Ensuring Uninterrupted Power: Effective Strategies for UPS Operation Testing

MR8848-Enabled Preventing Data Loss: How to Test UPS Systems for Reliable Power Backup

Imagine a sudden power outage disrupting your business operations or daily life. Computers crashing, losing critical data, or production lines grinding to a halt—these scenarios highlight the vital role of uninterruptible power supplies (UPS). These devices instantly provide backup power when the main supply fails, protecting essential equipment and processes. From offices and retail stores to data centers, medical facilities, and factories where downtime is unacceptable, UPS systems are indispensable. They prevent data corruption in servers and ensure life-saving medical devices remain operational. The Memory HiCorder captures real-world UPS setups in critical environments like data centers for seamless integration.

In an era of increasing extreme weather, lightning strikes, and grid instabilities due to climate change, relying on UPS without verification is risky. Batteries degrade over time, potentially leading to failures like smoke or fire hazards. Regular testing using the MR8848 Memory HiCorder confirms that your UPS will perform when needed, averting system crashes, equipment damage, and financial losses. By focusing on waveform analysis, users gain clear insights into voltage and current stability, timing precision, and overall health—empowering proactive maintenance for peace of mind and operational continuity.

The Critical Need for UPS Verification

Global warming and erratic weather patterns have amplified the frequency of power disruptions, making UPS reliability more crucial than ever. Neglecting routine checks can result in severe consequences: data loss, operational halts, or even fire risks from faulty units. Instead of assuming functionality, users benefit from empirical validation, ensuring the system switches seamlessly during outages. The MR8848 enables this confirmation with its high-speed waveform observation, preventing risks like data loss from unverified battery degradation.

The Effectiveness of Waveform-Based UPS Diagnostics

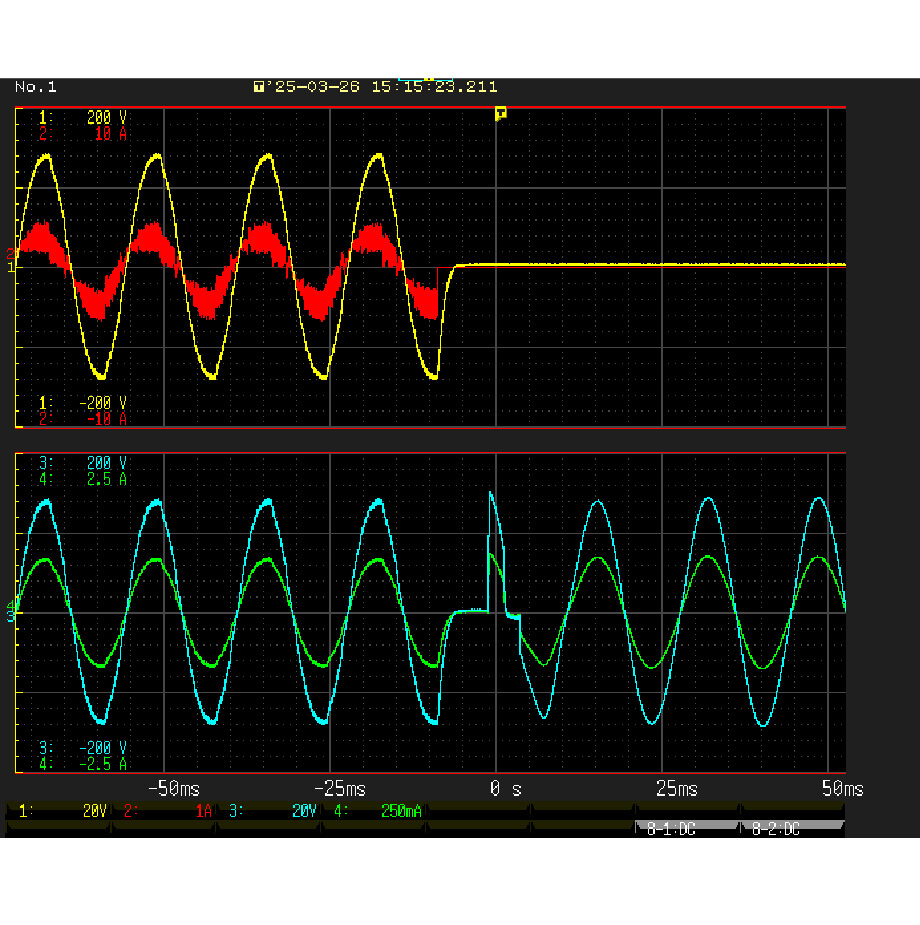

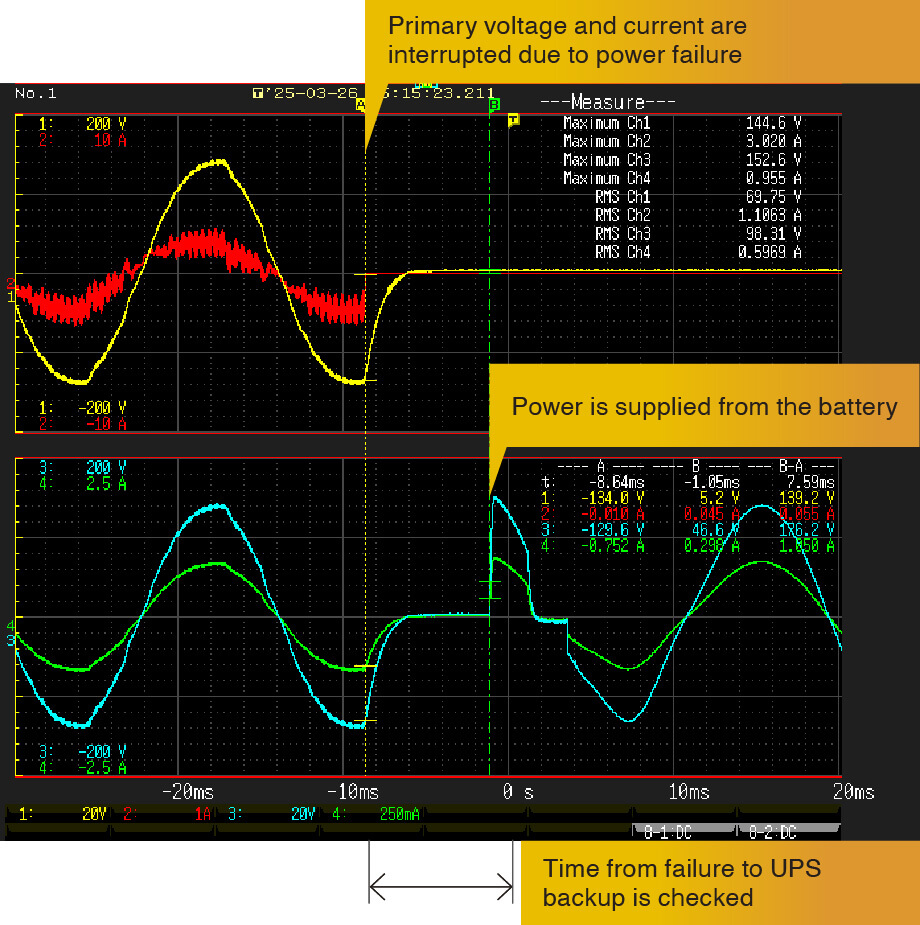

Waveform observation stands out as an efficient diagnostic tool. By monitoring output voltage and current waveforms, you can detect anomalies indicating internal issues or load mismatches. This method also reveals the exact timing of power transitions, highlighting any delays that could affect sensitive equipment. Visualizing these dynamics allows for deeper insights, enabling timely interventions that extend UPS lifespan and enhance safety.

Effective Testing Methods for UPS Systems

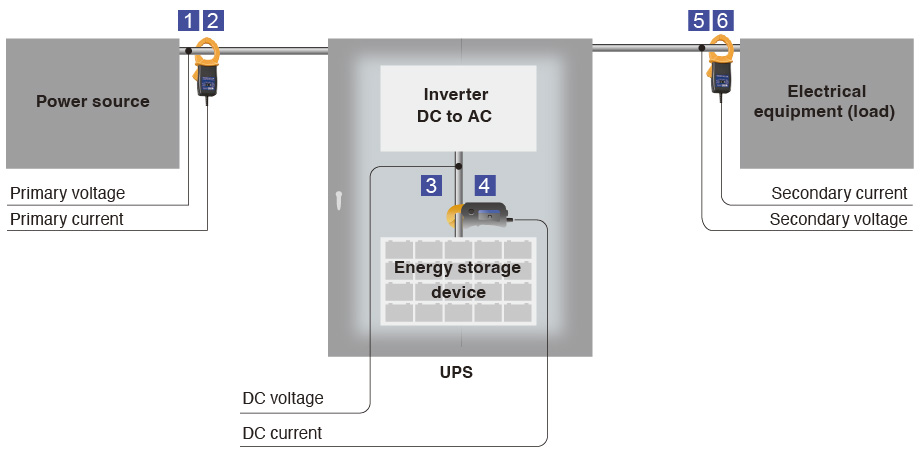

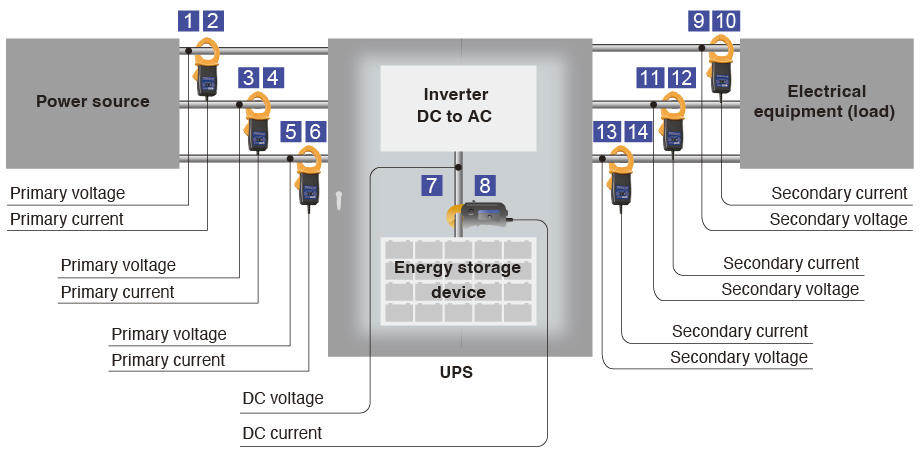

To verify UPS operation, simulate outages and measure key parameters across single-phase or three-phase setups. Connect voltage probes to the primary (input) and secondary (output) sides, use current sensors for amperage while monitoring battery voltage and internal temperatures. This multi-channel approach captures the full behavior of UPS operation during power failure and recovery.

Hioki's MR8848 Memory HiCorder stands out here, offering 20 MS/s sampling across 16 channels to overlay voltage, current, and temperature waveforms—ideal for spotting outage transition lags in single- or three-phase systems.

For Single-Phase UPS

For single-phase UPSs, voltage and current waveforms must be simultaneously recorded from its input and output, and from the battery. This reveals transition lags and instability, helping identify noise or harmonic distortions from the grid. High-speed sampling is essential to catch these transient events accurately.

Measured phenomena on 6 or more channels

- Primary side: voltage 1 ch, current 1 ch

- Secondary side: voltage 1 ch, current 1 ch

- Energy storage device: voltage 1 ch, current 1 ch

- Temperature or other phenomena (channel number depends on measurement objects and module limitations)

For Three-Phase UPS

In three-phase configurations, assign a separate measurement channel (i.e., a logical software channel) for each phase's voltage and current on both the primary and secondary sides, and add any additional channels for the inverter-battery interaction and temperature. Influences from commercial power like spikes demand fast recording to ensure comprehensive analysis.

Measured phenomena on 14 or more channels

- Primary side: voltage 3 ch, current 3 ch

- Secondary side: voltage 3 ch, current 3 ch

- Energy storage device: voltage 1 ch, current 1 ch

- Temperature or other phenomena (channel number depends on measurement objects and module limitations)

The MR8848's 20 MS/s sampling across up to 16 isolated analog channels ensures comprehensive multi-parameter monitoring on a unified graph.

Conclusion

UPS systems do more than supply power; they uphold business continuity, data integrity, and safety in an unpredictable world. Regular waveform-based testing ensures these guardians perform flawlessly, protecting against the hidden threats of degradation and faults. Embrace this method to visualize and verify operations, turning potential vulnerabilities into strengths. The MR8848 simplifies these verifications, making them precise and effortless.

Ready to elevate your UPS testing? Explore Hioki's solutions for precise, multi-parameter measurements that deliver actionable insights. Visit our website for detailed product information and resources to get started today—secure your operations with confidence.

Recommended Measurement Configuration

- Memory HiCorder MR8848

- Analog Unit 8966 for voltage measurement

- 3CH Current Unit U8977 for current measurement

- Temperature Unit 8967 for thermal monitoring

- AC/DC Current Probe CT6843A and Clamp-On Sensor 9272-05 for accurate current sensing

For detailed product information, please visit our website.

For a demonstration or consultation on a specific application, please contact us.