Product Jan. 08, 2025

Hioki Upgrades Resistance Meter to RM3548-50 with User-Friendly Design and Instant Connectivity

Resistance Meter RM3548

Nagano, Japan, 8th January 2025 – Hioki E.E Corporation proudly announces the upcoming release of the RM3548-50 Resistance Meter on January 8, 2025, designed specially for the growing electric vehicle (EV) maintenance market. As the successor to the highly regarded model RM3548, the RM3548-50 comes equipped with advanced features such as protective casing, Bluetooth® connectivity, and specialized probes (sold separately) for EV maintenance.

Resistance measurement plays a critical role in EV maintenance by ensuring the integrity of electrical and mechanical connections in key components, such as screw fastenings and welded joints. The new RM3548-50 is engineered to streamline this essential task, offering improved efficiency and reliability for maintenance professionals.

With its enhanced capabilities, the RM3548-50 is poised to contribute to the rapid advancement of the EV industry, supporting the increasing demand for high-quality, efficient maintenance solutions.

Development Background

As the world works toward carbon neutrality, the electric vehicle (EV) market continues its rapid growth, with global sales projected to reach around 17 million units in 2024.1 This expansion is driving a parallel rise in demand for EV maintenance. Proper maintenance is essential for ensuring the safety and optimal performance of EVs, extending their lifespan, and increasing their reuse value.

In the field of EV maintenance, technicians face the challenge of handling high-voltage systems while maintaining safety and improving efficiency. To address these needs, Hioki introduced the EV Maintenance Toolkit in January 2024. This comprehensive EV Maintenance Toolkit includes a resistance meter, infrared thermometer, digital multimeter, an insulation resistance meter, and a work flow manual – essential tools for ensuring the proper connection and EV components. The newly released RM3548-50 Resistance Meter is an upgraded successor to the resistance meter in the original toolkit, the RM3548. This resistance meter plays a crucial role in measuring the resistance of screws and welds to verify the secure connection of critical components, such as EV chassis and shielding.

With enhanced features and additional options, the RM3548-50 further improves safety and efficiency in EV maintenance. Its new functions elevate the overall performance of the toolkit, making it an indispensable tool for professionals working with EVs.

Beyond EVs, resistance meters like RM3548-50 are also used in similar applications for aircraft chassis maintenance, where the demand for more efficient measurement probes has been growing. In response, Hioki has added new measurements probes tailored for aircraft maintenance, further expanding the versatility of the RM3548-50.

Through the continuous development and refinement of products like the RM3548-50, Hioki is committed to supporting the widespread adoption of EVs and contributing to the realization of a sustainable future.

New RM3548-50 Improved with Protective Casing and Backlit Display

New Improvements

Protective Casing and Backlit Display for Safe, Reliable measurements in Tough Environments

EV maintenance often requires work in tight, dimly lit spaces, such as under the vehicle body. The RM3548-50 is designed to handle these tough conditions with ease. It features a protective casing that safeguards both the measuring instrument and the vehicle from potential impacts in confined areas. Additionally, the instrument's backlit display ensures that measurement values can be easily and clearly read, even in dark environments, providing technicians with both safety and reliability during critical tasks.

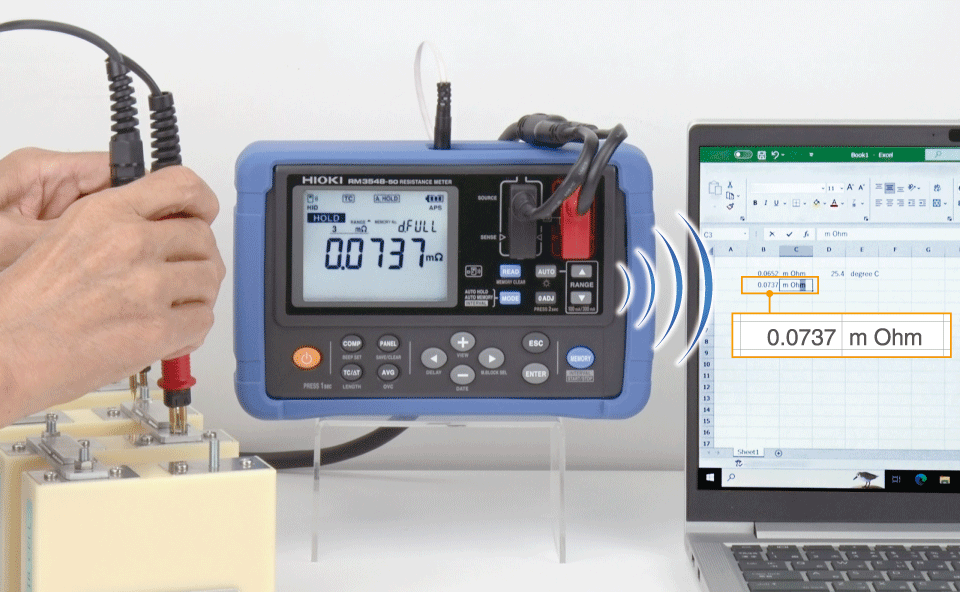

Enhanced Efficiency Through Digitalization

Traditionally, EV maintenance technicians had to manually record data or transfer it to a PC, adding time and effort to the process. The RM3548-50 addresses this by offering a communication function through the optional Z3210 Bluetooth® communication module (sold separately). This feature allows seamless data transfer and integrates with Hioki’s GENNECT Cross application2, enabling digital data recording and report generation. By digitizing the workflow, the RM3548-50 significantly improves the efficiency of data management and report creation, streamlining the overall maintenance process.

- 1: GENNECT Cross: A free app for iOS and Android provided by Hioki. It connects measuring instruments to smartphones and tablets via Bluetooth® communication, and enables recording of measurement values and creation of reports.

Versatile Optional Probes for Specialized Applications (sold separately)

In resistance measurement, the way the measurement terminals make contact with the target is just as crucial as the performance of the instrument itself. To complement the RM3548-50, Hioki has expanded its lineup with new optional probes designed to enhance inspection efficiency in both EV and aircraft maintenance.

- Test Lead L2140: A probe designed for EV maintenance with an extended 3-meter cable, ideal for large vehicles where components are positioned far apart, such as positive and negative terminals located at a distance, such as on the vehicle’s underside.

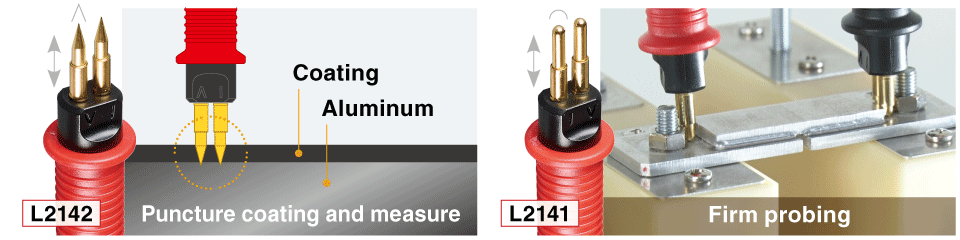

- Pin-type Lead L2141: Developed for aircraft shipment inspections, this probe features a rounded pin terminal. It allows for precise resistance measurements without damaging the surface of sheet metal, particularly important before the painting process.

- Pin-type Lead L2142: Designed for aircraft maintenance, this probe features a robust spring and needle-type pin terminal capable of penetrating paint coatings on metal surfaces. While traditional probes often sustain wear from repeated measurements, the L2142’s durable spring and pin terminal withstand the pressure required to penetrate paint, allowing accurate readings without damaging the material. Engineers can then simply touch up paint on the measurement points as needed, preserving the integrity of the surrounding surface.

Main applications

- Measuring the connection resistance of chassis in EV maintenance and aircraft maintenance

- Measuring the connection resistance of bus bars in electrical equipment and batteries

- Measuring the winding resistance of motors and transformers

- Measuring the resistance of cable drums (measuring the length of cables by converting resistance values)

Link

For more information, please refer to RM3548-50 Product website.

Contact us

For inquiries such as quotes, demonstrations, and trial usage, please use Hioki’s contact form for a personalized reply from your closest or most appropriate Hioki representative.

- The information provided is current as of the date of publishing.

- Please note that prices, specifications, and other information contained in this texts are subject to change without notice.

- The company names and product names used in this text are registered trademarks or trademarks of their respective companies.

About HIOKI

Established in 1935, HIOKI E.E. CORPORATION (TSE: 6866) has grown to become a world leader in providing consistent delivery of test and measuring instruments through advanced design, manufacturing, and sales and services. By offering over 200 main products characterized by safety and quality while meeting an expansive range of applications, we aim to contribute to the efficiency and value of our customers' work in research and development, production and electrical maintenance. Hioki products and services are available around the world through our extensive network of subsidiaries and distributors. For more information, visit us at www.hioki.com.