Lithium-ion Battery Production and Testing

Learn how Hioki can help your Li-ion battery inspection/testing in each production process

Li-ion Battery Production Process

Mixing

Active materials, conductive auxiliary agents, polymer binders, and organic solvents are mixed together to form an electrode slurry.

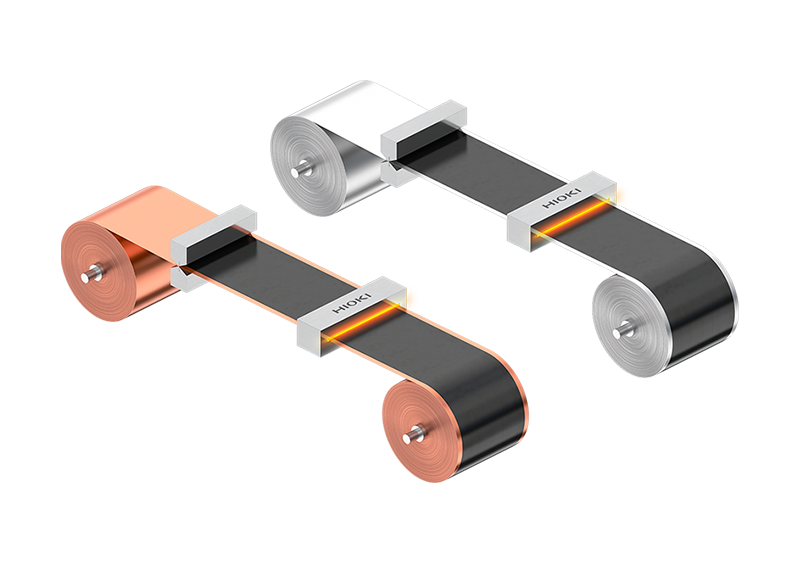

Coating, Drying, and Calendering

The electrode slurry is coated to copper and aluminum foil, dried, and calendared.

Slitting

The electrode sheets are slit to each battery size.

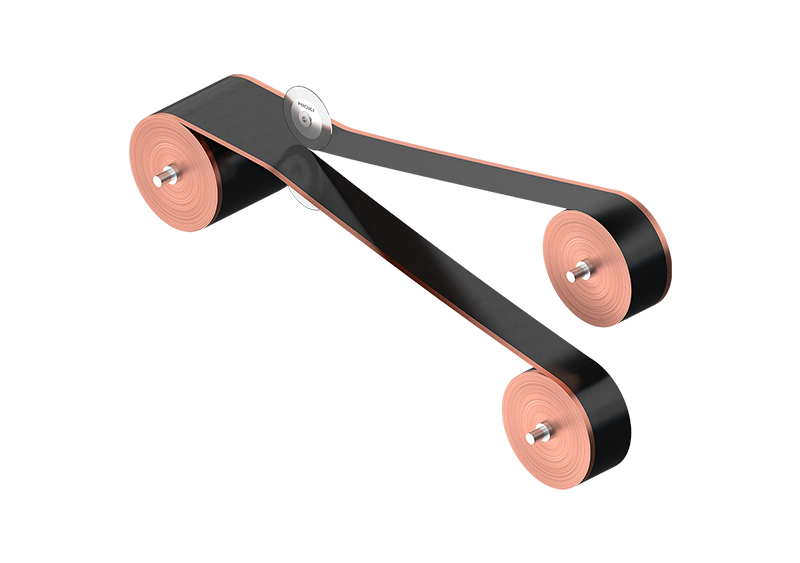

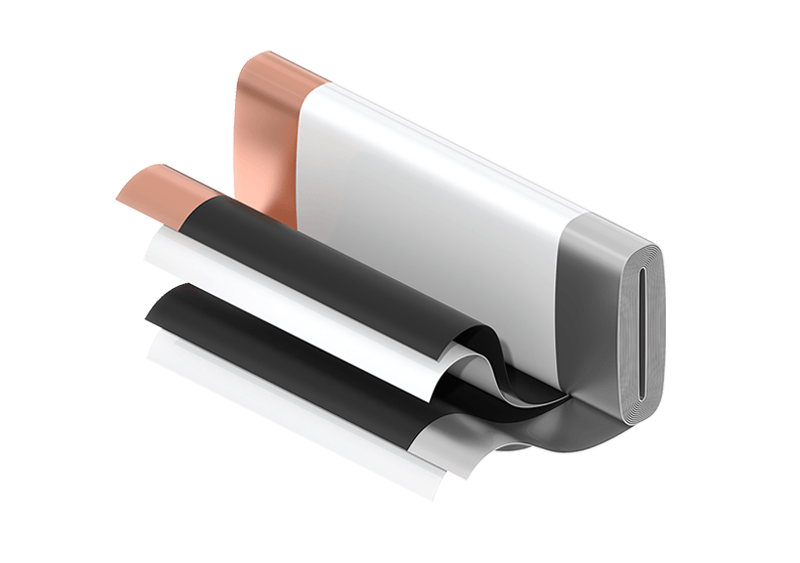

Winding or Stacking

A separator is inserted between the anode and cathode electrode sheets, and the electrode sheets are wound or stacked together.

Tab Welding

The tabs of the layered electrode sheets are welded together, and collectors are welded to the tabs.

Terminal Welding

The covers and collectors are welded together.

Assembly

Case Closing

The covers and cases are welded together.

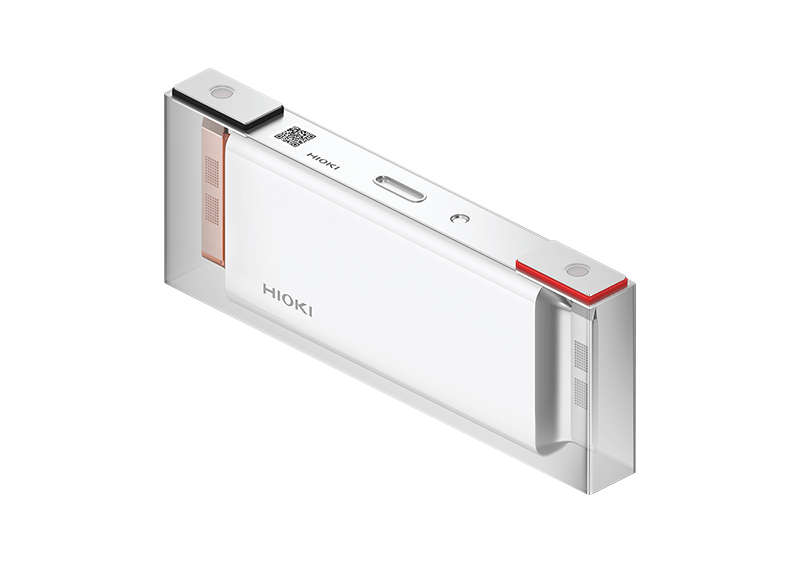

Before Filling

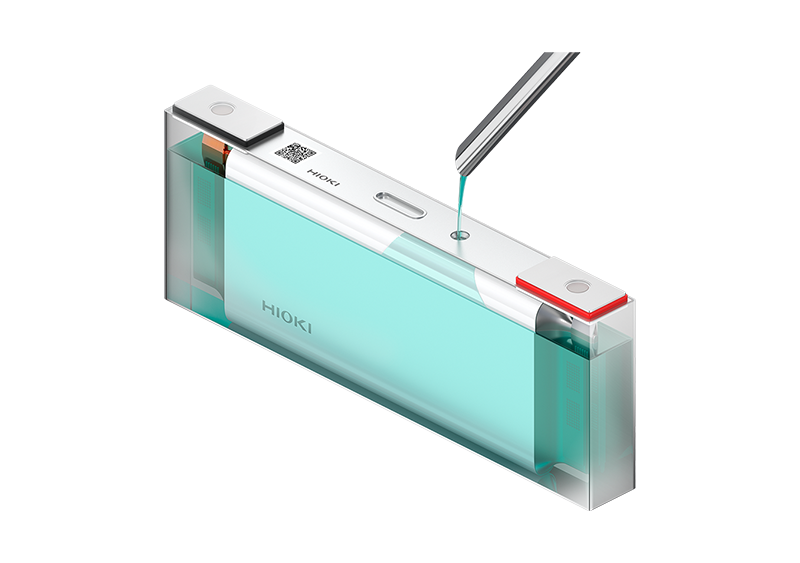

Electroyte Filling

Electrolyte is filled via the electrolyte port.

After Filling

The electrolyte port is closed.

Pre-charging

Following electrolyte fill, a charging current is fed to the cells for the first time.

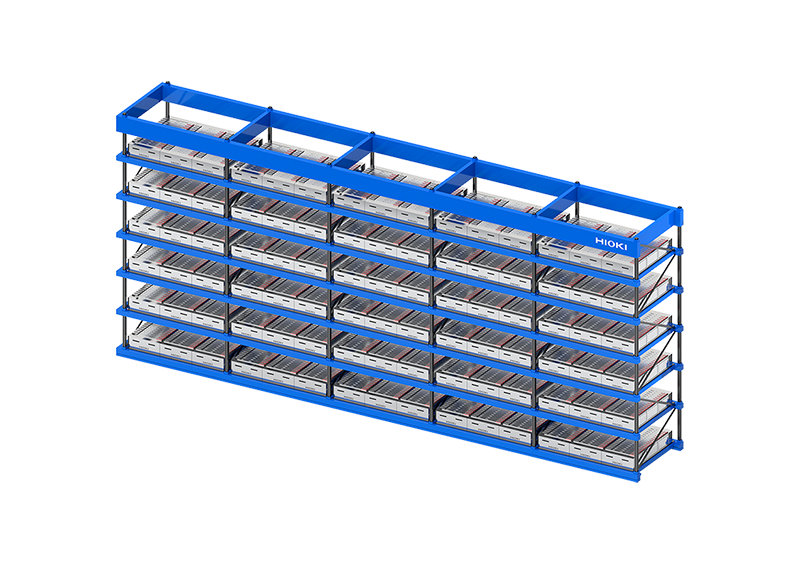

Charging and Discharging

The cells are repeatedly charged and discharged.

Aging

The cells are stored for a certain period of time.

Pre-shipment inspection

Quality is tested prior to shipment.

Li-ion Battery Inspection and Testing Methods

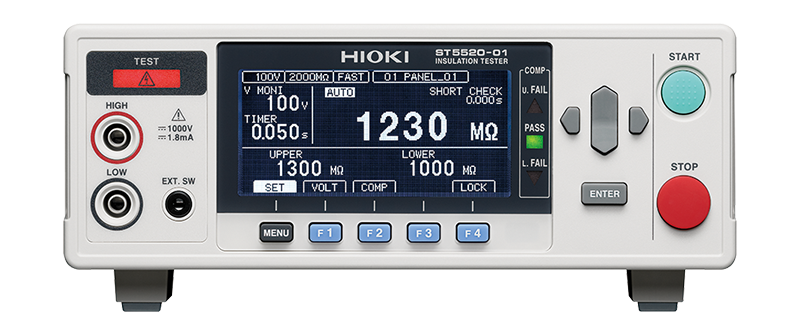

Lithium-ion Battery Insulation Resistance Testing

Structurally, it’ s necessary to keep the anode and cathode electrodes, as well as the electrodes and enclosure (case), insulated from each other. Failure to keep those components properly insulated—in other words, insufficient insulation resistance - could lead to a risk of ignition or fire accidents.

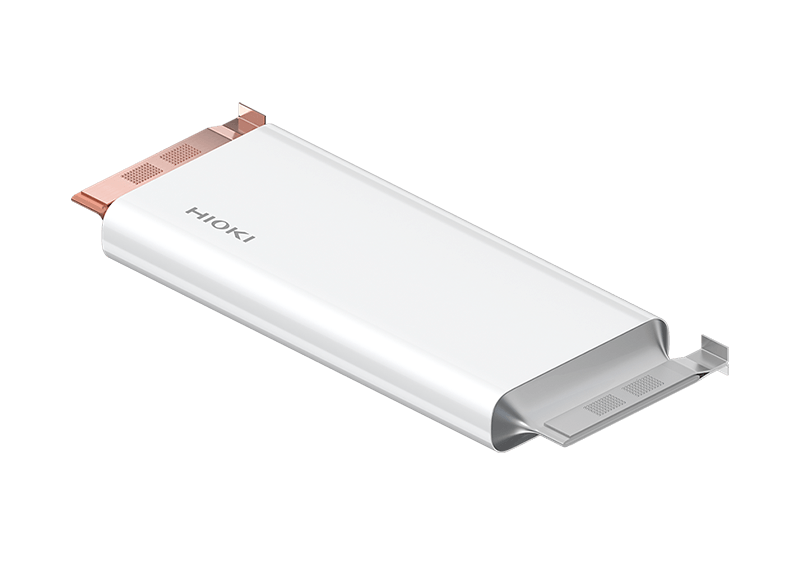

- BATTERY INSULATION TESTER BT5525

- INSULATION TESTER ST5520

- SUPER MEGOHM METER SM7110

- SUPER MEGOHM METER SM7120

This type of testing measures the insulation resistance between battery cells’ anode and cathode electrodes, and between the electrodes and the enclosure.

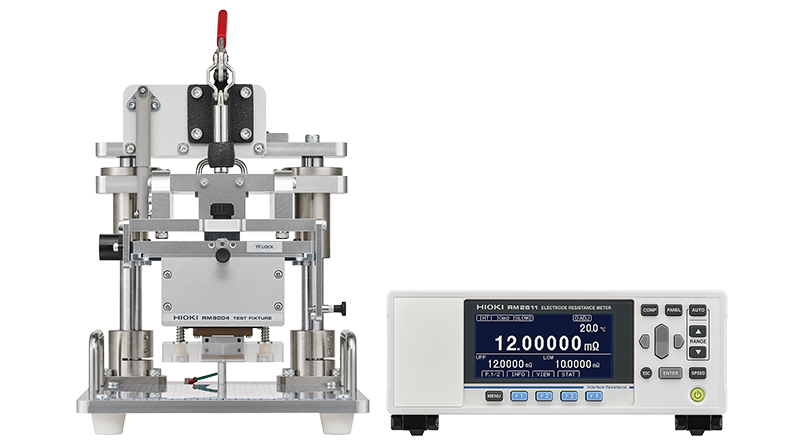

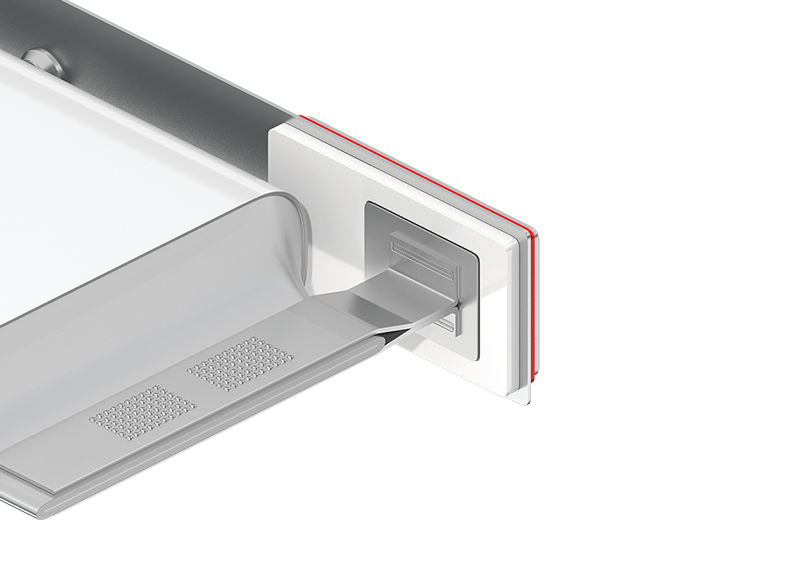

Lithium-ion Battery Weld Quality Testing

If welds connecting tabs, collectors, and other battery components are insufficient, resistance between components will increase significantly, resulting in electrical energy loss and battery overheating. Such heating can reduce the battery’ s service life or cause fire.

This type of testing measures the resistance between welded components.

Charge/Discharge Testing of High-Voltage Batteries

Voltage and temperature are recorded during the charging and discharging test process in order to monitor changes in battery state. Recorded data is then analyzed to detect defects and rank batteries.

This type of testing records fluctuations in battery cells’ voltage and temperature across multiple channels.

Lithium-ion Battery Internal Resistance Testing

Although batteries’ internal resistance would ideally be zero, internal resistance exists due to a variety of factors. Internal resistance increases as a battery degrades.

This type of testing measures battery cells’ internal resistance.

Lithium-ion Battery Open-circuit Voltage (OCV) Testing

A battery’ s voltage when it is not connected to any load is known as the open-circuit voltage (OCV). OCV values gradually decline due to self-discharge, a characteristic of batteries. When a battery has an internal defect, self-discharge increases, causing the OCV to decrease beyond the defined value.

- PRECISION DC VOLTMETER DM7276

- BATTERY IMPEDANCE METER BT4560

- BATTERY HiTESTER BT3561A

- BATTERY HiTESTER BT3562A

This type of testing measures battery cells’ open-circuit voltage.

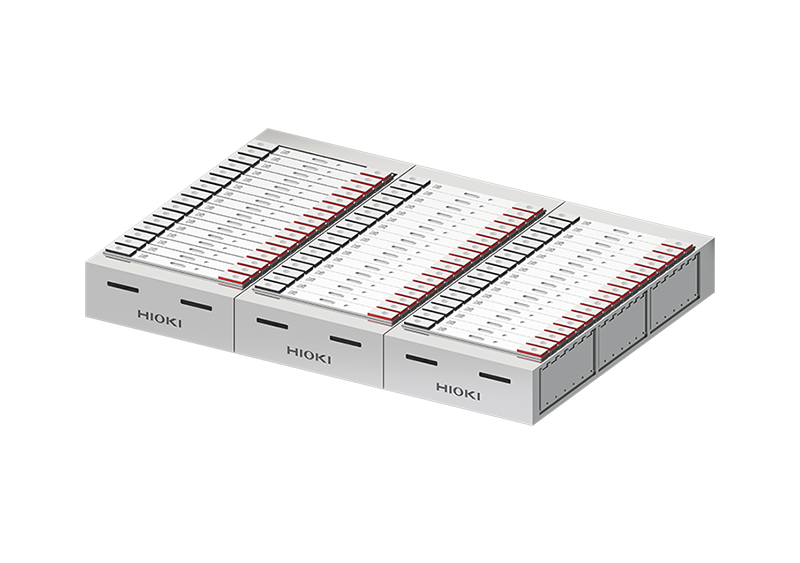

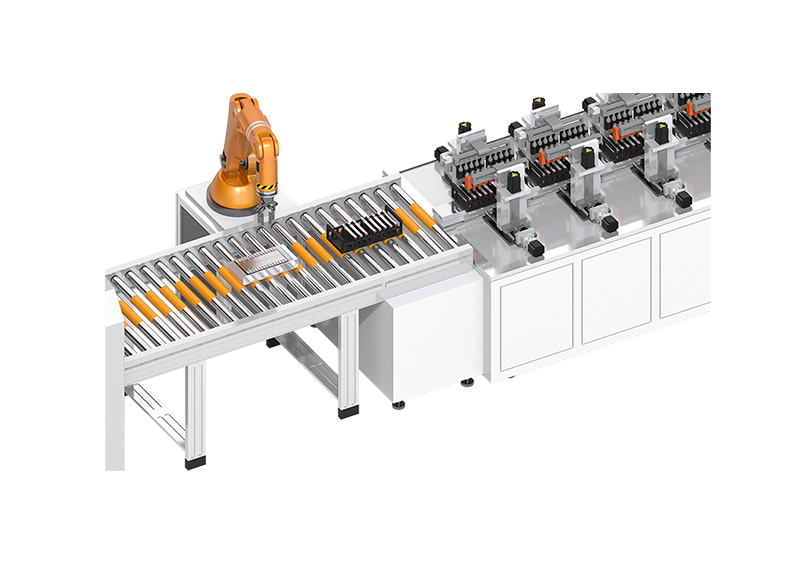

Reducing testing times with multichannel measurement

Testing times can be reduced by increasing the number of measurement channels, helping shorten lead times.

The DM7276, BT3562A, and BT4560 support up to 264, 132, and 72 channels, respectively. In addition, the SW1002 can connect to two different instruments, and the switching between them can be done automatically.

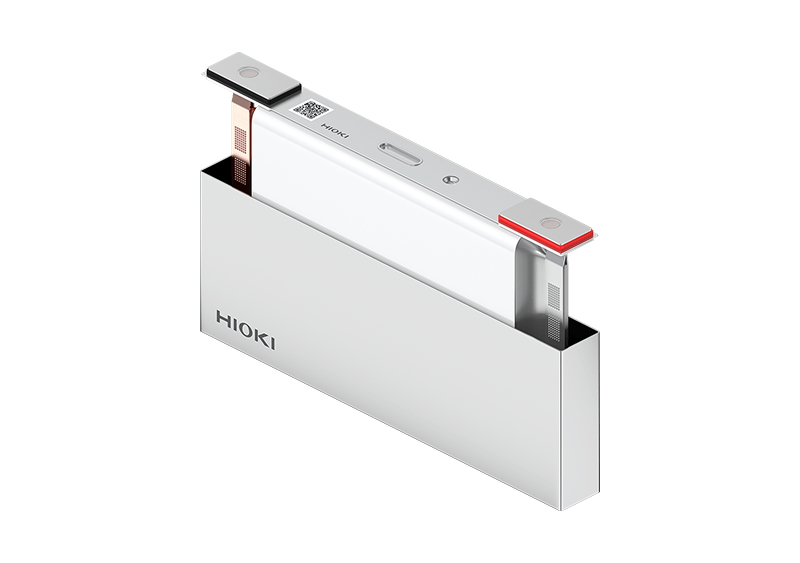

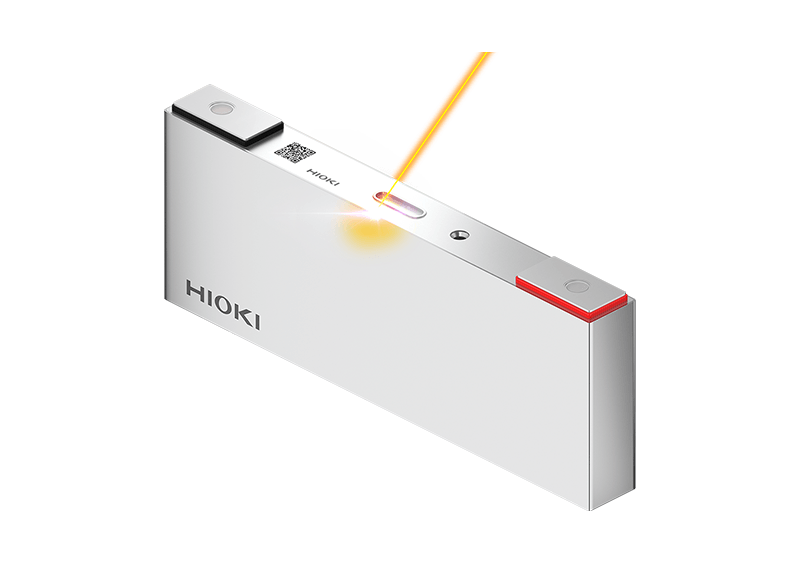

Managing electrode sheet manufacturing quality

To produce electrode sheets with favorable characteristics, manufacturers study materials, composition, and manufacturing conditions based on two indicators: the composite layer resistance and the interface resistance between the composite layer and collector.

The system allows users to visualize those two quantities by measuring the surface of the electrode sheet with a test fixture that consists of an array of test probes and then using proprietary analytical.