How Do You Measure a 0.1% Efficiency Improvement in ESS DC-DC Converters?

The Growing Energy Challenge in Data Centers – and the Role of ESSs

With the explosive growth of AI and cloud computing, data centers are consuming unprecedented amounts of electricity.

At hyperscale facilities, energy costs can exceed tens of millions of dollars annually.

To address both environmental and economic pressures, data centers are rapidly adopting renewable energy sources and implementing energy-saving strategies. One of the key solutions gaining traction is the Energy Storage System (ESS)—not just as a backup, but as a strategic infrastructure component that:

- Reduces peak demand charges by shaving power peaks

- Stabilizes renewable power fluctuations

- Provides ride-through support during sags and outages

- Decreases cooling load by improving PUE (Power Usage Effectiveness)

At the heart of every ESS lies the DC-DC converter. Its efficiency directly affects the overall system performance; inefficient conversion leads to wasted energy, increased heat generation, and ultimately, higher operating costs.

For Development Engineers: Accuracy Starts at 0.1%

The mission for DC-DC converter development is demanding but straightforward:

- "Deliver at least a 0.1% improvement in efficiency."

- "And prove it—quantitatively."

To meet these demands, development engineers must rely on precise measurements.

Yes, measuring large discharge currents during backup operation is a given—but the real challenge lies in distinguishing whether a 0.1% improvement is real or within the margin of error.

That’s where the power analyzer’s DC accuracy becomes critical.

For Production Line Managers: Match R&D Accuracy with Minimal Cost and Complexity

As production ramps up, DC-DC converters must be tested repeatedly across multiple lines. Test managers are tasked with balancing three key priorities:

- Ensure the same accuracy as R&D

- Build test systems that are as cost-effective as possible

- Avoid unnecessary equipment

"If we can do it with one instrument, we will."

That’s the on-the-ground reality in most factories.

Why ESS Requires Measurements Across a Wide Current Range

DC-DC converters in ESS applications operate in two distinct modes:

- Discharge mode:

Delivers several hundred amps to the grid or local load during peak hours - Charge mode:

Slowly recharges at 10 A or less, typically overnight, to protect battery health and reduce grid impact

This means the current spans from just a few amps to several hundred amps, depending on the mode. To evaluate performance in both cases, the measurement system must maintain high accuracy across a wide dynamic range. In other words, a power analyzer must deliver reliable results—not just at full load, but also during light-load charging conditions.

The Solution: Hioki Power Analyzer PW4001

Hioki’s PW4001 is purpose-built to meet the demanding requirements of DC-DC converter development and testing.

- ±0.04% rdg DC measurement accuracy

- Flexible current sensor options up to 1000 A

- Combines power and waveform analysis in one instrument

- Ready for automated inspection system integration

Visualizing Accuracy vs. Range: Why Sensor Selection Matters

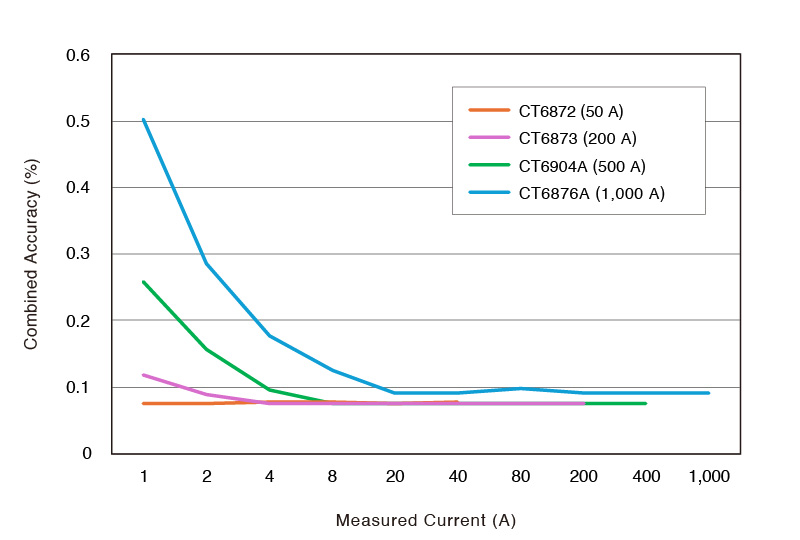

The PW4001 achieves ±0.04% rdg base accuracy—but real-world measurement also depends on the performance of the current sensor.

At low currents (e.g., during slow charging), the sensor's % of full scale (f.s.) error becomes dominant. At high currents, the % of reading (rdg) spec becomes more relevant.

Choosing sensors with low % f.s. error is key to maintaining accuracy at low loads.

Accuracy vs. Range Ratio

This graph clearly shows that to maintain 0.1% total error across both high and low current measurements, proper sensor selection and range setting are essential.

Use Case Examples

- R&D evaluation

PW4001 + CT6876A (1000 A sensor) : verify both waveform and power in a single system - Production testing

PW4001 + compact clamp sensor : maintain accuracy while minimizing equipment count - Line expansion

PW4001 × N units across all lines : consistent accuracy with standardized test recipes

Conclusion: High-Accuracy Testing Without Compromising Cost

Hioki's PW4001 gives you:

- ±0.04% rdg DC accuracy to support confident efficiency validation

- Combined power and waveform analysis in a single device

- A scalable platform for both development and high-throughput testing

"Match R&D accuracy on the production floor—with fewer instruments and lower cost." That’s what the PW4001 makes possible.

For detailed product information, please visit our website.

For a demonstration or consultation on a specific application, please contact us.