The Complete Guide to Electrical and Temperature Measurement

In today's rapidly advancing technological world, electrical and temperature measurements have become essential for a wide range of industries and applications.

This complete guide will provide you with a comprehensive understanding of the subject.

Electrical Measurement

Electrical measurements are crucial for analyzing, monitoring, and controlling various systems.

By grasping the fundamental concepts, you can gain a deeper understanding of how electrical measurements work.

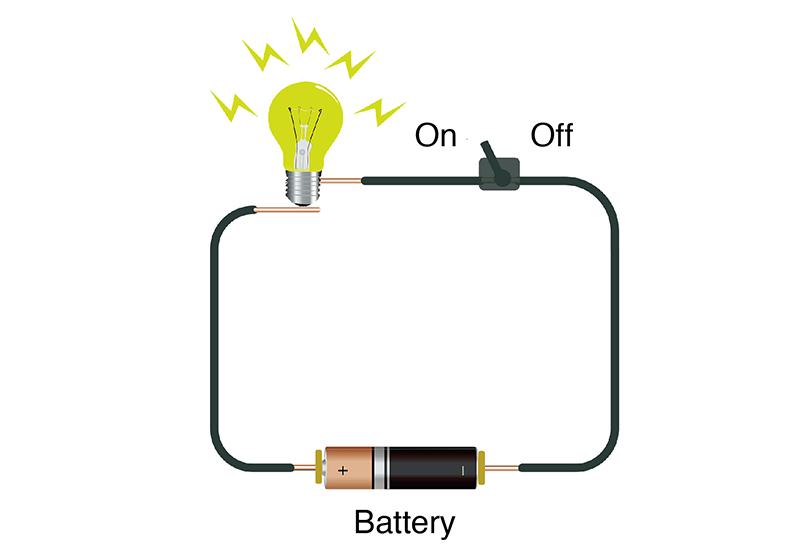

Understand the Basics of Electricity

What is Voltage?

Voltage refers to the electrical potential difference or the force that drives electric charge to flow in a circuit. It is measured in volts (V) and created through processes that involve the separation of electric charges or differences in potential energy.

What is Electric Current?

Electric current is the rate of flow of electric charge through a conductor. It is measured in amperes (A) and plays a pivotal role in assessing the performance and functionality of electrical circuits and devices.

Do you want to continuously collect current and voltage but don't know how to start? Data loggers are the perfect solution for anyone who needs to collect data from a variety of sources, including sensors, devices, and systems. For more information, please see the blog below.

What is Resistance?

Electrical resistance is the measure of opposition that a material presents to the flow of electric current. It is measured in ohms (Ω; a unit of electrical resistance) and characterizes a material's ability to impede the flow of electric charge.

What is Electric Power?

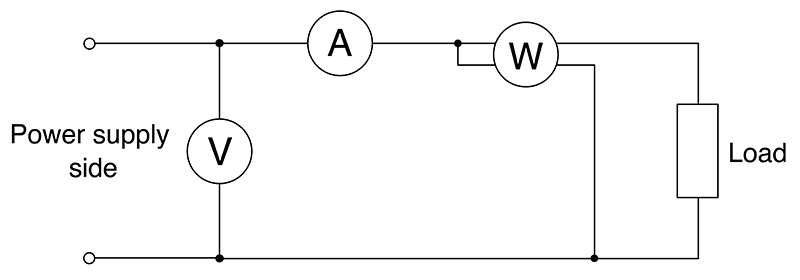

- Power measurement connections

Electric Power Definition

Electric power, measured in watts (W), is the rate of energy transfer in a circuit. It's a key factor in understanding device and system performance.

Power Equation (Formula) in Circuits

P=VI

P(watts): Electric power

V(volts): Voltage

I(amperes): Electric current

Example of measurement applications

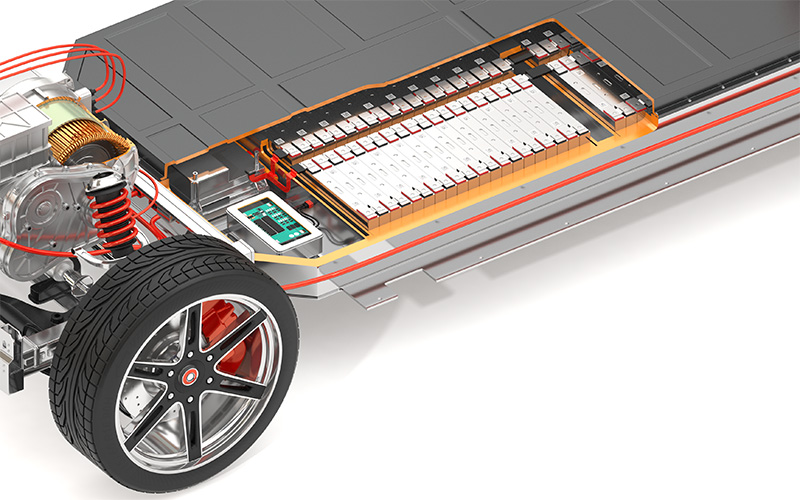

Electric Car Battery Voltage

When it comes to voltage measurement, we encounter various scenarios, such as measuring the voltage of uninterruptible power supplies, examining our power supply system, or even measuring the battery voltage in electric vehicles. The method used for measurement can vary depending on the operator's specific objectives. Therefore, when choosing a measurement method and tools, it is important to consider factors such as accuracy, range, and the specific requirements of the electrical system being analyzed.

For example, the battery voltage in electric cars is a vital metric affecting their performance and range.

Why Accurate Voltage Measurement Matters for electric vehicle battery voltage?

1. Range Estimation

Accurate voltage measurement helps estimate an EV's remaining range; reducing driver anxiety.

2. Battery Health

It provides insights into the battery's condition, allowing timely maintenance or replacement.

3. Charging Control

Maintaining the correct voltage level ensures safe and efficient charging.

4. Efficiency

Understanding the voltage-power output relationship optimizes performance and extends battery life.

Using Data Loggers

Data loggers with sensors and software enable continuous and automated voltage monitoring, aiding long-term analysis and performance optimization.

In summary, precise voltage monitoring via data loggers is critical for EV performance, range, and sustainability

You can gain an understanding of measurements using data loggers and more from the related articles below.

Physical Measurements

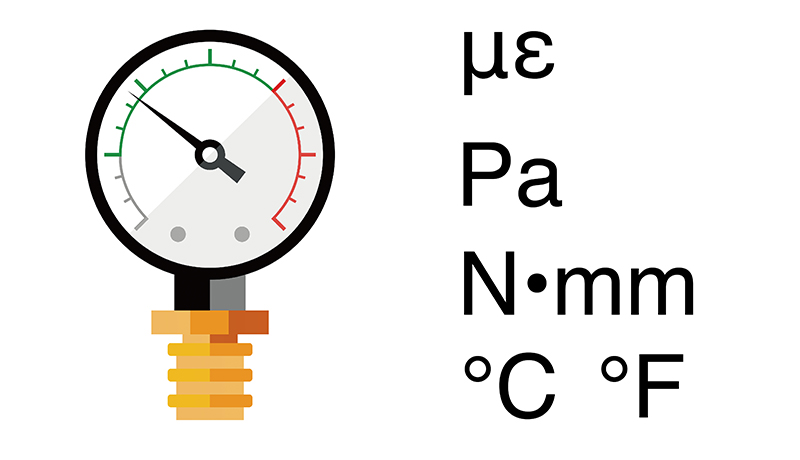

Physical measurements involve quantifying parameters such as strain, pressure, stress, and temperature to understand the behavior of materials and systems.

Also, scientists and engineers can gain valuable insights into how materials and systems respond to external forces and temperature changes.

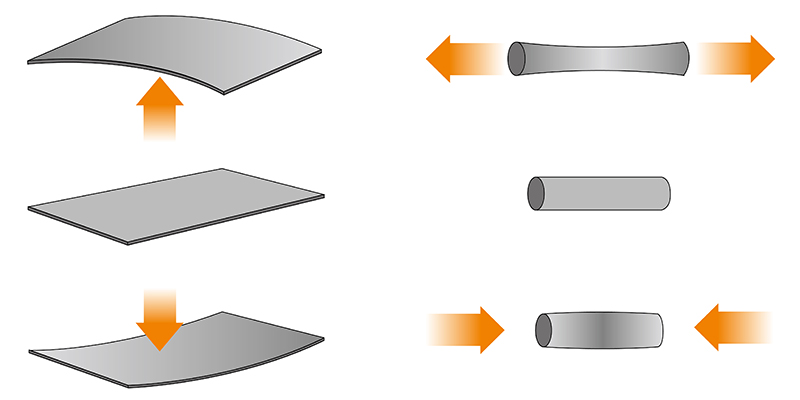

What is Strain?

Strain refers to the deformation experienced by a material when subjected to external forces or temperature changes. It is a measure of how much an object's shape has changed compared to its original form. By quantifying the amount of deformation, a material undergoes, engineers can evaluate its performance and determine its suitability for specific applications.

Sensors based on Strain Gauge Principles

Strain, which occurs when an object deforms in response to external forces, can be measured using strain gauges. Similar to measuring temperature using thermocouples, strain gauges are employed to accurately measure the deformation of an object.

Pressure Sensors

Pressure sensors utilize the principle of strain gauges to detect changes in pressure. When external pressure is applied, the spring element deforms, leading to a change in the resistance of the strain gauges. Pressure sensors find applications across various industries and play a crucial role in tasks such as process control and quality management.

Acceleration Sensors

Acceleration sensors are designed to measure the acceleration of an object. When an object experiences acceleration, it results in strain, which is detected by acceleration sensors. These sensors are capable of detecting and providing measurements of acceleration in structures, vehicles, and other systems.

Strain measurement sensors based on strain gauges are widely used in diverse fields, and they offer continuous measurements, similar to temperature and electrical characteristics. Utilizing data loggers enables effective utilization of these sensors, allowing for data analysis and reporting. Strain measurement technology is essential for quality control and improving the safety of structures in various industries.

What is temperature?

Temperature serves as a critical indicator of a material's thermal state and finds widespread application in everyday life to industrial processes. Accurate temperature measurement is indispensable for quality control, safety, and efficiency. The temperature of a substance influences its molecular motion and leads to changes in various material properties. In this section, we'll delve into the fundamentals and significance of temperature measurement, including methods using thermocouples and more.

Principles of Temperature Measurement

Temperature measurement techniques rely on various physical principles. Electrical methods, such as thermocouples and resistance temperature detectors, utilize the electrical properties of materials to determine temperature. Mechanical methods, such as bimetallic strips and liquid-in-glass thermometers, rely on the expansion and contraction of materials with temperature changes.

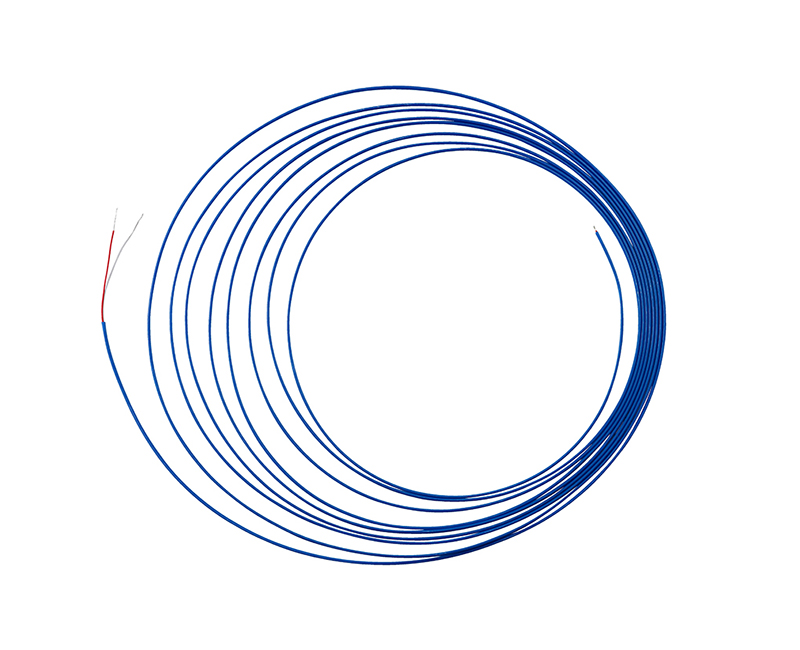

What is a Thermocouple?

Thermocouple, K type

Thermocouple, K type

A thermocouple, by definition, is a temperature sensor made up of two dissimilar metal wires joined at one end. It operates based on the Seebeck effect, where a temperature gradient generates a voltage difference, allowing it to measure the temperature of the hot junction.

How does a Thermocouple Work?

A thermocouple generates a small voltage proportional to the temperature difference between the hot and cold junctions. This voltage can be measured using specialized circuitry. Thermocouples have wide temperature ranges and are commonly used in various industries for temperature measurement.

The working principle of a thermocouple is based on the Seebeck effect, which occurs when two dissimilar metals are joined together and subjected to a temperature gradient. The temperature difference between the hot and cold junctions generates a voltage that is directly proportional to the temperature. This voltage can be measured and converted into a temperature reading using appropriate calibration techniques. Thermocouples offer advantages such as fast response time, high accuracy, and compatibility with different temperature ranges, making them versatile tools for temperature measurement.

What is a Thermometer?

Thermometer

Thermometer

A thermometer is an instrument specifically designed for temperature measurement. It uses various mechanisms, such as an expansion of liquids, gasses, or solids, to indicate temperature changes. Modern thermometers often incorporate advanced technologies, such as digital displays, remote sensing, or even temperature measurement without physical contact. For example, an infrared thermometer features a digital display and measures temperature without physical contact, making it safe and practical for various industrial applications.

The Hioki Infrared Thermometer FT3700/FT3701 is a non-contact thermometer that uses infrared rays to measure the surface temperature of objects accurately. It features a two-beam laser marker for precise measurements and is designed for industrial use.

Instantaneous Measurements and Continuous Measurements

The measurement methods can be categorized into instantaneous measurements and continuous measurements. Instantaneous measurements provide a snapshot of temperature or electricity at a particular instant, while continuous measurements capture values over an extended period. Understanding the distinctions between these two types of measurements is fundamental for selecting the appropriate methodology for different scenarios.

Examples of instruments for Instantaneous Measurements

Measurement Instruments for Electrical and Physical Parameters. Accurate measurement of electrical and physical parameters relies on specialized instruments tailored to each parameter. Here are the key electrical and physical parameters and their corresponding measurement devices.

Electrical Parameters

| Parameters | Instruments | Examples |

|---|---|---|

| Voltage | Digital Multimeters (DMM) are essential for voltage measurements. DMMs provide a versatile tool for measuring voltage, current, and resistance, among other electrical parameters. | |

| Current | Current measurements are made using Clamp Meters. These devices attach a clamp around a conductor, allowing for non-invasive current measurement. | |

| Resistance | Resistance Meters are designed for measuring resistance values accurately, aiding in circuit evaluation. | |

| Power | Power Meters are ideal for measuring power consumption and improving energy efficiency. |

Physical Parameters

| Parameters | Instruments | Examples |

|---|---|---|

| Temperature | Temperature measurement requires specialized tools such as Thermometers and Infrared Thermometers (Radiation Thermometers). They accurately measure the temperature of objects and environments, finding applications in various fields. | |

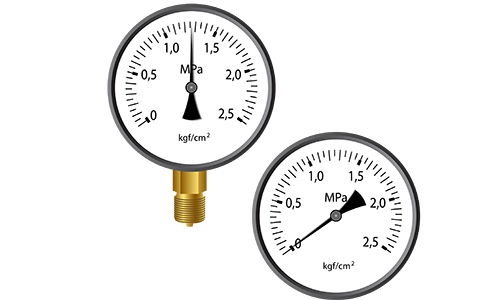

| Pressure | CPressure Gauges are employed for precise pressure measurements in gases and liquids, supporting process control and quality management. | |

| Force | Force Gauges measure the force applied to an object, serving purposes like material testing and product evaluation. |

These measurement instruments are critical for obtaining precise and reliable data in both electrical and physical parameter measurements. Selecting the appropriate instrument is essential for success across various industries and applications.

Data Loggers for Continuous Measurements

Data loggers are instrumental in continuously monitoring voltage, current, strain, and temperature over time. These devices can interface with various sensors, record and store data, and provide long-term data analysis. Electrical and physical monitoring, in particular, is crucial in many industries to ensure product quality, process optimization, and compliance with regulatory requirements. Data loggers are specifically designed for continuous measurements and offer features such as high storage capacity, long battery life, and compatibility with different temperature and other sensors. Some data loggers also come with advanced functions like recording and wireless connectivity. These data loggers are well-suited for applications that require detailed temperature recording and analysis.

These devices can be configured to record data from various sources, including electrical elements like voltage and physical parameters such as temperature, simultaneously at regular intervals. This enables the analysis of trends in electrical and physical data, the identification of fluctuations in these parameters, and the generation of reports. Data loggers are widely used in industries where precise control of electrical and physical conditions is essential, including electric vehicles, batteries, motors, electronic devices, and more.

Measurement Applications

Data loggers can be used to measure temperature for a variety of purposes. Here are some practical examples:

- Temperature monitoring in the battery manufacturing process

- In the battery manufacturing process, formation, a key step, allows stable energy storage. During formation, batteries undergo charging and discharging cycles, requiring cell voltage and temperature recording. This ensures battery health, equipment control, and traceability. The Data Logger LR8101, LR8102 in noisy environments, accurately recording data and minimizing costs. It's essential for quality battery production. Learn more about Data Logger LR8101, LR8102

- Environmental monitoring

- Collecting temperature data for the Earth's environment is essential for scientific research and forecasting, such as environmental protection and climate observation. Data loggers can be used to monitor outdoor and indoor temperatures and provide data on climate change.

- Temperature monitoring of electronic components in the development process

- Electric devices contain circuit boards with hundreds of electronic components. During the development process, engineers conduct temperature tests by monitoring the temperature of these components on the circuit board to ensure the safe operation of the devices. Data loggers can be used to monitor the temperatures of these electronic components during the development process to prevent overheating. This can improve the reliability of the end product.

As you can see, data loggers can be used to measure temperature for a variety of purposes. It is important to select the right data logger for your needs.

Things to Consider When Installing a Data Logger

Data loggers are essential tools for continuous monitoring of electrical and physical parameters, such as voltage, current, strain, and temperature. When installing a data logger, factors such as placement, calibration, and data storage duration must be considered to ensure reliable and accurate measurements over extended periods.

Data loggers are widely used in applications where continuous monitoring of temperature is required. When installing a data logger, careful consideration must be given to its placement to ensure representative temperature measurements. Factors such as proximity to heat sources, insulation, and airflow should be taken into account.

Additionally, regular calibration of the data logger is necessary to maintain measurement accuracy. The duration of data storage should also be considered, as it determines the amount of historical data that can be analyzed. By following these guidelines, engineers and scientists can ensure the integrity and reliability of temperature data collected by data loggers.

Hioki Products for Voltage, Current and Temperature Measurement