POWER ANALYZER PW6001

V3.06 Feb 16, 2024

- If you are unable to download software, please check the following:

- Please register a my HIOKI account and then use it to log in to the my HIOKI service.

- Product firmware (product upgrades) and computer application software can only be downloaded for products you have registered on the my HIOKI service.

| Firmware (6001V306.zip) | |

|---|---|

| Procedure on how to update the firmware (PW6001FirmwareUpdateProcedures.pdf) |

Version upgrade should be conducted by a qualified technician familiar with the functions and operations of model PW6001.

If you are uncertain as to how to proceed, please contact your local Hioki distributor for assistance.

・All software provided here is freeware and the best version currently available.

・If the problems or errors during this download and install lead to malfunction, please contact your dealer or Hioki representative.

・The ownership, intellectual right and all other associated rights relating to the software provided here belong to Hioki E.E. Corporation.

If you have read and understand the information above and wish to proceed then please download the designated files.

As for version upgrade procedure, please download ”PW6001FirmwareUpdateProcedures.pdf” which describes the preparation and procedure for upgrading firmware after downloading the files.

Precaution when updating firmware:

・To conduct the version upgrade, USB memory stick is required.

・During the version upgrade process, don’t turn off the power to the PW6001 or don’t remove the USB memory stick from the slot. Turning power off will result in failure to upgrade the PW6001, and the instrument must be returned to the Hioki factory for repair.

Firmware for the Model PW6001

The current newest firmware version is V3.06. A version upgrade is highly recommended if you are running older firmware.

Before you proceed

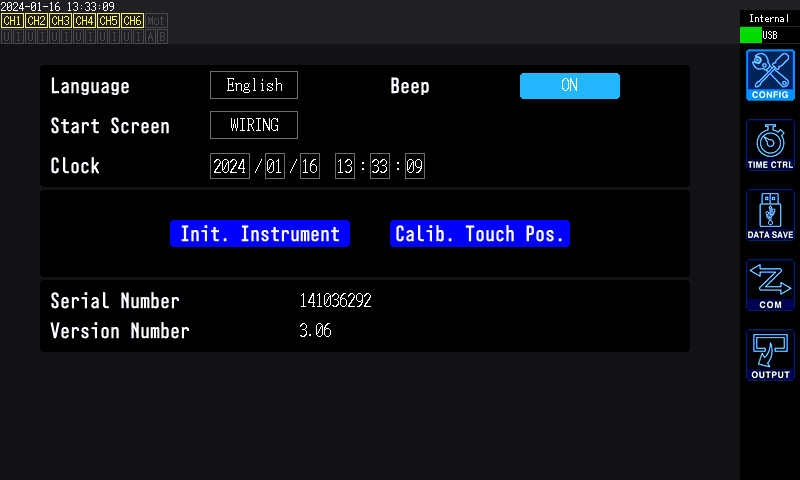

Confirm the version number in the ‘CONFIG’ screen by pressing “SYSTEM” key.

Version Upgrade History

V3.06 (February 2024) Latest Version

1. Enhancement

-1. Updated Simplified Chinese font data.

V3.05 (July 2023)

1. Enhancement

-1. The touch position detection range has been expanded when adjusting the touch position of the touch panel.

V3.04 (June 2023)

1. Added functions

-1. Compatible with current sensors with 2A rating (CT6830 AC/DC Current Probe to be launched in autumn 2023).

V3.03 (September 2019)

1. Fixed bugs

-1. Boot key reset while using a 2000A rated current sensor results in an abnormal measurement value.

-2. May be unresponsive during long time period of communication.

2. Added functions

-1. Added a function to display and control the phase zero adjustment value of the motor option.

-2. Added communication command to set and confirm the phase zero adjustment value for motor options.

-3. Added the phase zero adjustment value to the data reflected when reading the setting file.

3. Enhancements

-1. Changed the calculation method of the integrated power SUM value in multi-phase wirings in order to match to integration in buying and selling power. Power analyzer splits WP to WP+ and WP- according to the sign of the instantaneous SUM value.

-2. Improved the phenomenon that causes the D/A output waveform to become abnormal when performing a setting change operation such as range switching during D/A waveform output mode.

-3. There were current sensors of the same type but could not be mixed in one wiring due to the difference between the old and new connectors. Now, these sensors can be mixed in one wiring. The type is determined by "Rating" and differentiation between "AC sensors or AC/DC sensors".

-4. Changed LPF setting to OFF when PWM mode is selected in quick configuration function.

V3.02 (October 2018)

1. Fixed bugs

-1. When loading the setting file set for numerical synchronization, measurement data is not transferred to the master side.

-2. Address setting is not reflected until GPIB address is changed and power is turned on again.

-3. Corrected argument range of ": GPIB: ADDRess" command to 0 - 30

2. Added functions

-1. Added rotary knob 10 pulse, 50 pulse button to remote control screen.

V3.01 (November 2017)

1.Fixed bugs

-1. In the D/A Monitor Screen, a discrepancy was found between the time axis settings and the plot data.

-2. If phase zero adjustment was performed over several cycles without resetting, the phase was rarely adjusted to 180°.

V3.00 (September 2017)

1.Fixed bugs

-1. Setting the startup screen to LAST and turning off the instrument while the motor option settings screen was displayed prevented the instrument from starting up normally the next time it was turned on.

-2. Touching the display while the instrument was displaying the D/A monitor screen caused the assert display to be shown and the instrument to freeze.

-3. UDF settings were not applied when a settings data file was loaded in firmware versions Ver. 1.21 to Ver. 1.23.

-4. Inputting certain types of signal while using the auto-scaling setting on the D/A monitor display caused the assert display to be shown and the instrument to freeze shortly thereafter.

-5. While averaging mode was being set to ADD, changing a particular setting cleared the harmonic status flag UCU mandatorily.

-6. Other minor bugs fixed.

2. Added functions

-1. A user-configurable zoom ratio has been added to the waveform zoom display.

-2. An auto-trigger function has been added.

-3. An event trigger function has been added.

-4. A command for switching the number of parameters shown on the custom screen has been added.

-5. An external signal synchronization function has been added.

-6. Simple settings for inductor and transformer measurement have been added.

-7. A scale display with RMS values on the Y-axis has been added to the FFT calculation results screen.

3. Enhancements

-1. Level trigger operation when the waveform recording mode is set to P-P has been corrected.

-2. It is now possible to use symbols that could not previously be used in filenames (_^$!#%&-@’()~`{}).

-3. Other enhancements.

V2.00 (August 2016)

1.Fixed bugs

-1. If the instrument received a command of a particular length via LAN, the communications failed subsequently.

-2. The operations in the following order with the synchronization control disabled caused the instrument to freeze: (1) configure the data update rate setting to 10 ms, (2) set to SLAVE MEAS (although the synchronization should have been disabled), and (3) display the COMMON setting screen.

-3. Changing the FFT settings of the slave instrument during the numerical synchronization caused an interruption of the integration in progress.

-4. If an AC/DC current sensor with a rated maximum current of 1 kA was connected to Probe 1, the integration mode could not be configured to DC.

-5. Other minor bugs fixed.

2. Added functions

-1. Added the D/A monitor graph screen.

-2. Added the X-Y plot screen.

-3. Added the FTP server function.

-4. Added the function that improves the measuring accuracy of phase difference in a high-frequency band.

-5. Communication via LR8410Link support

-6. Waveforms can now be saved in a binary format.

-7. Added the command that obtains measured values in the internal memory.

-8. Sensors with a rated maximum current of 5 A are now connectable.

-9. FFT analysis results can now be saved in a CSV format.

3. Enhancements

-1. It is now possible to configure the VT ratio and the CT ratio settings to 0.00001 at a minimum.

-2. It is now possible to load setting data that were created by using an instrument with an earlier version of the firmware installed and data including different sensor configuration.

-3. It is now possible to configure the sensor characteristics correction angle in increments of 0.01°.

-4. For the motor setting, the limitation that the pulse number shall be a multiple of half of the pole number is now removed.

-5. Reciprocal numbers of periods (frequency) between X and Y cursors are now additionally displayed when the cursors are used on the WAVE screen.

-6. Other enhancements.

V1.23 (January 2016)

1.Fixed bugs

-1. Changing zoom factor on the zoom screen by turning the rotary knob quickly before a displayed waveform reached the zoom area while waveform storage was in progress in real-time mode caused the instrument to freeze.

-2. Entering a value expressed as a decimal fraction preceded by two or more zeros, for example 000.951, 0035.852, and 00147.5, in the scaling (scale value) field for speed on the motor screen caused the alert “assert” to be displayed, resulting in the instrument freezing.

-3. The operations in the following order caused the alert “assert” to be displayed, resulting in the instrument freezing.

(1) Turn off the instrument, leaving it in any one of the 3-phase connection modes.

(2) Turn on the instrument.

(3) Change the connection mode to any one of the single-phase connection modes.

(4) Touch the U button on the Wave screen.

-4. Selecting a waveform by pressing the U or I button after selecting a channel of the slave on the Zoom screen by operating the channel keys during waveform synchronization caused the alert “assert” to be displayed, resulting in the instrument freezing.

-5. Performing integration while the auto-saving was activated with the screen displayed in English or Chinese, and then, performing an operation such as screen change after the elapse of a certain period of time caused the instrument to freeze.

-6.Other minor bugs fixed.

V1.22 (December 2015)

1. Fixed bugs

-1. In some cases while using Model PW6001-04 or PW6001-14, changing the connection mode to two circuits of 3P3W2M failed, resulting in an error.

V1.21 (October 2015)

1. Fixed bugs

-1. When the motor scaling value was set to a non-integer value, the motor waveform’s CSV output values were less than the actual values.

-2. When using the exponential mean and SLOW settings, there was a period of time during which invalid measured values were displayed immediately after the setting was changed.

-3. Saving a waveform while the sampling rate was set to 10 kHz caused the motor waveform’s sampling frequency to be displayed as 1 MHz.

-4. When averaging was enabled, in some cases the range was continually changed by the auto-range function, with the result that the range was not fixed (the measured value display showed “-------”).

-5. PW6001 ends up stopped by certain operations and communication command.

-6. Other minor bugs fixed.

2. Added functions

-1. User-defined calculation function (UDF)

-2. FFT calculation function

-3. Waveform cursor measurement function

-4. Waveform zoom function

-5. HTTP server function

-6. Screenshot display function

-7. Chinese language support

3. Enhancements

-1. The motor RPM scaling upper limit value has been changed from 9999.99 to 99999.9.

-2. The motor pole count upper limit value has been changed from 98 to 254.

-3. The file segment count upper limit used when outputting data has been changed from 20 to 100.

-4. Other enhancements.

V1.02 (March 2015)

Initial release.