Calibration and Adjustment

Calibration

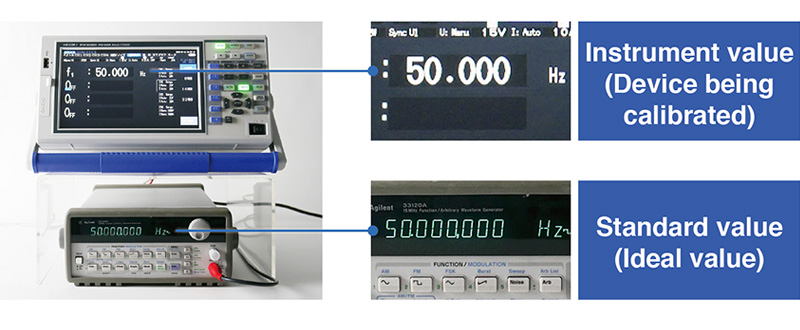

Because it verifies the condition of an instrument, calibration is like a health checkup. Specifically, the process involves checking the condition of an instrument at a particular point in time by comparing the ideal value indicated by a standard and the value indicated by the instrument being calibrated.

Upon receiving a calibration request, we perform Standard Calibration.

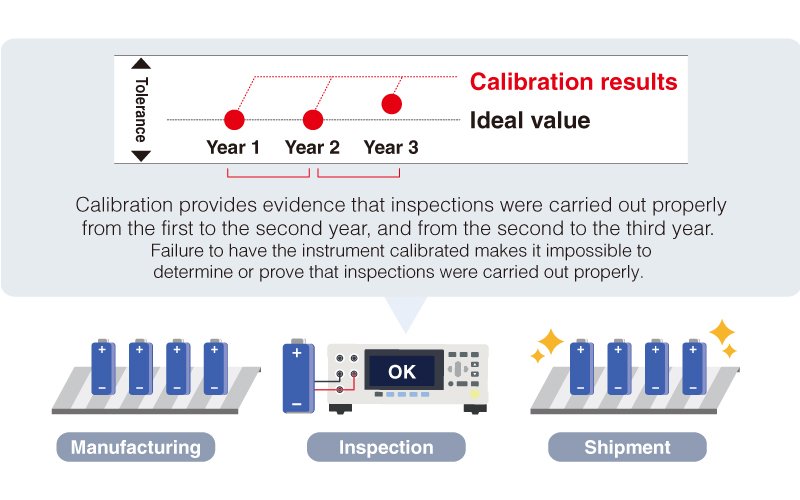

Using uncalibrated instruments may lead to critical errors

Even high-quality measuring instruments may produce deviations from ideal values depending on usage and environmental conditions. Calibration helps identify these deviations, enabling adjustment or repair as needed. Continued use without calibration may result in measurements falling outside acceptable ranges. Periodic calibration and documented confirmation of values serve as evidence that proper inspections have been performed.

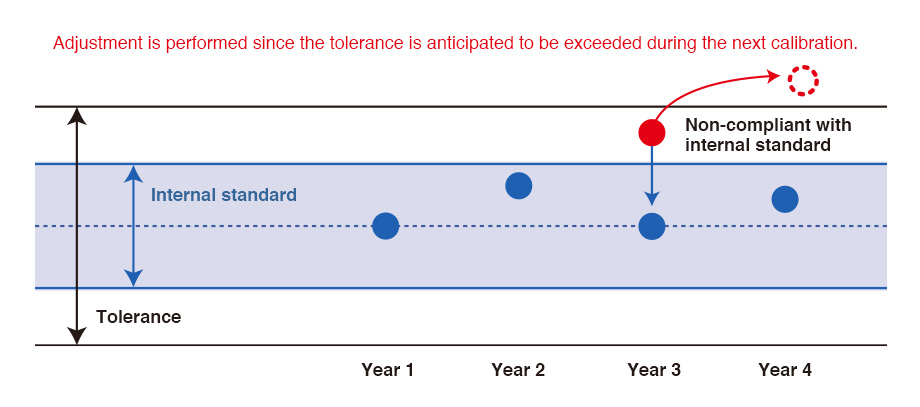

Adjustment

All calibration values are adjusted to meet Hioki’s inspection standards.

If calibration values fall outside Hioki’s inspection standards

All calibration values will be adjusted to meet Hioki’s inspection standards, reducing the risk of future deviations beyond the allowable range.