Withstand voltage testing

Why are withstand voltage tests important and what are the test methods?

Withstand voltage testing is used to check whether a given electrical product or part provides sufficient dielectric strength (i.e., insulation strength) for the voltages to which it may be exposed. Three locations are tested:

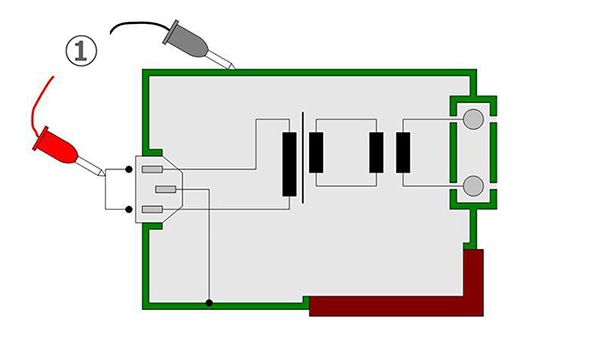

1. Between the power supply line and the grounded enclosure (to verify the dielectric strength of the basic insulation of devices such as Class 1 devices with protective grounding)

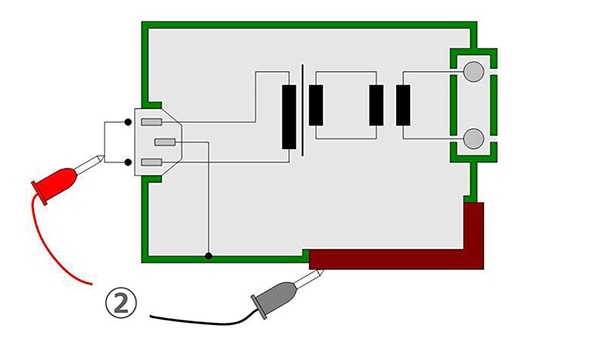

2. Between the power supply line and any ungrounded enclosure (to check the dielectric strength of double or reinforced insulation; this step is applicable to both Class 1 and class 2 devices)

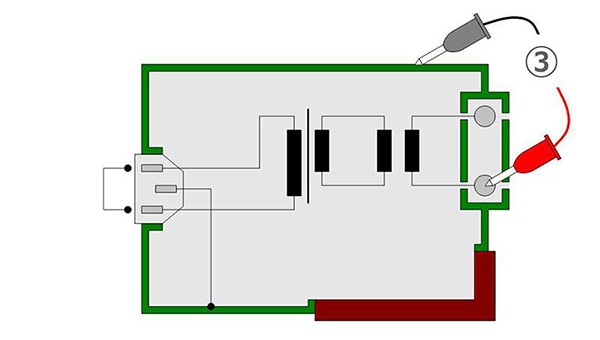

3. Between the enclosure and isolated connections (to verify that the connections are electrically isolated as a way of checking basic insulation; this step applies to devise with isolated connections)

See product lineup of Hioki electrical safety analyzers.

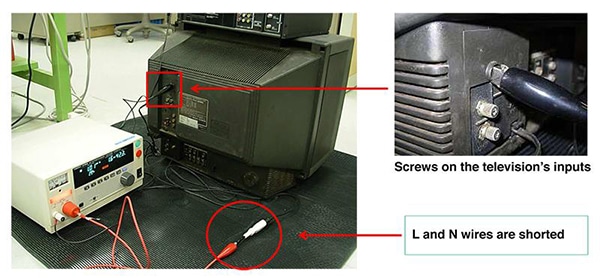

Example of withstand voltage testing

These example connections apply to a television that is being subject to withstand voltage testing. The power supply’s L and N wires are shorted and connected to the withstand voltage tester’s high-voltage terminal (red). The screws on the television’s inputs are connected to the tester’s low-voltage terminal (black).

How to determine the appropriate withstand voltage test voltage and requirements of withstand voltage testers

According to the Japanese Industrial Standard JIS C 1010-1:2014, which stipulates the safety requirements for electrical equipment for measurement, control, and laboratory use, the test voltage used by a withstand voltage tester is based on the main power supply’s specifications as follows:

(1) The supply voltage of the device being tested (for example, 100 to 240 V AC, etc.)

(2) The overvoltage (measurement) category of the device being tested (for example, CAT II, CAT III, etc)

(3) Tables provided as part of the standard

Withstand voltage testers must be able to apply the test voltages described in the standard and to measure the breaking current. They are also subject to requirements such as the following as imposed by standards and laws:

• The voltmeter precision must be JIS Class 1.5 or greater.

• The output capacity must be at least 500 VA (referring to the capacity of the transformer used in the output voltage source).

• The short-circuit current must be 200 mA (referring to the specifications of the transformer used in the output voltage source).

• The instrument must gradually increase output to the test voltage (referring to the method used to raise the output voltage).