confirming the fastening of nuts and bolts during testing.

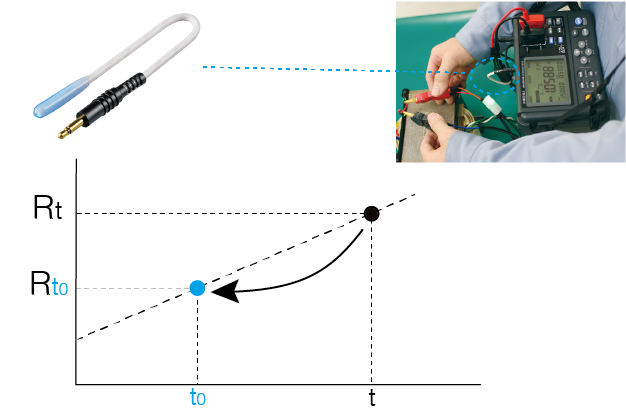

3. Temperature correction

The RM3548 has a temperature correction function. It converts the measured resistance value Rt at the current temperature t to the resistance value Rt0 at the reference temperature t0. This gives you the correct resistance values, even when performing measurements in a variable temperature environment.

4. Easily transfer measurement data to an Excel® file

Excel® Direct Input function allows you to input measurement values directly and automatically into an Excel® file once the instrument's auto-hold function is activated. (Wireless Adapter Z3210 is necessary)

Finally

As the drive for sustainability propels the future of electric vehicle adoption, technicians play a crucial role in performing both electrical tests and mechanical inspections for EV maintenance. Among these tests, the equipotential test assumes a key role in ensuring the safety of the vehicle. The RM3548-50 shines in this aspect, featuring standard-compliant specifications and user-friendly attributes that simplify technician responsibilities. Explore the product page for more information, and contact us if you have any questions about this instrument for guaranteeing the safety of BEVs. At Hioki, we offer solutions that ensure a safe and efficient maintenance of BEVs.