SUPER MEGOHM METER SM7110

Rapid 6.4ms Super Megohm and Low Current Testing

The Hioki SM Series Super Megohm Meters are high resistance and ultra low current inspection devices with a 0.1 fA resolution to offer precise testing on production lines. The SM7110 is designed for use in evaluating and testing the performance of electronic components used in products such as smartphones and hybrid vehicles, and supports measurement voltage output of up to 1000 V.

Key Features

- 300 times better noise resistance

- Max. 1000 V output : SM7110

- Max. 2 × 10^19 Ω display

- Min. 0.1 fA resolution

- Built-in EXT I/O, RS-232C, GP-IB and USB

- Flexible, Multipurpose Design, High Resistance Meter/Electrometer/Picoammeter/IR Meter

- Measure resistance of materials by combining with optional electrode

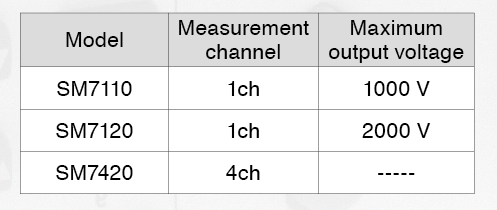

Model No. (Order Code)

| SM7110 | 1 ch, 1000 V output |

|---|

Flexible, Multipurpose Design SUPER MEGOHM METER

Includes all the following functions:

• Electrometer

• Picoammeter

• IR Meter

1000V / 1*10^19 Ω Display

Perfect for EVs and other high-voltage applications

Improved high voltage resistance and isolation performance in components are essential to meet the demands for high efficiency in recent years for applications such as automotive parts and wearable devices.

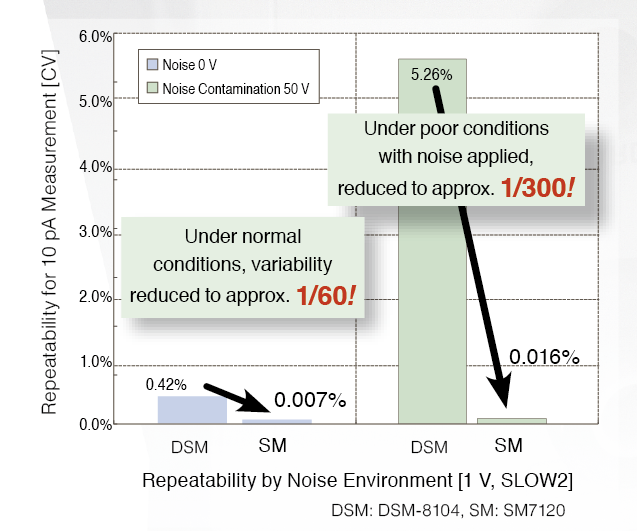

1/60 Variability, 300x Noise Resistance

Stability (repeatability) against power supply noise and external noise has improved dramatically due to a combination of new Super Megohm floating circuitry and triaxial connectors.

Variability in normal usage environments is reduced to 1/60 compared to previous models, and to 1/300* in conditions where 50 V noise is applied.

Min. 6.4 ms High-Speed Inspection

6.4 ms = 4.1 ms measurement + 2.3 ms contact check

Achieve high-speed measurement with an inspection time (from TRIG input to INDEX output) of 6.4 ms when contact checks that are essential for mass production inspections are included, and 7.0 ms when comparator measurement is included.

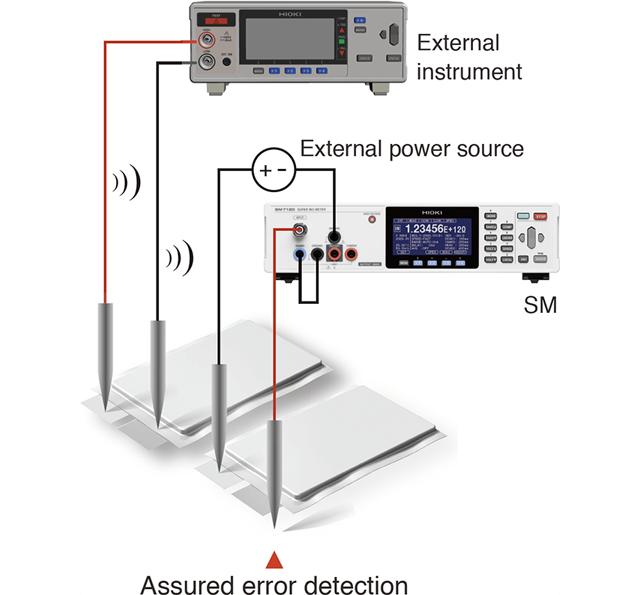

High-Performance Contact Checks

[Low capacity contact checks]

The SM7110/SM7120 is equipped with contact checks that can identify low-capacity capacitors of only a few pF as well as measured objects with a small capacitance.

(Reference value: 0.1 pF to 99.99 pF)

[2-band selection]

As with battery production lines, select the frequency for contact checks to prevent the minute check signals on site with multiple various measuring instruments from getting crossed.

These two contact checks can also be used in picoammeter mode with an external power supply. These are high-performance contact checks that prevent unnecessary retries and excess detection due to the effects of an external power supply, and that also prevent takt reduction and worsening yield ratio.

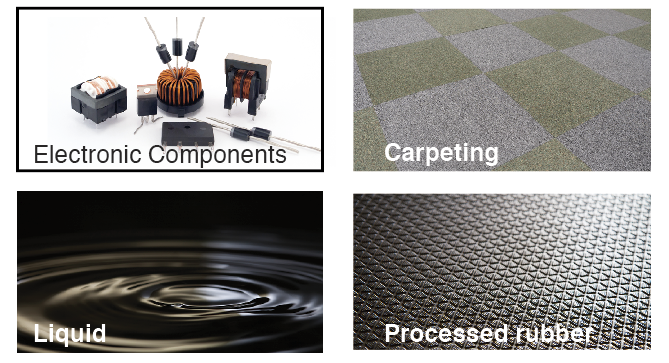

Electrodes for a Variety of Materials and Uses

• Electronic components

• Liquid

• Carpeting

• Processed rubber

Basic specifications

| Number of channels | 1 ch | |||||

|---|---|---|---|---|---|---|

| DC current measurement | 20 pA range (0.1 fA resolution), Accuracy: ±(2.0 % of rdg. +30 dgt.) 200 pA range (1.0 fA resolution), Accuracy: ±(1.0 % of rdg. +30 dgt.) 2 nA range (10 fA resolution), Accuracy: ±(0.5 % of rdg. +20 dgt.) 20 nA range (100 fA resolution), Accuracy: ±(0.5 % of rdg. +10 dgt.) 200 nA range (1 pA resolution), Accuracy: ±(0.5 % of rdg. +10 dgt.) 2 μA range (10 pA resolution), Accuracy: ±(0.5 % of rdg. +10 dgt.) 20 μA range (100 pA resolution), Accuracy: ±(0.5 % of rdg. +10 dgt.) 200 μA range (1 nA resolution), Accuracy: ±(0.5 % of rdg. +10 dgt.) *2 mA range (1 nA resolution), Accuracy: ±(0.5 % of rdg. +30 dgt.) (1) Measurement speed SLOW2 (internal integration time 13PLC) (2) At a temperature of 23 °C ±5 °C with humidity of 85% rh (3) 2 mA range (Measurement speed FAST only) |

|||||

| Resistance measurement capabilities | 1 × 10 ^3 Ω to 2 × 10 ^19 Ω Note: Resistance measurement accuracy is defined by the current range accuracy and voltage setting accuracy. |

|||||

| Setting voltage range (Accuracy) |

0.1 to 100.0 V, 100 mV resolution, Accuracy: ±0.1 % of setting ±0.05% f.s. 100.1 to 1000 V, 1 V resolution, Accuracy: ±0.1 % of setting ±0.05% f.s. |

|||||

| Current Limiter | 0.1 to 250.0 V: 5/ 10/ 50 mA, 251 to 1000 V: 5/ 10 mA, to 2000 V:1.8 mA | |||||

| Measurement time setting | Delay: 0 to 9,999 ms | |||||

| Functions | Comparator, averaging, self-calibration, jig Capacity open correction, cable length correction, surface resistivity, volume resistivity, voltage monitor, contact check | |||||

| Program function | 10 types of discharge, charge, measure and measurement sequence discharge patterns can be programmed. | |||||

| Display | LCD (8 lines of 30 characters), with backlight, High voltage warning indicator | |||||

| Interfaces | USB, RS-232C, GP-IB, EXT I/O (NPN/PNP can be switched) | |||||

| Power supply | 100 to 240V AC , 50/60 Hz, 45 VA | |||||

| Dimensions and mass | 330 mm (12.99 in)W × 80 mm (3.15 in)H × 450 mm (17.72 in)D, 5.9 kg (208.1 oz) | |||||

| Included accessories | Power cord ×1, Instruction manual ×1, EXT I/O male connector ×1, Short plug ×1 | |||||

Measurement Leads (6)

1 m (3.28 ft) length

1 m (3.28 ft) length

1 m (3.28 ft) length

1 m (3.28 ft) length

3 m (9.84 ft) length

3 m (9.84 ft) length

Measurement electrodes (9)

The Z5010 Conversion Adapter is required to connect the SM7110 to a measurement electrode.

・Electrode checker dedicated for SM9001

・Not CE marked

Humidity sensors (1)

1.5 m (4.92 ft)

PC communication (2)

2 m (6.56 ft) length

9 pin - 9 pin, cross, 1.8 m (5.91 ft) length

Others (4)

0.1 m (0.33 ft) length

・Connection between electrode / shielding box and SM7110, SM7120

・Not CE marked

- How to Use the SM7420 for Simultaneous Multi-Point Insulation Resistance

- Surface and Volume Resistivity Measurement of Insulation Materials

- Insulation Performance Testing of Insulating Materials: An Essential Process for Electric Vehicles

- The Role of Separators in Lithium-ion Batteries and Shutdown Testing

- AEC-Q200-compliant evaluation of the temperature of electronic components

- Use of the SM7110 to Evaluate I-V Characteristics of Photodiodes in Optical Communications

- Measuring the Surface Resistance of Industrial Materials

- Detection of Insulation Defects in Lithium-ion Batteries