A Guide for Safe Electrical Testing of Electric Vehicle (EV) Maintenance and Service

A BEV (battery electric vehicle) is an electric vehicle (EV) that runs solely on battery power and is charged from an external source. The voltage that BEVs run on have grown increasingly in recent years. However, this high voltage comes with a price; it necessitates several precautions when performing maintenance and inspections. In this article, we will discuss the various electrical tests that are required for technicians, from disconnecting the high-voltage (HV) battery to initializing an EV.

Note: For more information on how to disconnect and initialize an electric vehicle, please check with the vehicle manufacturer.

Shutting down the HV system of the vehicle

Before proceeding to electrical testing and measurement, make sure to shut down (*1) the vehicle's HV system by disconnecting the service plug or switch. For safety, be sure to carry out a visual inspection and look out for engine faults by performing a DTC (Digital Trouble Codes) scan.

- *1:The removal of high-voltage components is hazardous work. Ensure that qualified personnel specified by the laws and regulations with professional training perform the work. For details, please follow the operation manual of each vehicle manufacturer.

Temperature measurement of the HV batteries

Measure the surface temperature of the HV battery with a non-contact thermometer. In this inspection, check for variations in temperature as well as areas of high temperature.

- Instrument used: INFRARED THERMOMETER FT3701

- The FT3701 is an infrared thermometer with a two-point laser marker that measures the average surface temperature inside a circle formed by the two points.

Disconnect the HV battery cable and allow it to discharge

After performing a zero-voltage measurement (see below), disconnect the high-voltage (HV) cable and wait at least 10 minutes for the HV system to discharge. To avoid a serious accident, it is necessary to wait for a certain period of time.

Take note that the discharge time may vary, so make sure to check with the vehicle manufacturer.

For reference, the locations of the measurements are labeled as follows:

- A: Inverter, motor etc

- B: Chassis

- C: HV cable

- D: HV Batteries

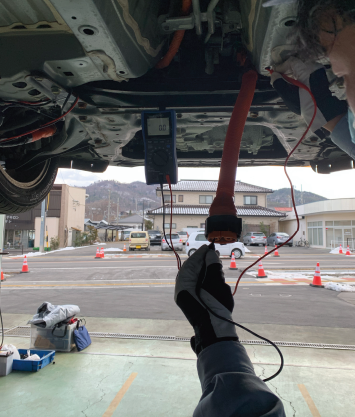

Zero-voltage measurement

This measurement is conducted to prevent electric shock and to make sure that the vehicle is shut down. Measure the voltage on surfaces that are likely to be touched when unplugging the HV connector. Also, after unplugging the HV battery’s connector, make sure that the HV system is shut down. In this test, voltage should be measured between the specifc points and chassis ground of the vehicle. It should show up as zero volts (0 V).

This test is performed three times:

- 1. Before disconnecting the HV cable between the HV battery and the inverter.

- 2.After disconnecting the HV cable between the HV battery and the inverter.

- 3. Before reconnecting the HV cable between the HV battery and the inverter.

- Instrument used: DIGITAL MULTIMETER DT4261

- The DT4261’s terminal shutters make it physically impossible to insert the wrong test lead when measuring. Without this function characteristic to Hioki DMMs, an honest mistake in connection can cause extreme injury by voltage overload to the DMM.

- The LoZ (low input impedance) mode gets rid of the effects of ghost voltages caused by the measurement target's stray capacitance and the multimeter's high input impedance. This lets you get accurate readings.

After the above test, the HV system shut-down is officially over. Now that the safety of the vehicle is ensured, the repair and inspection work on electric vehicles can be carried out.

Repair, inspection and replacement of HV components

Equipotential bonding test

This test is conducted when high-voltage (HV) components have been installed or replaced. Electrically check that all chassis, shields, and other components are connected without any problem. Measure the resistance of the ground connection at the area where the chassis of the vehicle and the HV components are connected. If the resistance value is high or the resistance value differs significantly from the measured value, the connection of the HV component may have been installed incorrectly.

- Instrument used: RESISTANCE METER RM3548-50

- RM3548-50 is a four-terminal (four-wire Kelvin) DC milliohm meter.

- The test current ranges is from 500 nA to 1 A. This meets the ECE-R100 (*2) standard's requirement for excellent measurement precision.

- *2:Safety standard for electric powertrains of road vehicles including rechargeable battery systems.

Insulation resistance test

In this test, we verify that there are no flaws in the insulation between the HV system and the ground. The insulation test is performed on both the connector of the HV battery (battery side) and the connector of the inverter (inverter side). The test is carried out between each of the sides (battery and inverter) and the chassis ground of the vehicle. This measurement requires a test voltage greater than the vehicle’s battery voltage. Please keep in mind that the test voltage may vary based on the vehicle model.

- Instrument used: INSULATION TESTER IR4059

- For the HV range (500 V or 1000 V), the IR4059 has a safety feature that requires the technician to unlock in addition to choosing the voltage to prevent unintentional HV accidents.

- The test lead with remote switch, L9788-10 (included accessory), is equipped with an LED, which helps with visibility and instantaneous pass/fail judgments while the measurement is in progress.

Zero-voltage measurement

When the repair or inspection is finished, take a zero-voltage measurement on the inverter side and the battery side before safely reconnecting the HV system.

Reconnecting the HV system of the vehicle (re-initialization)

Install the high-voltage cable, service plug (aka switch) , and return the vehicle's HV system to energized status.

Lastly

As the world moves toward decarbonization, electric vehicles are becoming more common in our daily lives. To ensure the safety of both technicians and electric vehicles (EVs), electrical testing is essential. At Hioki, we provide safety solutions and tools for both technicians and electric vehicles. Check out our reading recommendations for more knowledge on electrical measurement for electric vehicle maintenance.