IN-CIRCUIT HiTESTER 1220

High Performance Populated Board Testing with Expansion Capabilities

Hioki PCB and substrate inspection equipment leverages our core competency in high precision component testing. In populated board production settings where improving productivity is key, even small time losses are unacceptable. The 1220 series provide a single solution for jobs that previously required multiple measuring instruments, featuring a compact PCI bus that delivers a dramatic speed boost of 150%.

Key Features

- Extensive test functionality in a single tabletop box (1220-50)

- Detection of electrolytic capacitor and IC reverse insertion (optional feature)

- Macro testing for increasing test efficiency

- Extensive range of system configurations

Model No. (Order Code)

| 1220-50 | Desktop model |

|---|---|

| 1220-51 | Off-line model |

| 1220-52 | Space-saving model |

| 1220-55 | In-line model |

FULL Lineup

Available in desktop, space-saving, and inline models to accommodate the full range of site needs.

LED color recognition and brightness detection

The 1220 incorporates a power source unit, allowing it to perform mounting tests and LED tests with a single fixture.

This single-device solution not only reduces cycle times, but also aids in post-testing analysis due to the ability to consolidate data.

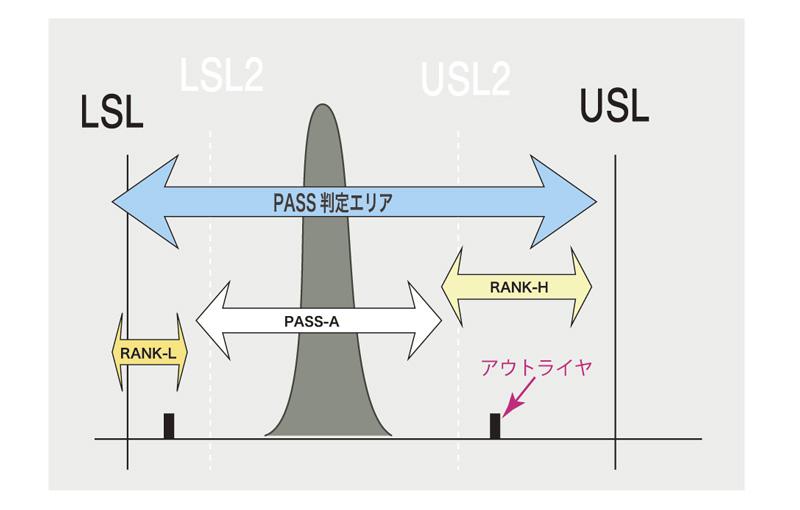

For people considering parts average testing (PAT)

The 1220 brings the PAT process to testing of printed circuit boards and adds a rank detection function for ICT in order to improve quality.

A rank detection flag is added to outliers (abnormal values) that are separated from the parent population. The decision of whether to perform rank detection can be added on a component-by-component basis.

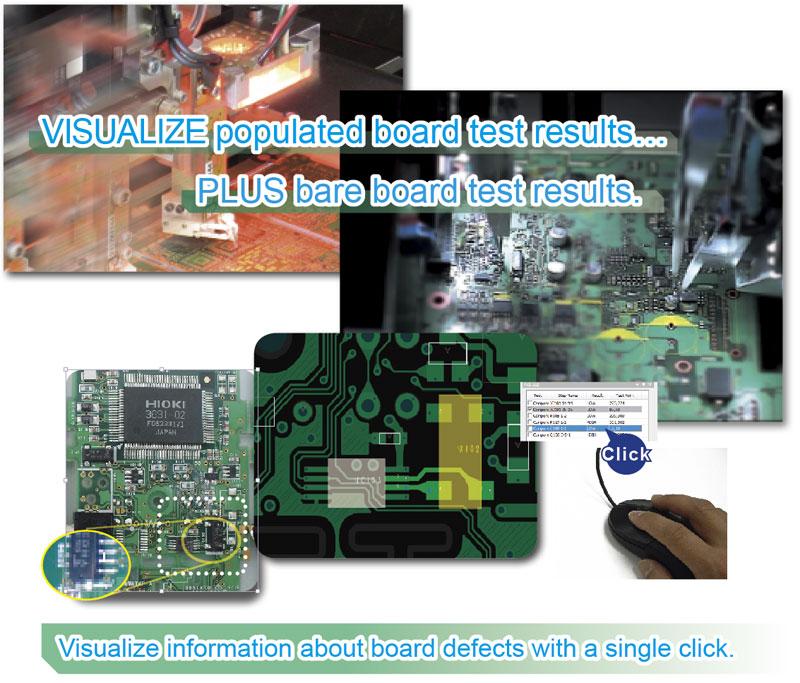

Point information view (UA1782)

Where are test fixture pins indicating fail results contacting the board?”

It's easy to identify the locations of defective pins and to search for components by using the Point Viewer while testing is underway or the while the Fail Viewer UA1782 is offline.

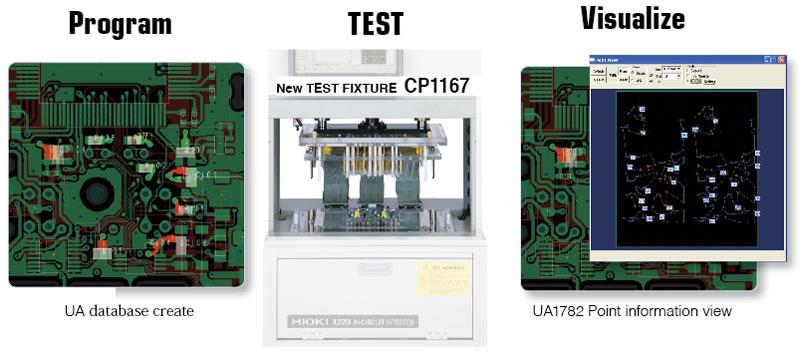

[Program,Test,Visualize] Populated Board Electrical Testing System

Hioki can prepare populated board testing system benchmarks if provided with the three types of data listed below.

[Program] FIT-LINE UA1780

[Test] IN-CIRCUIT HiTESTER 1220

[Visualize] FAIL VISUALIZER UA1782

When testing populated boards, it's essential to create accurate data, measure boards accurately, and identify defective locations accurately.

Specifications Overview

| 1220-50 | 1220-51 | 1220-52 | 1220-55 | |||

| Test types and ranges | Round-robin short/open, Component test | |||||

| Macro test : 10 Ω to 10 MΩ (Impedance) | ||||||

| Resistance : 400 μΩ to 40 MΩ | ||||||

| Capacitance : 10 pF to 400 mF | ||||||

| Coils : 1 μH to 100 H | ||||||

| Diodes, transistors : 0 V to 25 V | ||||||

| Zener diode : 0 V to 25 V (Option: 25 V to 120 V) | ||||||

| Digital transistors : 0 V to 25 V | ||||||

| Photo coupler test function : 0 V to 25 V | ||||||

| Capacitor reverse insertion detection (Option), IC reverse insertion detection (Option) | ||||||

| Number of Max. test points | Max. 2,176 pins (3 expansion racks), Standard: 128 pins |

Max. 2,176 pins (3 expansion racks), Standard: 320 pins |

Max. 1,536 pins (2 expansion racks), Standard: 320 pins |

Max. 2,176 pins (3 expansion racks), Standard: 320 pins |

||

| Can be expanded in blocks of 64. | ||||||

| No. of Max. test steps | 10,000 steps | |||||

| Measurement time | Round-robin short/open: From approx. 0.8 ms/pin Component: From approx. 0.9 ms/step |

|||||

| Measurable board dimensions |

-- | 390 mm (15.35 in)W × 300 mm (11.81 in)D | ||||

| Power supply | 100 V AC (±10%) (Specify at time of order), Power consumption: 700 to 1000 VA | |||||

| Dimensions and mass | 200 mm (7.87 in) W × 325 mm (12.80 in) H × 298 mm (11.73 in) D, 10 kg (352.7 oz) | 1030 mm (40.55 in) W × 1470 mm (57.87 in) H × 710 mm (27.95 in) D, 240 kg (8465.6 oz) | 655 mm (25.79 in) W × 1610 mm (63.39 in) H × 705 mm (27.76 in) D, 220 kg (7760.1 oz) | -- | ||

Options (2)

64 pins/cable