Simplify RDE Testing with Seamless Energy Consumption Analysis

Laboratory-based standards such as WLTP (Worldwide Harmonized Light Vehicles Test Procedure) are essential, but they can’t capture the full complexity of how vehicles behave in real-world environments. Urban traffic jams, long highway drives, steep mountain roads—only Real Driving Emission (RDE) testing (or Real-World Range testing for EVs) can reveal the true energy performance and environmental impact of a vehicle. As regulatory frameworks in Europe and other countries increasingly mandate real-road validation for gas-powered vehicles, RDE testing is becoming critical not only for compliance but also for engineering development. Although Real-World Range testing is not mandatory for EVs, there is a growing trend toward placing greater emphasis on actual energy consumption for EVs as well.

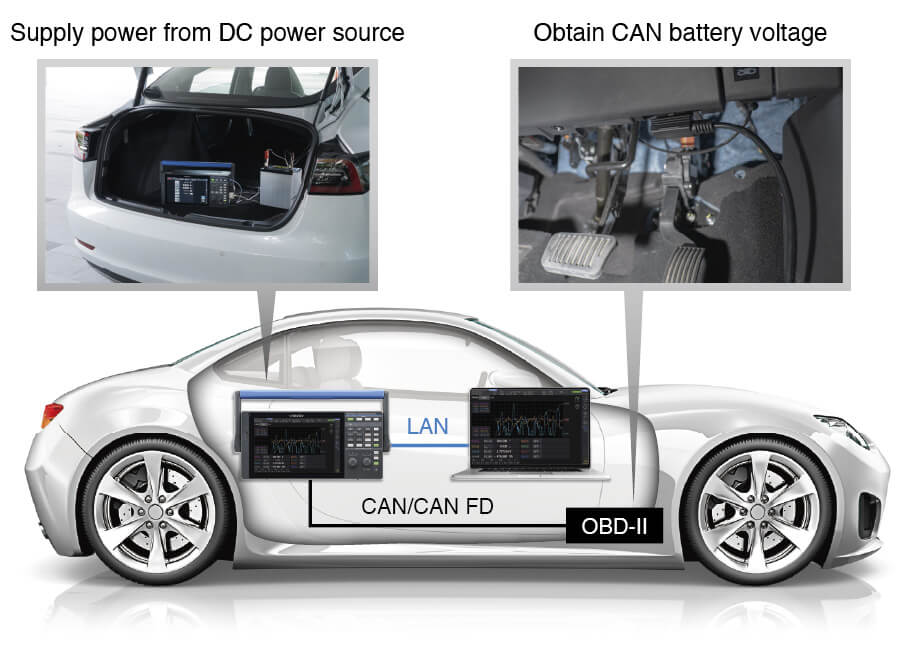

Fig. 1. Vehicle energy consumption and range testing

Challenges: Why Real-World Range Testing Is Not Simple

Real-world testing presents significant obstacles:

- High-precision measurement tools are bulky, but they must fit inside the vehicle during the test

- Test equipment must withstand vibration and temperature shifts

- Diverse data sets—power, current, temperature, and CAN signals—must all be consolidated in one place to find correlations

Case Scenario: an EV Development Team’s Real-Drive Journey

Let’s explore a hypothetical example that illustrates the full potential of Hioki’s solution. A pilot EV departs from a development site for a 75 km test run, across city areas, suburban roads, and highways.

The engineering team faces three main goals:

- 1.Ensure both accuracy and safety for measuring battery power consumption

- 2.Understand differences between actual energy efficiency and catalog specifications in city areas, suburban areas, and highways

- 3.Track current consumption from air conditioning system

Fig. 2. RD test for EVs

Test Setup: Behind-the-Scenes of Real-World Measurement

For power consumption analysis, the PW4001 Power Analyzer is installed using clamp sensors that can be safely attached even in narrow spaces underneath the vehicle.

Fig. 3 Engineer attaching the CT6834 current sensor between the battery and the eAxle under the car

The PW4001 calculates real-time power by combining voltage data via CAN readings with current data from clamp sensors—no risky direct connection to high-voltage terminals.

Fig. 4. Engineer sending CAN IDs of the DBC file to the PW4001 inside the car

To measure Air conditioner’s current, compact CT6831 AC/DC sensors capture even minute fluctuations in power consumption.

Fig. 5. Ultra-compact AC/DC current sensor CT6831 attached in the vehicle’s dense wiring

Dynamic Data During the Drive

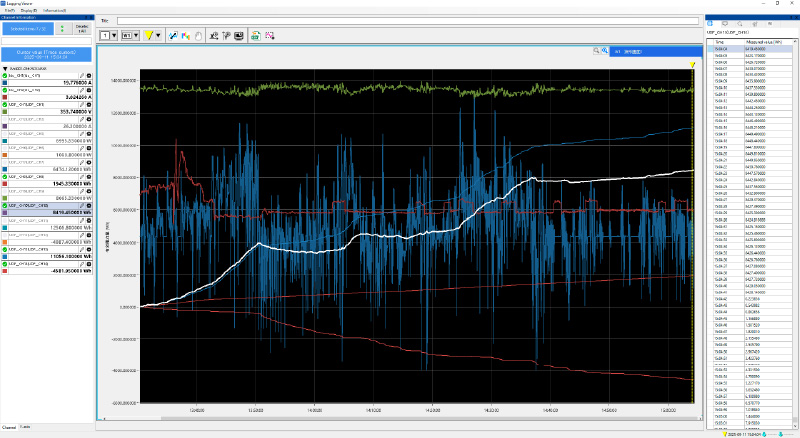

Throughout the test, engineers monitor all measurements in real time using the GENNECT ONE software (Fig. 6).

Fig. 6. Energy consumption test result (all measurements)

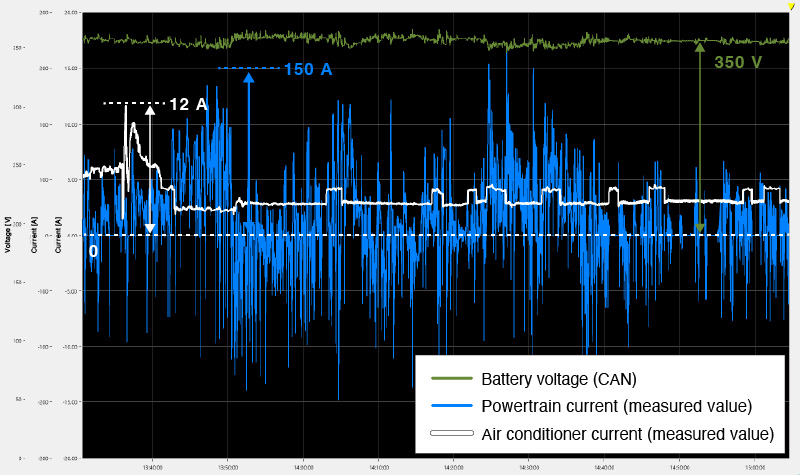

During the first 15 minutes of driving, the current consumption of the air conditioning system is relatively high to cool the interior of the car. However, after the interior of the car is cooled, the air conditioning current is nearly stable (Fig. 7).

Fig7. Energy consumption test result (voltage and current)

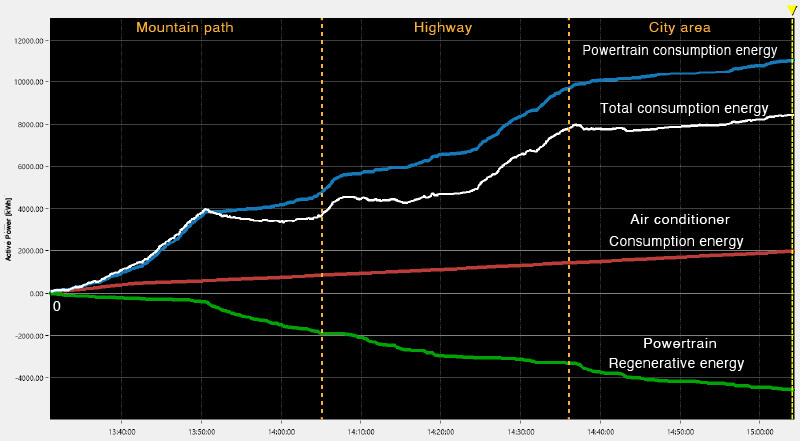

Regarding energy consumption, a significant amount of energy was used on mountain roads and highways. However, the actual energy consumption on the highway turned out to be better than the catalog specifications. This is believed to be due to the fact that the course this time was predominantly downhill. Similarly, for city areas, as most of the course was downhill, energy consumption was remarkably low (Fig.8, Table 1).

Fig. 8. Energy consumption test result (energy)

Table1: Energy consumption test result (energy efficiency)

| Area | Consumption energy (distance) | Energy efficiency |

|---|---|---|

| Mountain path | 3.669 kWh (23 km) | 159 Wh/km |

| Highway | 4.298 kWh (42 km) | 102 Wh/km |

| Urban area | 0.462 kWh (11 km) | 42 Wh/km |

The powertrain consumes 11 kW of energy, but approximately 40% of that, which is 4.5 kW, was recovered (Table 2).

Table2: Energy consumption result (consumption energy and regenerative energy)

| Parameter | Result |

|---|---|

| Wh_Powertrain (consumption) | 11.078 kWh |

| Wh_Powertrain (regenerative) | -4.581 kWh |

| Wh_AirCinditioner (consumption) | 1.948 kWh |

| Wh_Total (consumption) | 8.444 kWh |

Fig. 9. Engineer reviewing real-time test data on in-vehicle laptop screen

Post-Test Data Utilization

After the drive, engineers upload the collected data to a central server. GENNECT ONE allows intuitive correlation analysis between voltage, current, power, energy, and CAN signals. For instance:

- Differences between actual energy efficiency and catalog specifications in city areas, highways and other roads

- Energy-saving effects when the air conditioner is set to AUTO mode

- The ratio of consumption energy to regenerative energy in the powertrain

These insights drive improvements in control algorithms and thermal design for the next vehicle iteration.

Why Hioki’s Integrated Solution?

Hioki brings unmatched value to real drive test environments through:

- PW4001:

High-accuracy power measurement, and safe non-direct connections - CT6834:

Precision clamp-type current sensor, making for reliable data - CT6831:

Minute current fluctuations are reliably captured - GENNECT ONE:

Unified software platform that accelerates data analysis

Conclusion

Real drive testing isn’t just about regulatory compliance—it’s a vital gateway to unlocking the true performance potential of next-generation vehicles.

Compact, rugged, and precise—Hioki’s measurement tools are purpose-built for the challenges of in-vehicle measurement.

For detailed product information, please visit our website.

For a demonstration or consultation on a specific application, please contact us.