Lithium-ion Battery Internal Resistance Testing

What is internal resistance testing of lithium-ion batteries?

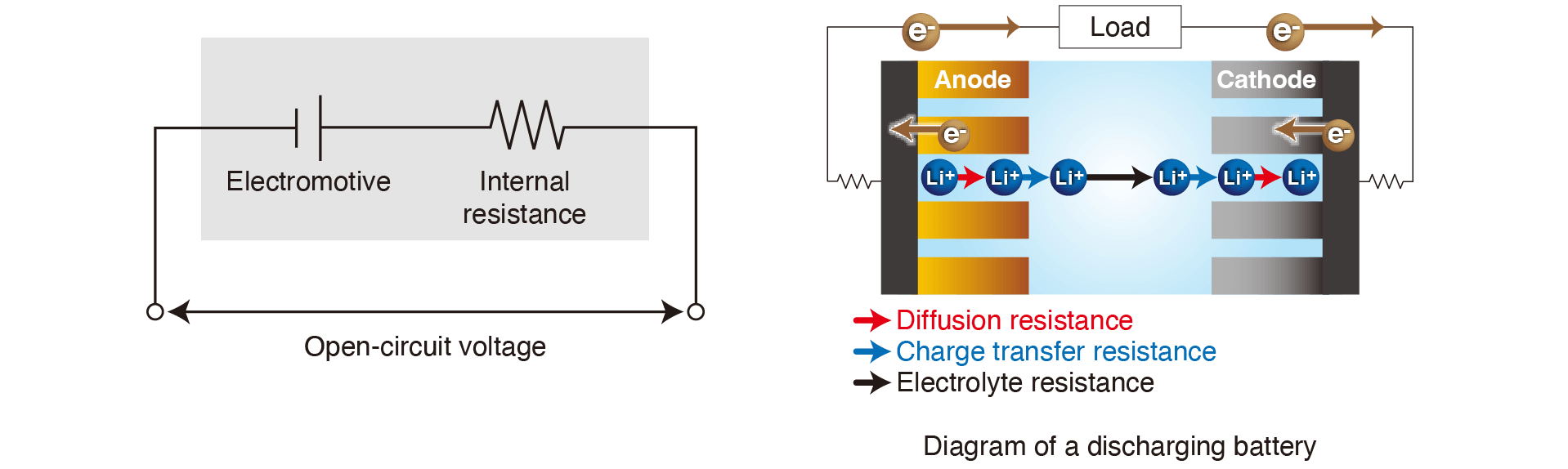

Although batteries’ internal resistance would ideally be zero, internal resistance exists due to a variety of factors. Internal resistance increases as a battery degrades. On battery cell production lines, defective cells are detected by comparing the internal resistance of tested cells to that of known-good reference cells.

When to test internal resistance

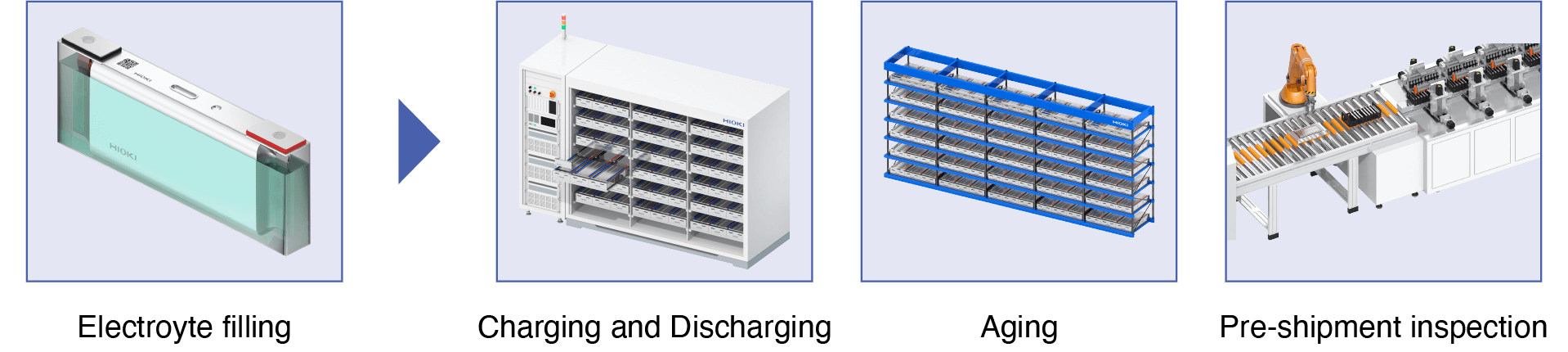

Internal resistance testing is carried out at each process after battery cells are filled with electrolyte and their assembly completed (charge/discharge testing, aging testing, shipping inspections, etc.).

How to measure internal resistance

There are two methods for measuring internal resistance: the AC method (AC-IR) and the DC method (DC-IR). Testing on production lines uses the AC method, which is introduced by this article.

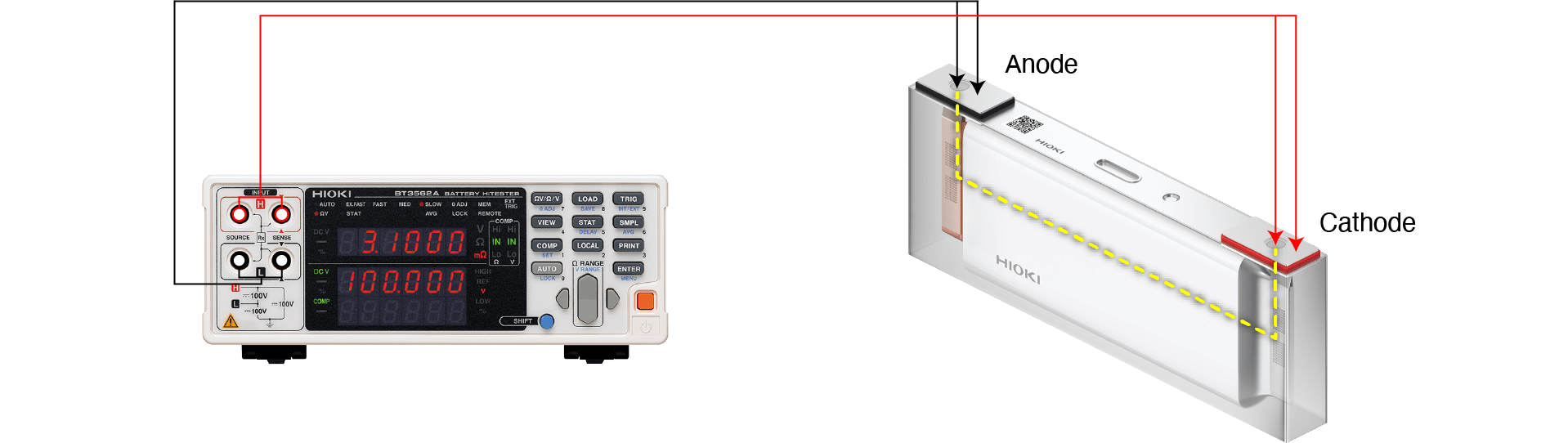

When measuring the internal resistance of a battery cell using the AC method, an AC resistance meter specifically designed to measure low resistance levels (i.e., a battery tester) is used. AC resistance meters apply a constant-current AC signal to the battery. They then detect the minuscule voltage generated by the current and calculate the resistance value.

Note that DC resistance meters cannot measure batteries, which have non-zero voltage or electromotive force.

(Learn more: Differences of Resistance Measurement Methods)

- AC method (AC-IR) and DC method (DC-IR):

Measurement method varies depending on the equipment configuration.

- AC resistance meters and DC resistance meters:

Measurement method varies depending on whether an AC or DC measurement signal is applied to the battery.

- 4-terminal method (Four-terminal measurement)

- Measurement range and resolution

- Noise resistance

- Measurement frequency

- *1:Available to convert the 4-terminal pair measurement to 4-terminal measurement with the conversion plug.

- *2:Battery testers can simultaneously measure both internal resistance and open circuit voltage (OCV).

Key considerations when choosing an AC resistance meter (battery tester)

When your goal is to test battery cells’ internal resistance, it’s important to be able to measure low resistance levels accurately. (The larger a battery cell, the lower its internal resistance. Battery cells used in vehicles typically have an internal resistance less than 1 mΩ.)

The following considerations should be taken into account when choosing an AC resistance meter (battery tester):

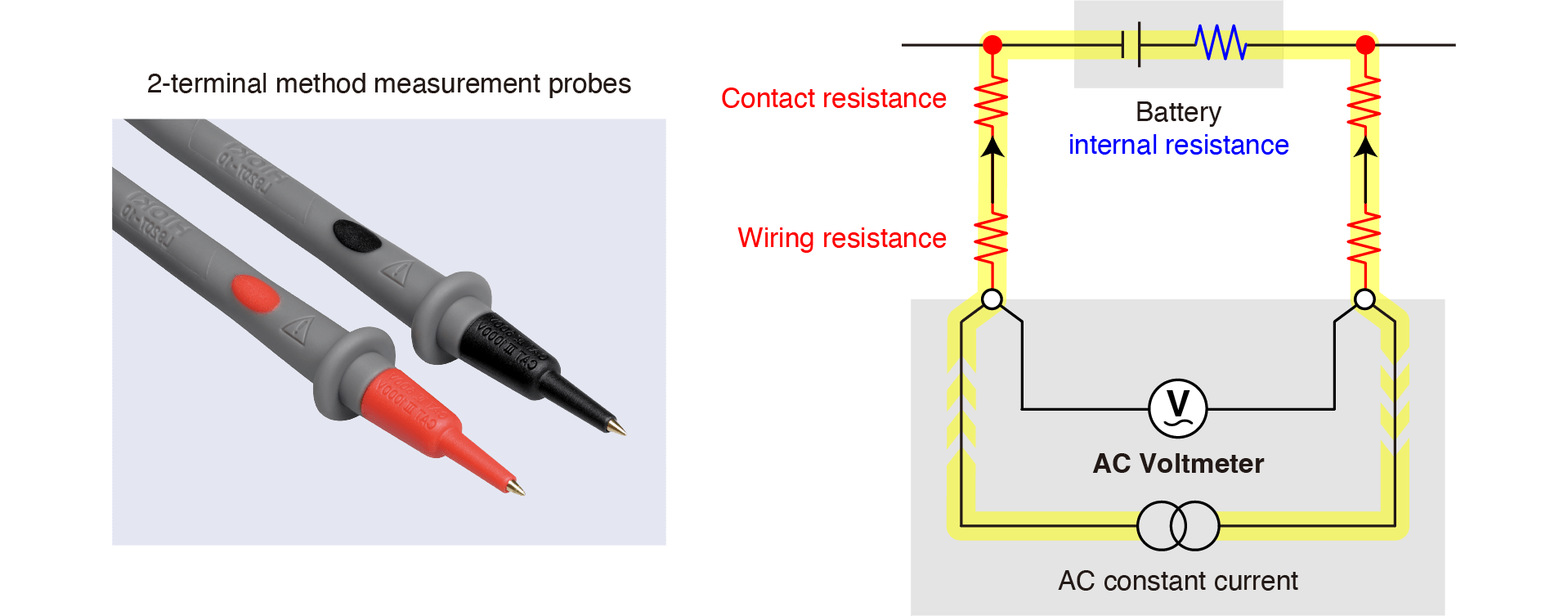

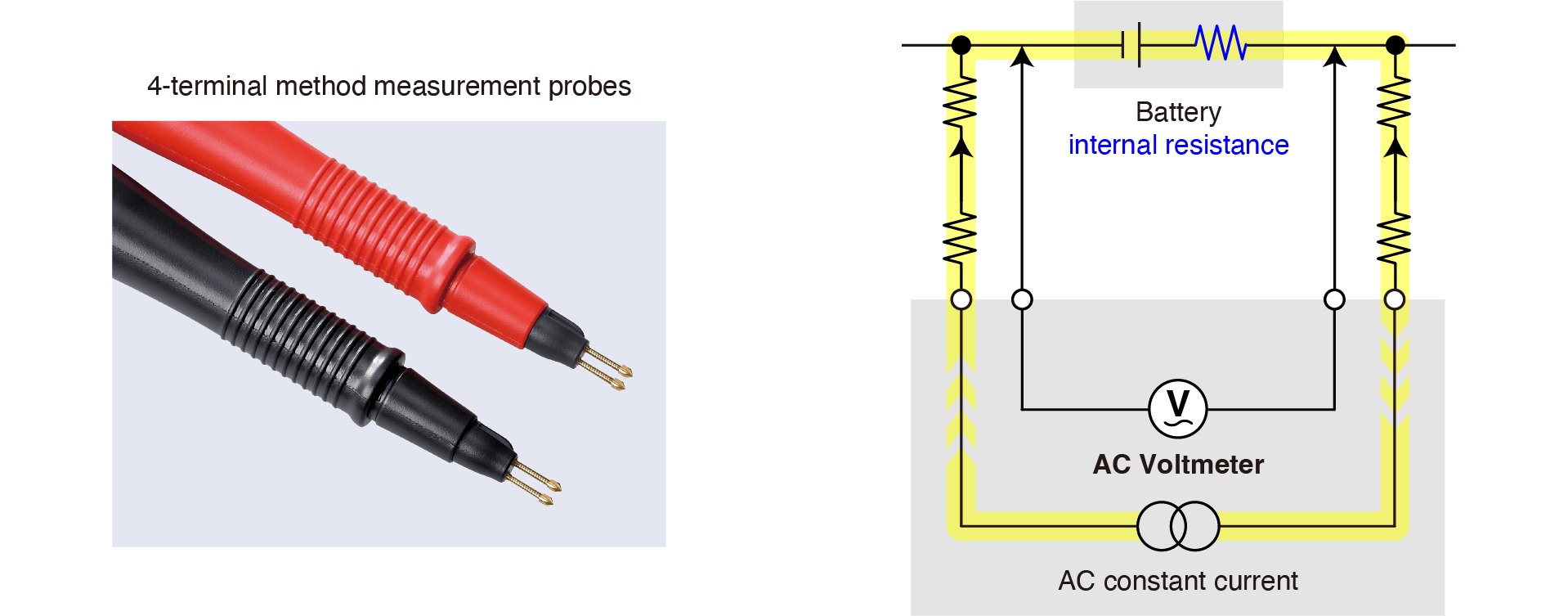

4-terminal method (Four-terminal measurement)

When measuring low resistance levels of 1 Ω or less, internal resistance is measured using the 4-terminal method. Resistance can be measured using either the 4-terminal method or the 2-terminal method. Since measured values obtained using the 2-terminal method include path resistance (i.e. wiring resistance and contact resistance), low resistance cannot be measured accurately.

(Learn more: 4-terminal resistance measurement method)

Detected voltage = Applied current × (Internal resistance + Contact resistance + Wiring resistance)

The resistance value is calculated from the detected voltage. The value can include excess resistance components.

Detected voltage = Applied current × Internal resistance

The resistance value is calculated from the detected voltage. It does not include any excess resistance components.

Measurement range and resolution

To measure low resistance levels of 1 Ω or less, an instrument needs to provide a milliohm-order measurement range as well as microohm-order resolution. Low resistance levels on the order of milliohms can not be measured accurately if the range and resolution is not enough.

Noise resistance

Even if an instrument’s specifications provide a good measurement range, resolution, and measurement accuracy, it may not be possible to accurately measure resistance values. In some cases, the surrounding electric noise may make measured values unstable and prevent the instrument from presenting precise readings. (There are various sources of noise, including power supplies or production equipment.)

During the development of measuring instruments, noise resistance tests are generally performed to verify their performance in noisy environments. Products not subjected to such testing may not fulfill their measurement specifications when used on production lines.

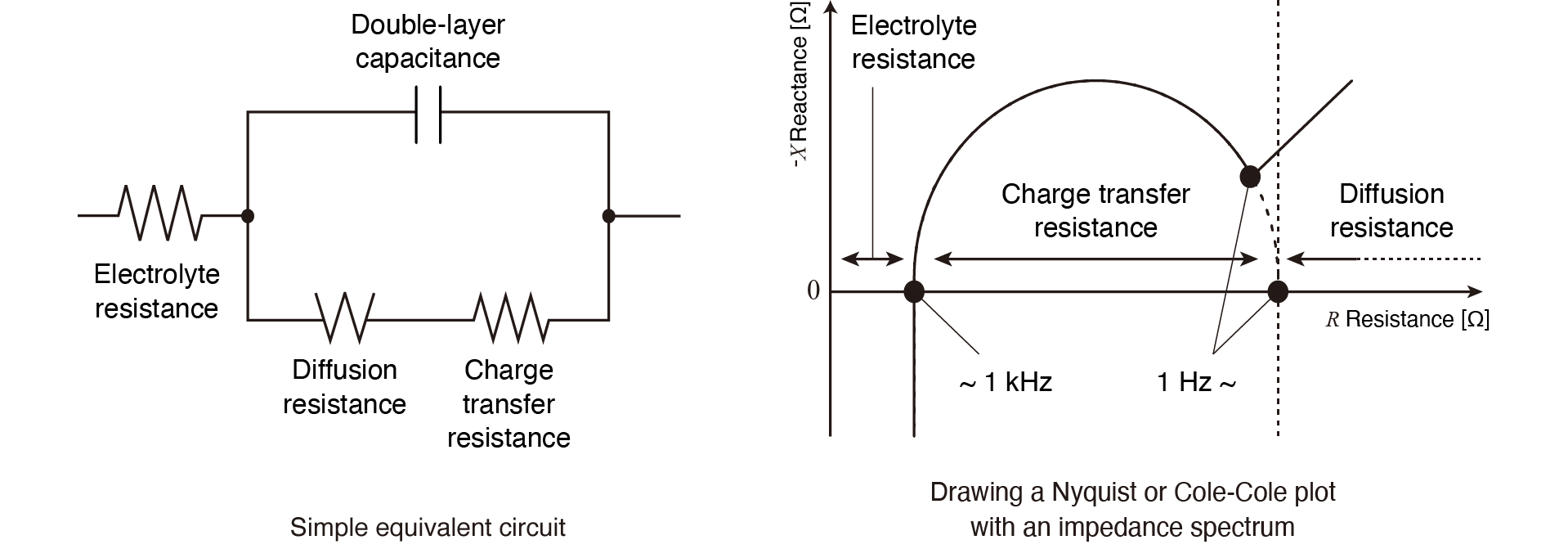

Measurement frequency

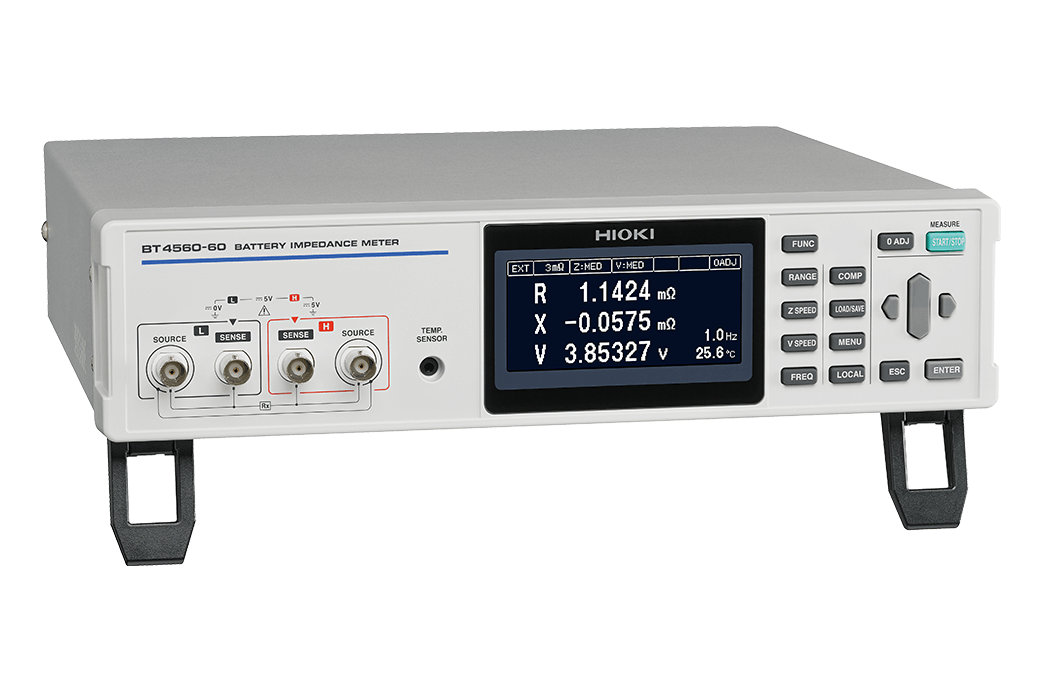

AC resistance meters (battery testers) apply a constant-current AC signal to the battery. This AC signal generally has a fixed frequency of 1 kHz, although some products allow the frequency to be varied. With a Nyquist plot drawn from the impedance values measured while sweeping through a range of frequencies, it’s possible to segregate the battery’s internal resistance into components such as diffusion resistance, charge transfer resistance resistance, and electrolyte resistance. Recently, more and more manufacturers are opting to perform internal resistance testing at multiple frequencies so that they can detect defective cells more effectively.

Battery testers from Hioki

Hioki’s battery testers are working at battery manufacturers around the world. The following models are used in internal resistance testing in battery cell production processes.

| Product model | BT3561A | BT3562A | BT4560-50 | BT4560-60 |

|---|---|---|---|---|

| Measurement method | AC 4-terminal method | AC 4-terminal method | AC 4-terminal pair method (*1) | AC 4-terminal pair method (*1) |

| Measuring range/resolution | —/— | 3.1000 mΩ/ 0.1 μΩ | 3.6000 mΩ/ 0.1 μΩ | 3.6000 mΩ/ 0.1 μΩ |

| 31.000 mΩ/ 1 μΩ | 31.000 mΩ/ 1 μΩ | 12.0000 mΩ/ 0.1 μΩ | 12.0000 mΩ/ 0.1 μΩ | |

| 310.00 mΩ/ 10 μΩ | 310.00 mΩ/ 10 μΩ | 120.000 mΩ/ 1 μΩ | 120.000 mΩ/ 1 μΩ | |

| 3.1000 Ω/ 100 μΩ | 3.1000 Ω/ 100 μΩ | —/— | —/— | |

| 31.000 Ω/ 1 mΩ | 31.000 Ω/ 1 mΩ | —/— | —/— | |

| 310.00 Ω/ 10 mΩ | 310.00 Ω/ 10 mΩ | —/— | —/— | |

| 3.1000 kΩ/ 100 mΩ | 3.1000 kΩ/ 100 mΩ | —/— | —/— | |

| CE | ✔ | ✔ | ✔ | ✔ |

| CSA | ✔ | ✔ | ✔ | Certification in progress |

| Measurement frequency | 1 kHz ±0.2 Hz | 1 kHz ±0.2 Hz | 0.01 Hz to 1050 Hz | 0.01 Hz to 10.00 kHz |

| Open circuit voltage (OCV) measurement (*2) | ✔ | ✔ | ✔ | ✔ |