Streamline testing with WLTP-defined measurement methods

Reducing the burden of test preparations while satisfying WLTP accuracy requirements with a clamp-type current sensor and power analyzer that are used by certification organizations

Featured customer

Company Z, a major European automaker, has worked to design vehicles that suit the tenor of the times with a flexible approach that’s informed by early awareness of customer needs and lifestyles. In recent years, the company has earned high praise in the global market by dedicating resources to increasing the energy-saving performance of its small and medium-size automobiles.

Background

Searching for more accurate current measurement to comply with the WLTP international standard

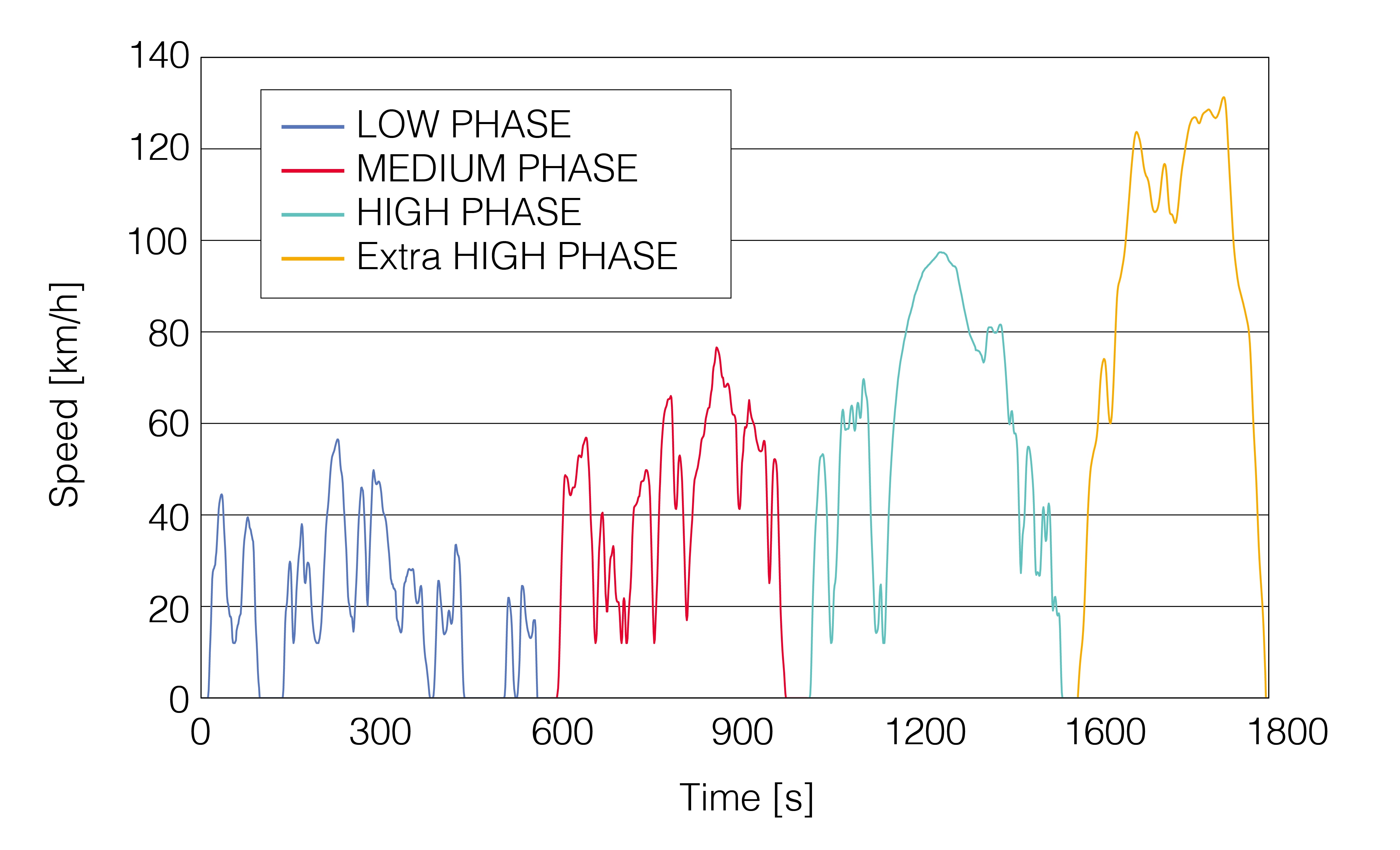

Until recently, emissions and fuel efficiency test cycles and testing methods for automobiles were governed by an array of national and regional regulations, making it necessary for automakers to carry out a separate testing regime for each country or region in order to certify their products. The Worldwide harmonized Light vehicles Test Procedure (WLTP), a unified global standard, was developed to resolve this problem. The European Union introduced the Worldwide Light-duty Test Cycles (WLTC) mode under the WLTP in 2017, as did Japan in 2018.

Test Cycle Example

Test Cycle Example

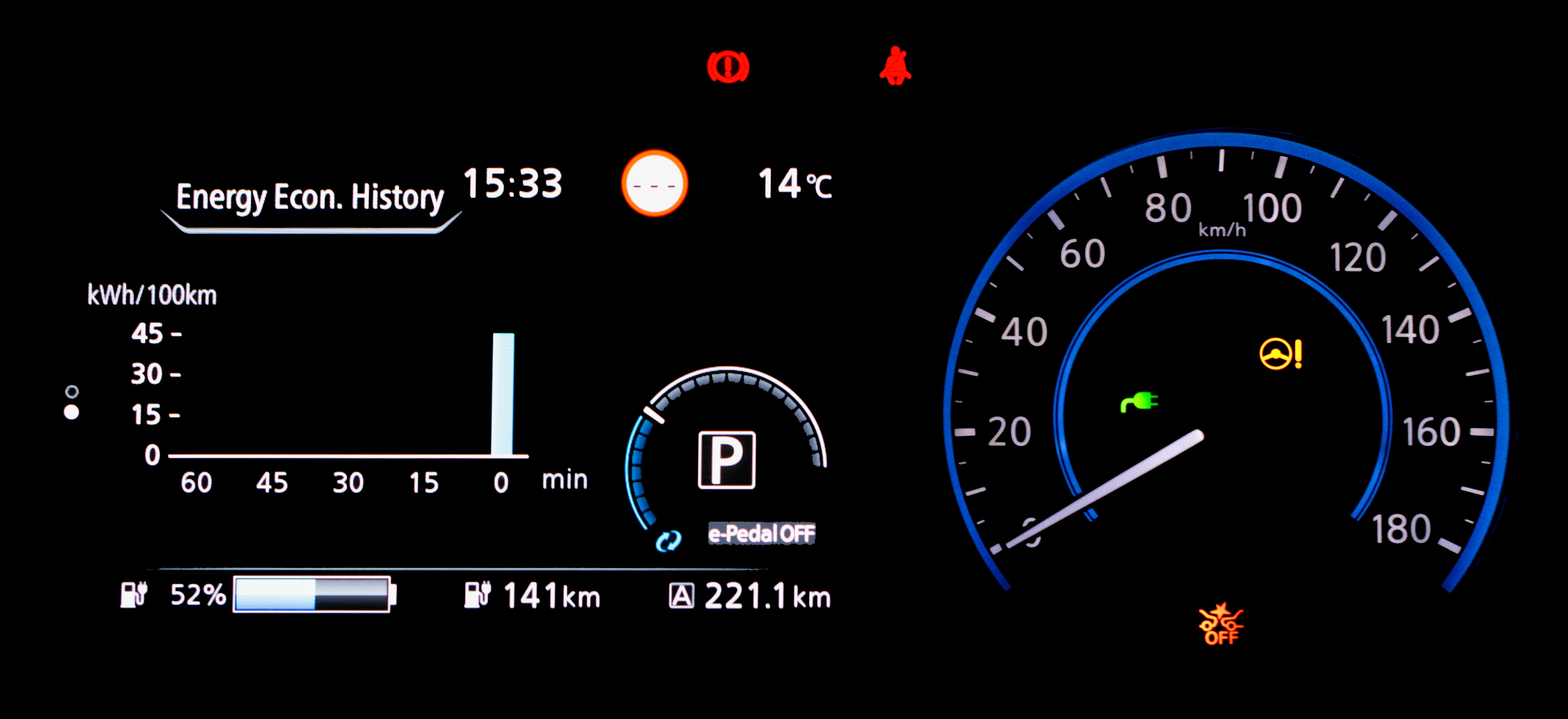

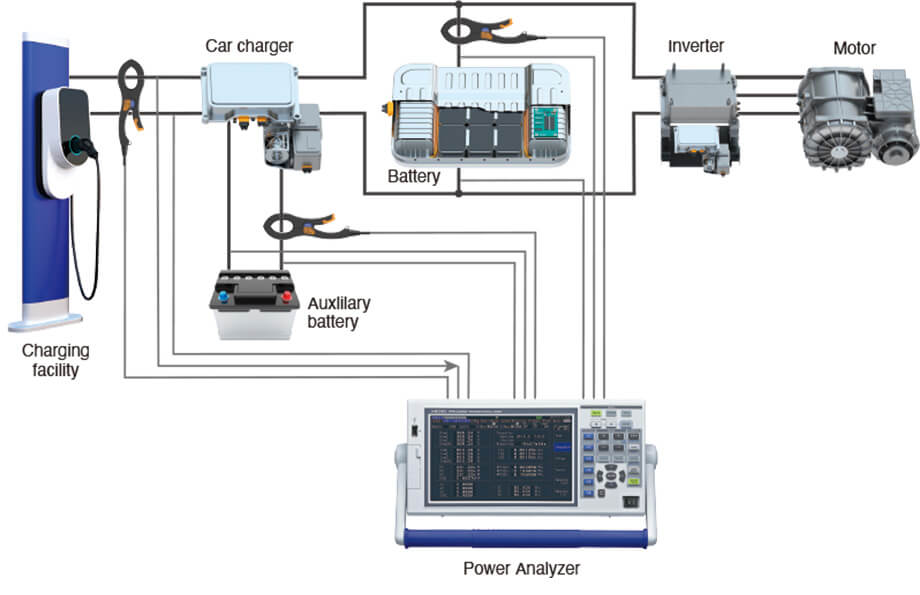

The standard requires testers to measure the electrical energy used in the charging and discharging of batteries in vehicles and convert it to CO2 emissions. As a result, the model certification process requires manufacturers to convert electrical energy, making it necessary for them to accurately measure voltage, current, and power. Since the results of measurements made as part of certification testing may be published in catalogs and other materials, automakers and automotive part manufacturers are working to establish better measurement methods so that they can conduct certification-oriented measurement starting during the development stage.

Company Z, which offers numerous models for sale in Europe and other markets worldwide, is reexamining conventional measurement methods to ensure that the rigorous requirements imposed by the WLTP are being satisfied. The company has worked to reassess instruments so that voltage, current, and power can be measured with a high degree of precision, even in vehicle development.

Key considerations that led the customer to choose Hioki

A clamp-type current sensor that satisfies the WLTP’s rigorous accuracy requirements

In the course of investigating how it could make measurements more accurately, Company Z ran headlong into the difficulty of current measurement, a process that uses either pass-through or clamp-style current sensors. Generally speaking, pass-through current sensors offer higher measurement accuracy. However, such devices make it necessary to disconnect the wire being measured, route it through a ring-shaped sensor, and then revert the wire to its original state after measurement. Such work takes up valuable man-hours and invites unforeseen challenges while disconnecting and reconnecting wires.

Pass-through current sensors

Pass-through current sensors

By contrast, clamp-type current sensors consist of a ring-shaped sensor that opens and closes so that it can be clamped around the wire being measured. They’re easy to use and don’t require wires to be disconnected prior to measurement. However, their design results in an inevitable gap in the magnetic material where the sensor opens and closes, reducing their accuracy compared to pass-through models. Consequently, Company Z was having difficulty finding a sensor that provided the level of current accuracy required by the WLTP. In this way, the two types of current sensors have their respective advantages and disadvantages. The company wished to minimize modification of completed vehicles to ensure accuracy, and it wanted to measure fuel efficiency more accurately with easy-to-use clamp-type current sensors.

Clamp-type current sensors

Clamp-type current sensors

Open Clamp-type current sensors

Clamp-type current sensors

Closed

Technology that Supports the Evolution of Current Testing

Technology that Supports the Evolution of Current Testing

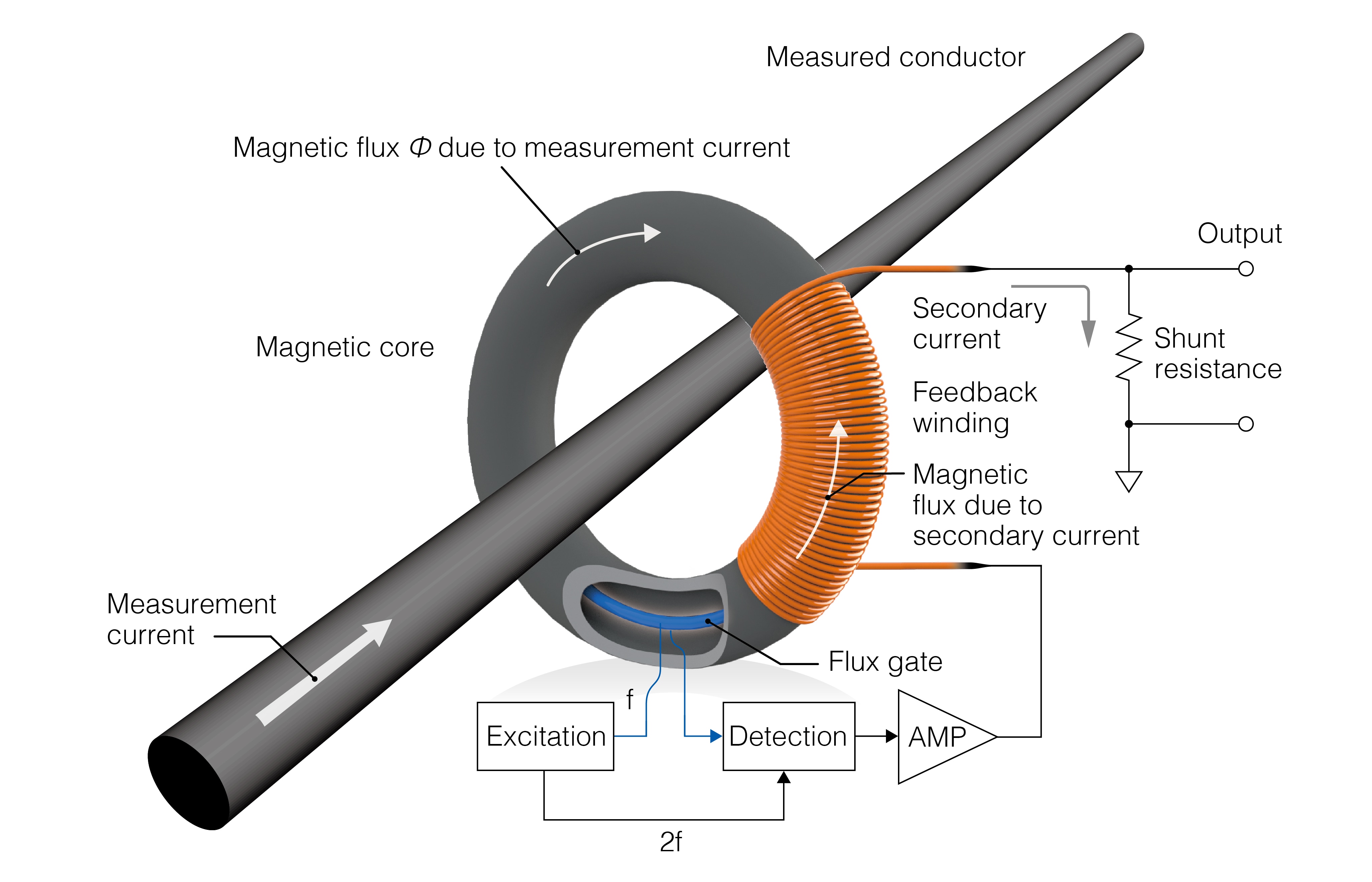

"zero flux method (flux gate detection type)"

Company Z made an inventory of the many clamp-style current sensors that are available in the market. Through this comparison, it identified the combination of a Hioki AC/DC current probe and power analyzer as an instrument that would satisfy the WLTP’s rigorous accuracy requirements. Since both products are developed and manufactured in-house by Hioki, they’re designed to provide superior measurement capability when used in combination, including in terms of noise measures. Company Z quickly decided to purchase these products after several tests.

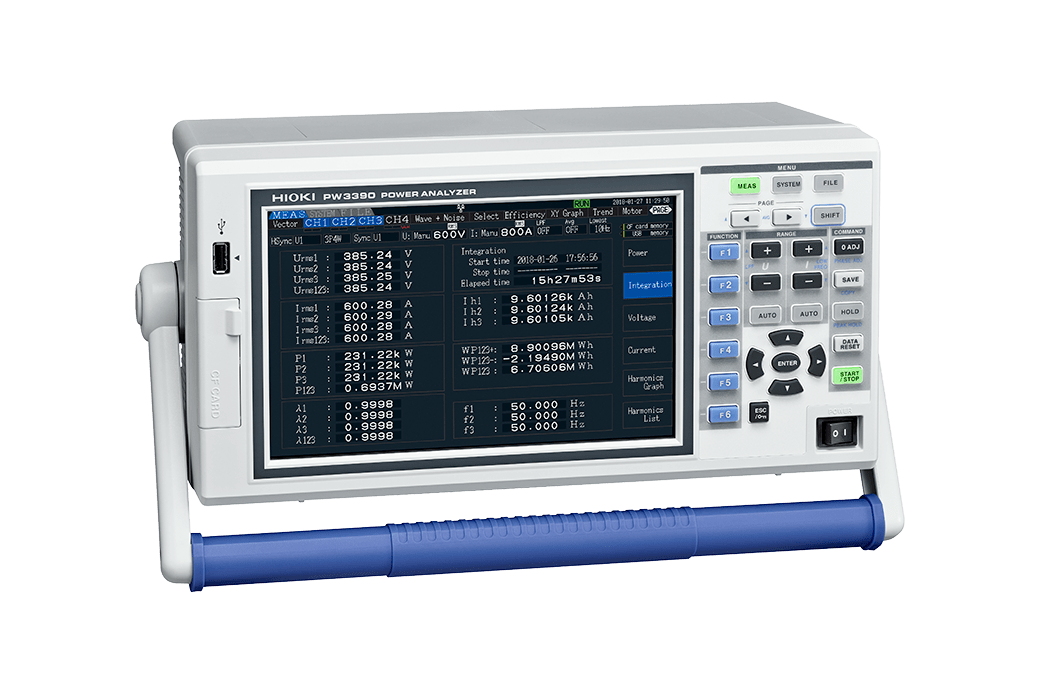

The speed of Company Z’s purchase decision reflected the fact that Hioki offers an extensive line of current sensors with different current ratings. The company was impressed by the ability to choose the current sensor with the optimal rating based on the current capacity of the vehicle being measured, and by the ease with which sensors can be changed. Reflecting its desire for a power analyzer that could be carried between various locations, it also chose the PW3390, whose compact size, excellent portability, and high accuracy perfectly fit the bill.

Power Analyzer PW3390

Power Analyzer PW3390

Current Sensors

Current Sensors

Benefits

Testing with fewer man-hours and greater peace of mind thanks to accurate measurement using clamp-style current sensors

By deploying AC/DC current probes and the Power Analyzer PW3390, Company Z is able to satisfy the WLTP’s rigorous current accuracy requirements with a minimal workload—technicians only need to clamp current sensors around the wires being measured. Since even finished test vehicles can be measured without disconnecting wiring, the automaker has been able to minimize the preparatory work required in advance of fuel efficiency testing.

In principle, WLTP certification testing is carried out at a certification organization’s facility or at the automaker’s facility in the presence of an inspector from the certification organization. The combination of AC/DC current probes and the PW3390 is used by many certification organizations. For Company Z, deploying the same equipment as those organizations allows it to repeat measurements from the development stage with peace of mind and to undergo certification testing with confidence in the results.

Recently, a part manufacturer working with Company Z is considering deploying AC/DC current probes and the PW3390 so that they can accurately evaluate the fuel efficiency gain when vehicle parts are replaced with their latest designs and then propose those benefits to Company Z. Since Company Z can use such parts with confidence and peace of mind, more part manufacturers can be expected to adopt this approach in the future.

The WLTP, which is conceived to offer milage estimates that closely approximate what drivers can expect during actual driving, continues to undergo revision. In 2021, low-temperature testing conditions were added to require calculation of fuel efficiency at -7°C. Company Z immediately complied with this low-temperature testing requirement. By working with Hioki, the company was able to broaden the Power Analyzer PW3390’s operating temperature range to -10°C to 40°C (from the original range of 0°C to 40°C). Going forward, the automaker plans to collaborate with Hioki to comply with fuel efficiency regulations, which are expected to undergo a series of ongoing revisions, in a flexible manner.