Why is it Important to Measure Battery's Internal Resistance?

There are two main purposes for measuring the internal resistance of a battery.

What is the internal resistance of a battery?

Internal resistance is one of the parameters that indicate a battery's ability to carry current.

When the value of internal resistance is low, the battery is able to carry a significant amount of current. On the other hand, a battery with high internal resistance can only carry a small amount of current.

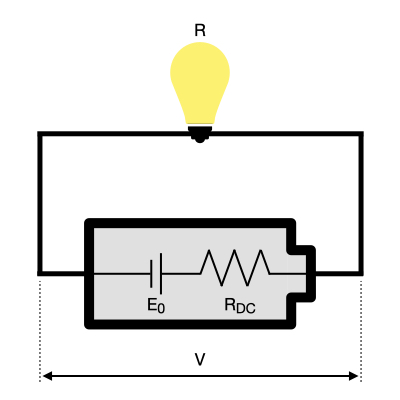

Fig.1 shows an example of the internal configuration of a battery. Ideally, a battery's internal resistance should be zero, allowing for maximum current flow without any energy loss. In reality, however, as illustrated in Fig.1, internal resistance is always present.

Let's consider an example to illustrate this. The battery voltage is determined by the internal resistance and the output current. Suppose we have a battery electromotive force of E0=10 V. When the battery's internal resistance, RDC, is 1 Ω, and the load, R, is 9 Ω, the battery outputs a voltage of 9 V. However, if the internal resistance increases to 2 Ω, the output voltage drops to approximately 8.2 V.

In summary, internal resistance influences a battery's current-carrying capacity. The higher the internal resistance, the greater the energy loss, which is converted into "heat." This heat not only represents energy wastage but also contributes to the degradation of the battery.

Fig.1 Internal configuration of a battery

Quality Inspection during Battery Production

The first reason for measuring internal resistance is to ensure quality control throughout production. It is possible to determine the quality of a battery by measuring its internal resistance.

However, how many ohms of internal resistance would be considered a high-quality battery?

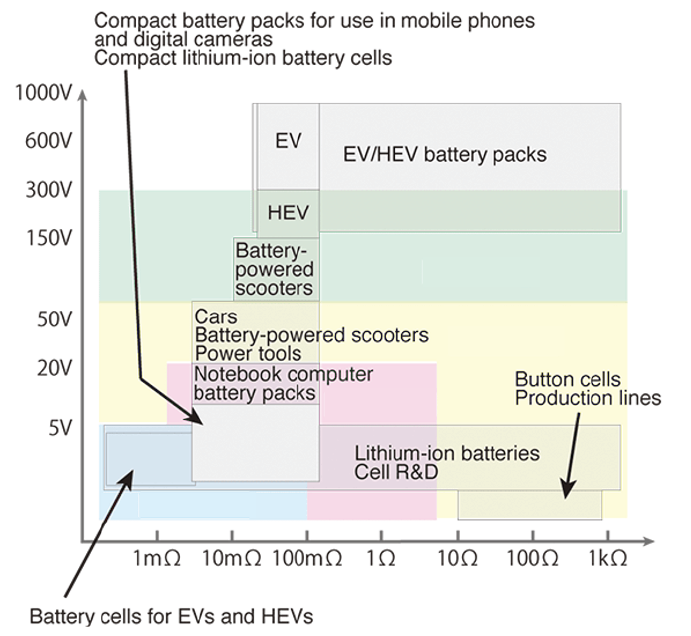

Well, it depends on the type of battery. As shown in Fig. 2, depending on the material, structure, size, voltage, and other factors, different types of batteries have varied internal resistance levels. Fig. 3 illustrates how some batteries have several mΩ, while others have over 1 kΩ of internal resistance.

Fig. 2 Examples of different types of batteries

Fig. 2 Examples of different types of batteries Fig.3 Batteries' internal resistance and voltage

Fig.3 Batteries' internal resistance and voltage

Determination using internal resistance allows a consistent battery quality that meets the specifications. It plays an important role in maintaining the quality of a battery during production

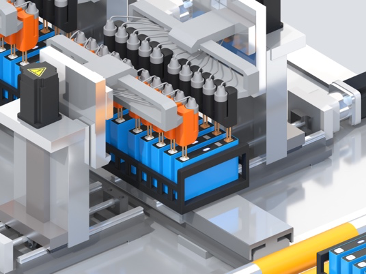

Cells produced at the cell production factory are shipped to the module production factory after undergoing a shipping inspection.

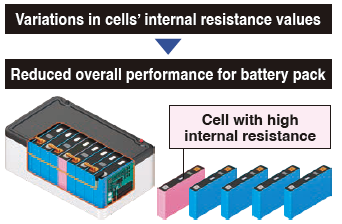

Since factors such as vibrations during shipment and even the passage of time can cause defects, batteries undergo an acceptance inspection before cells are assembled into modules and packs. It’s important that all the cells in a given battery pack have equivalent internal resistance. If one or more cells have high internal resistance or have degraded, they will become a bottleneck and limit the battery pack’s capacity.

To improve the quality of the battery pack, it is important to select cells that all have an equivalent internal resistance.

Maintenance during Battery Operation

The second reason for measuring internal resistance is for battery maintenance. The internal resistance of a battery gradually increases as it is used. The power from a battery comes from the chemical reaction between the electrolytes and the electrodes. However, over a long period of time, the chemical reaction will slow down due to rust and corrosion inside the electrodes. As the chemical reaction slows down, the internal resistance of the battery increases.

When it comes to storage batteries, such as UPS, it is critical that the batteries provide sufficient power when needed.

By measuring the internal resistance of the battery on a regular basis, a degraded battery can be eliminated.

The internal resistance of a battery is an important parameter for quality inspection during production and maintenance process.

Get the best performance out of your battery by measuring it properly.