How to Improve Lithium-Ion Battery Performance by Measuring Electrode Sheet Resistance

Understanding the Role of Internal Resistance in Battery Optimization

The Importance of Electrode Resistance in Battery Development

Lithium-ion batteries are powering the next generation of electric vehicles, renewable energy systems, and portable electronics. Yet, persistent challenges—such as low energy capacity, slow charging, and shortened lifespan—can often be traced back to a less visible issue: internal resistance within electrode sheets.

While battery performance is often evaluated at the cell level, key inefficiencies occur at the microstructural level of the electrode. Measuring this resistance—especially across the composite layer and the interface—offers critical insights for improving battery design and manufacturing.

Understanding Resistance in Electrode Sheet Layers

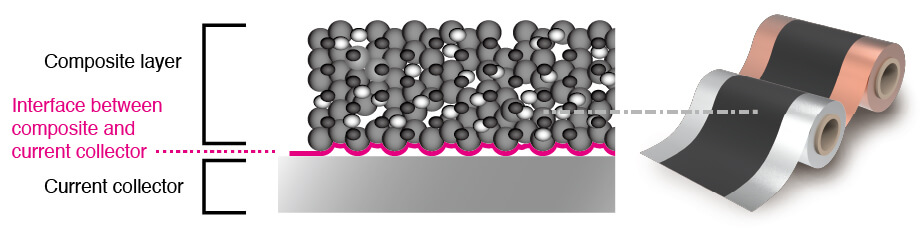

An electrode sheet is made up of three functional layers:

- Composite layer: The active material that stores and releases lithium ions

- Interface layer: The contact surface between the composite and foil

- Metal foil (current collector): The conductive base, usually aluminum or copper

Fig. 1. The 3 functional layers of the electrode sheet from an electrical perspective

Each of these contributes to total resistance. Most conventional measurement tools provide a single, combined resistance value—making it difficult to pinpoint inefficiencies in specific layers.

Hioki’s RM2610 Electrode Resistance Measurement System addresses this limitation by isolating and measuring resistance in each layer with high precision and ease of use.

Layer-Specific Measurements with the RM2610 System

The RM2610 enables detailed analysis of electrode resistance by:

- Separating composite and interface resistance

- Delivering reproducible data through simple, efficient operation

- Offering intuitive software suited for both R&D and production environments

This approach gives researchers greater visibility into the electrical properties of electrode materials during development, not just after full cell assembly.

Fig. 2. Hioki Electrode Resistance measurement system RM2610

Analyzing Conductive Additives

Acetylene Black Case Study

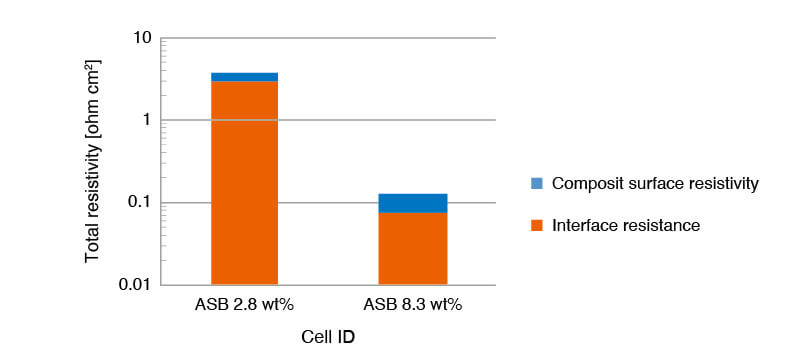

To demonstrate the RM2610's capabilities, researchers compared two electrode sheets with different concentrations of acetylene black (ASB).

- Sheet A: 2.8% ASB

- Sheet B: 8.3% ASB

The RM2610 measured composite and interface resistances for both samples (see Fig. 3).

Results:

- The interface layer contributed the majority of total resistance in both samples.

- The 8.3% ASB sheet showed significantly lower total resistance.

These findings highlight the importance of optimizing not just the active material, but also the contact surface between layers to reduce resistance.

Fig. 3. Resistance comparison: 2.8% vs. 8.3% ASB electrode sheets, measured with Hioki’s RM2610

How the RM2610 Captures Layer-Level Resistance

The RM2610 system is designed for ease of use, requiring minimal setup. Users simply prepare the electrode sheet, align the probes, and launch the measurement software. The system automatically analyzes resistance by layer and presents the results in an intuitive format, making it suitable for both research labs and production environments.

How Lower Resistance Impacts Battery Performance

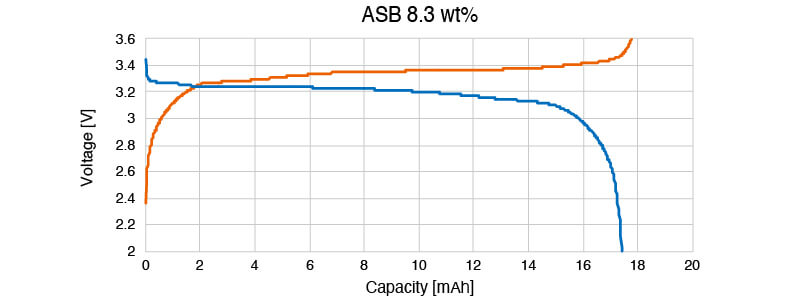

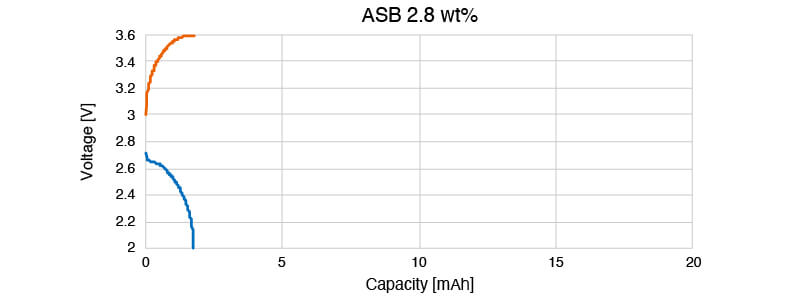

As mentioned above, measuring both composite and interface resistances with the RM2610 showed that Sheet, with a higher ASB content (8.3%), exhibited significantly lower total resistance (Fig. 3). When these electrodes were then assembled into battery cells and subjected to charge-discharge testing, the lower-resistance Sheet B cell delivered superior performance (see Fig. 4), including increased discharge capacity and reduced voltage drop under high current load.

Fig. 4. Comparison of resistance and performance between low and high ASB electrode sheets

These findings confirm a direct relationship between internal resistance and battery efficiency: reducing resistance enhances energy output and charging behavior—two key priorities in modern battery design.

Moreover, performing resistance measurements early in the development process offers long-term value. Layer-specific insights enable engineers to optimize materials for greater energy density, accelerate charging by minimizing internal losses, and improve production consistency by detecting material variability early. This also contributes to a longer battery lifespan by reducing heat buildup and mechanical degradation over repeated cycles. Understanding how each layer contributes to total resistance equips developers with actionable data to make informed design and material choices from the outset.

Empowering Battery Innovation with Better Measurement

Electrode sheet resistance is a key indicator of lithium-ion battery performance—but only when measured accurately and at the layer level. The Hioki RM2610 provides a simple, reliable, and high-resolution solution for measuring composite and interface resistance. It enables battery developers to accelerate R&D, reduce performance risks, and improve product consistency.

To explore how the RM2610 can support your next project or discuss your measurement needs, visit the product page or contact us for a demo.