Capture CAN signals over cable insulation

Capture CAN signals over cable insulation

Slashing prep man-hours from 2 days to 10 minutes

Featured customer

Company B is a leading Japanese automaker that’s focusing on expanding markets in developing nations and manufacturing vehicles with high environmental performance. The company is also working to deliver CASE (Connected, Autonomous, Shared & Service, and Electric) capability, a keyword for an era of technological innovation.

Background

Grappling with issues involving the acquisition of signals from CAN wiring, an essential part of vehicle development and evaluation

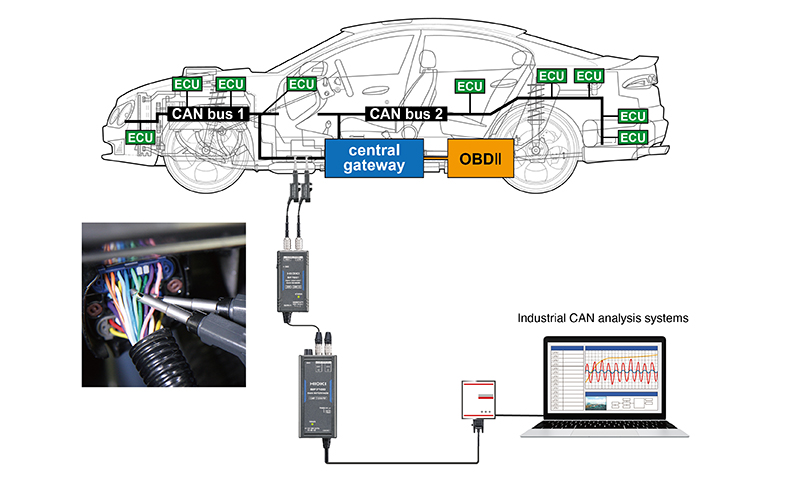

Vehicles designed in recent years incorporate numerous electronic control units (ECUs), which provide electronic control of the engine, motors, brakes, and other components. ECUs interoperate via a vehicle network that allows them to transfer and share data from sensors throughout the vehicle along with control information and other data. Controller Area Network (CAN) is one such network, and it plays a far-reaching role in vehicle control. Company B was using information sent and received via CAN as key indicators in developing and evaluating new vehicle models.

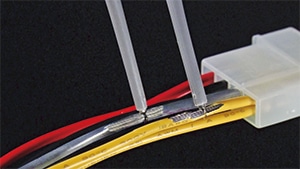

However, acquiring signals from CAN wiring imposed an enormous man-hour penalty. There are two methods for capturing such signals. One involves stripping back CAN wire insulation and placing measurement probes in contact with the metal portion of the wires. Since this approach compromises the insulation that protects the wires, it raises the risk of electrical shorts and loss of airtightness. The other method involves using a sub-harness to branch the CAN wiring. That approach takes an enormous amount of time since sub-harnesses must be fabricated and then installed.

Using a sub-harness

Using a sub-harness Stripping back insulation

Stripping back insulation

Company B, while understanding that acquiring CAN signals was extremely important in vehicle development, was encountering quality- and workload-related difficulties due to the damage, however slight, caused by signal acquisition to cables in completed test vehicles. The company also occasionally acquired CAN signals used in failure diagnostics from maintenance-use OBD-II terminals and utilized them in new-vehicle evaluation.

Key considerations that led the customer to choose Hioki

Impressing the customer with the ability to easily and consistently acquire CAN signals from outside network wiring

Manufacturers are called upon to rigorously evaluate automobiles so that they can ensure the safety of occupants. For this reason, company B was looking for a more reliable method for acquiring CAN signals that would ensure vehicle quality.

Hioki proposed its Non-Contact CAN Sensor SP7000 series as a solution. The product was the first instrument of its type to be able to acquire CAN signals easily and consistently simply by affixing sensors to the insulation on CAN wires. Company B cooperated in demonstration testing of the product by communicating key requirements in actual vehicle evaluation to Hioki, helping make the SP7000 series an even more useful offering.

Non-Contact CAN Sensor SP7000 series

Non-Contact CAN Sensor SP7000 series

One of the product’s key features is its support for CAN FD, the latest version of the network that can transfer even more data at high speeds. Since there is no central gateway that coordinates signals on networks linking ECUs, the product can acquire all CAN signals. And since the product doesn’t trigger ECU malfunctions or errors like security lockouts, which can be caused by changes in electrical characteristics that occur when probes are connected directly to network wiring, it allows smooth analysis, even during test drives. Recognizing the utility of these features, company B chose to purchase the SP7000 series.

Acquire signals without needing to go through a central gateway

Acquire signals without needing to go through a central gateway

Benefits

Dramatically reducing the number of man-hours required in order to acquire CAN signals, from as much as two days to around 10 minutes

Company B purchased the SP7001, which allows it to acquire CAN signals simply by affixing probes to the insulation around network wires. Today, the company is using the product widely in new-vehicle development and evaluation. Previously, it took up to two days to prepare wiring and install sub-harnesses, with an additional month to procure sub-harnesses from an outside vendor if the company had none on hand. Now, preparation takes about 10 minutes, dramatically reducing the number of man-hours spent on development and evaluation.

Additionally, the fact that signal acquisition doesn’t damage vehicle cables means better test vehicle reliability. There’s no need to modify vehicles, and measurements can be made with peace of mind during driving tests on public roads, even while using self-driving systems.

With the number of ECUs in vehicles poised to grow as safety equipment is enhanced and self-driving vehicles gain adoption, company B considers the SP7000 series’ ability to easily acquire signals from even complex CAN buses to be a major strength. Going forward, CAN FD will likely see greater use as a vehicle network on new automobiles. Acquiring signals in a more reliable manner will be key in developing and evaluating vehicles with CAN FD since the standard’s high communications speeds mean more errors. Company B plans to make full use of the SP7000 series in the future so that it can accommodate such developments.