AC/DC CURRENT PROBE CT6844-05

500 A AC/DC Wideband and High-Precision Current Probe for Power Efficiency Testing

Discontinued

-

-

-

Insulated conductor

Insulated conductor -

Hioki AC/DC clamp sensors are best-in-class current sensors for use with power meters, Memory HiCorders and high performance oscilloscopes. The CT6844 is a high-precision 500 A AC/DC current probe that features a wide operating temperature range and large jaw diameter, making them ideal for evaluating the operational integrity of devices that are subject to extreme temperature ranges.

Use with an instrument with a high input impedance of 1 MΩ or higher.

High-accuracy current sensors ideal for use with oscilloscopes and power meters

Compared to current sensors that use Hall elements, flux gate type current sensors are not prone to measurement error caused by variations in the external temperature. In addition, they can measure extremely low input (current values) and current waveforms with phase that lags by 90° with a high degree of precision. The CT6840 Series AC/DC Current Probes are ideal for measuring power waveforms with a digital oscilloscope and power meters.

Key Features

- Frequency bandwidth DC to 500 kHz, Rated current 500 A AC/DC

- High-precision measurement of charge and discharge efficiency of EV batteries

- High-precision measurement of DC power of PV power generation systems

- Ideal for use in environmental testing with broad -40°C to 85°C temperature range

- Single-handed operation and robust locking mechanism

- High accuracy (amplitude): [DC]±0.22%, [50/60 Hz]±0.21%

High accuracy (phase): [50/60 Hz]±0.1°

Model No. (Order Code)

| CT6844 | To Be Discontinued, 500 A AC/DC, PL23 terminal |

|---|---|

| CT6844-05 | 500 A AC/DC, ME15W terminal |

A comment from the Good Design Award 2016

“The ergonomic design of these products appropriately reflects conditions in the field as well as worker needs through features such as one-handed operation and a grip that can be easily opened and closed in any orientation. In addition, they exhibit a high level of overall finish, including through the effective use of visual cues, for example use of yellow and gray to prompt the user to interact with the instrument in a way that avoids its inherent hazards.”

Germany iF Design Award

Ideal for thermostatic chambers and engine rooms

The CT6844 series is ideal for operational evaluations of devices inside equipment that is subject to extreme temperature changes, offering tough, high-precision testing thanks to its broad temperature characteristics and an operating temperature range of -40°C to 85°C. The clamp sensor's tough performance helps ensure you can make the measurements you need.

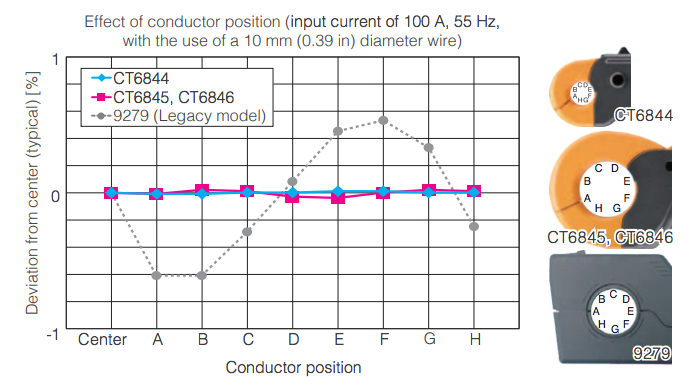

Minimal effect from conductor position

When using typical clamp sensors, careful attention must be paid to the position of the conductor being measured because a break in the magnetic core makes it difficult to obtain uniform characteristics around the entire circumference of the core. The CT6844 series leverages Hioki's core competency in current sensing technologies to deliver almost no effects from conductor position, letting you position the cable under test anywhere within the clamp and still achieve the defined accuracy.

Basic specifications

| Rated current | 500 A AC/DC | |||||

|---|---|---|---|---|---|---|

| Frequency bandwidth | DC to 500 kHz | |||||

| Diameter of measurable conductors | Max. φ 20 mm (0.79 in.) | |||||

| Max. allowable input | ±800 Apeak (Within 20 ms in an environment of 40°C/104°F or less) |

|||||

| Output voltage | 4 mV/A | |||||

| Output resistance | 50 Ω ± 10 Ω | |||||

| Accuracy (amplitude) ±(% of reading + % of full scale) |

DC: 0.2% + 0.02% DC < f ≤ 100 Hz: 0.2% + 0.01% |

|||||

| Linearity | ±20 ppm Typical | |||||

| Common-Mode Voltage Rejection Ratio (CMRR) |

DC to 1 kHz:150 dB or greater 1 kHz to 10kHz:135 dB or greater 10 kHz to 100 kHz:120 dB or greater 100 kHz to 300 kHz:100 dB or greater (effect on output voltage and common mode voltage) |

|||||

| Automatic phase correction | Automatically performs phase correction when connected to PW8001 | |||||

| Operating temperature, humidity | -40°C to 85°C (-40°F to 185°F), 80% RH or less | |||||

| Standards | Safety IEC 61010-2-032:2012/EN 61010-2-032:2012 Type D EMC IEC 61326-1:2012/EN 61326-1:2013 |

|||||

| Withstand voltage | AC 4,260 V | |||||

| Rated power supply voltage | ±11 V to ±15 V | |||||

| Max. rated power | 7 VA or less (When measuring 500 A/55 Hz with ±12 V power supply) | |||||

| Dimensions and mass | Approx. 153 mm W × 67 mm H × 25 mm D (approx. 6.02 in. W × 2.64 in. H × 0.98 in. D), 400 g (14.1 oz.) |

|||||

| Cable length | Approx. 3 m (9.84 ft.) | |||||

| Included accessories | ・Markup bands(×6) ・Carrying case ・Instruction manual |

|||||

Compatible models

| Compatible models | CT6844 (To Be Discontinued) | CT6844-05 | ||||

|---|---|---|---|---|---|---|

| Power Analyzer PW6001, PW3390 |

△ (Requires CT9900) | OK | ||||

| Power Analyzer 3390 |

OK | △ (Requires CT9901) | ||||

| Power HiTester 3193 series |

OK | △ (Requires CT9901) | ||||

| Current Unit 8971 |

△ (Requires the 9318) | △ (Requires the 9318, CT9901) | ||||

| F/V Unit 8940 |

△ (Requires the 9318, 9705) | △ (Requires the 9318, 9705, CT9901) | ||||

External power supply, connection cord (5)

Cord has insulated BNC connectors at both ends, 1.6 m (5.25 ft) length

Cord has metallic BNC connectors at both ends, use at metallic terminal, 1.5 m (4.92 ft) length

Options B (1)

Cannot be used in combination with the 9277, 9278, 9279

Convert PL23 (10-pin) terminal to ME15W (12-pin) terminal

Conversion cable/extension cable (1)

The CT9902 connects up to 2 cables in series (Accuracy addition required)

5 m (16.41 ft) length, ME15W (12 pin) - ME15W (12 pin) connector

Options D (1)

For connecting to the F/V Unit 8940 or Current Unit 8971

To connect the CT6841-6846, CT6865/63/62, 9709, 9272-10 to the 8971/40/51, 38 cm (14.96 in) length

- Evaluation of Input and Output Characteristics of Power Conditioners

- Comprehensive Evaluation of Inverter Motors

- Testing System Interconnection Protection Function of Power Conditioners

- Synchronized Input and Output Measurement of Three-Phase Inverters

- Evaluate the Efficiency of a DC-DC Converter with the PW3390 Power Analyzer