Electrical safety standards, laws, and regulations

Hioki electrical safety testers and applicable standards, laws, and regulations

National electric safety standards have been developed based on the IEC 61010 standard, including the following: EN 61010 (Europe), JIS C 1010 (Japan), and GB 4793 (China). In some cases, individual countries have augmented the IEC standard with their own safety-related provisions. Hioki’s electrical safety testers (withstand voltage testers, insulation resistance testers, protective continuity testers, and leakage current testers) comply with IEC 61010-1, JIS C 1010-1, and other applicable standards, laws, and regulations.

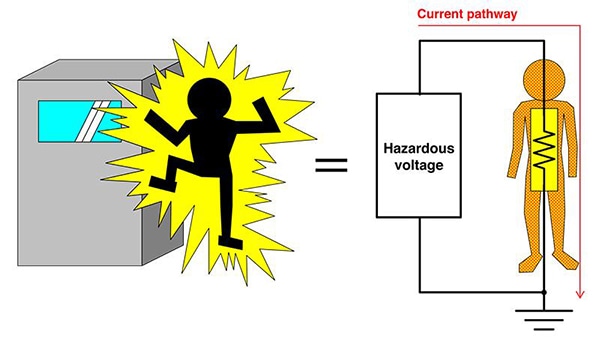

Electric shock and associated countermeasures

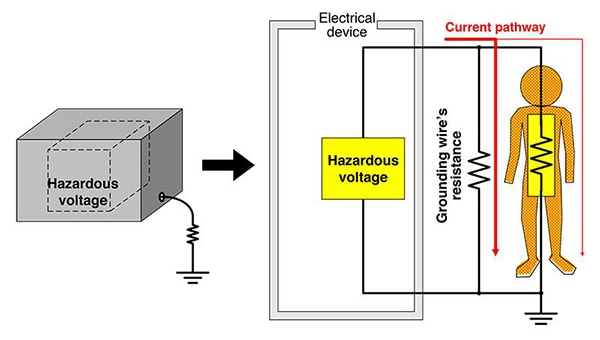

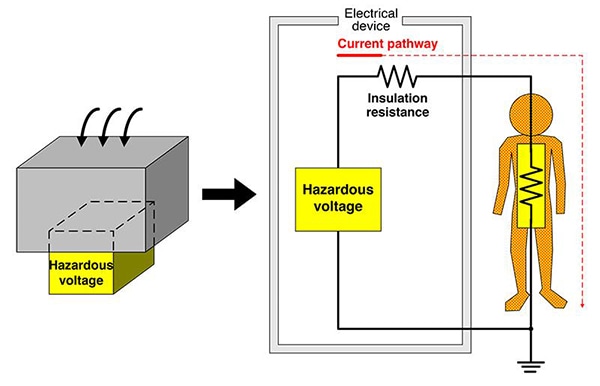

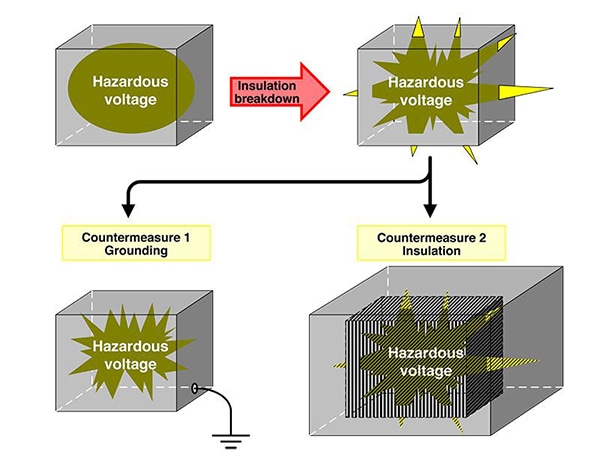

An electric shock occurs when a person comes into contact with an electrical device operating at a hazardous voltage without adequate protection against electric shock to form a current pathway, causing current to flow through the person’s body. In designing electrical devices, there are two ways to address the risk of electric shock. The first is to route the current elsewhere by grounding the device, and the second is to prevent the current from leaving the device by insulating it.

Countermeasure 1 consists of creating a circuit with greatly lower resistance than the human body (in other words, a grounding wire) so that most current flows to that circuit. In this case, the grounding wire’s resistance must be approximately 0 Ω.

Countermeasure 2 consists of increasing the insulation resistance to the point that no voltage occurs between the device’s internal components and its enclosure or other external surface.

See product lineup of Hioki electrical safety analyzers.

Classes of electric devices

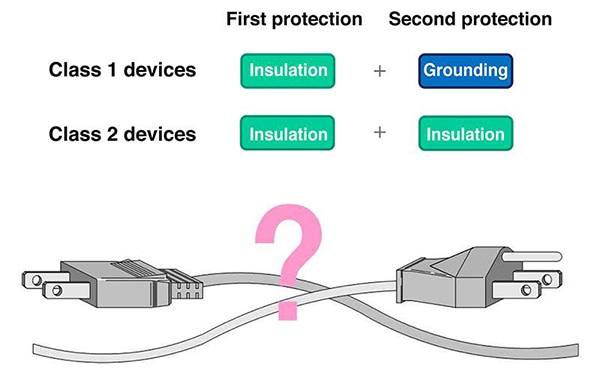

The standards assign one of two classes to electric devices depending on how they implement the second layer of protection. Devices that use grounding to implement the second layer of protection are known as Class 1 devices, while those that offer additional protection with insulation are known as Class 2 devices.

How do I check a device’s electric shock protection and what are the test methods?

To check grounding: Protective continuity testing

To check insulation: Withstand voltage, insulation resistance, and leakage current testing.