Improving Motor Testing Lines with Economical Partial Discharge Testing

Motor production process and testing

The motor production process incorporates various types of testing, such as:

- Stator winding testing (conducted after the windings are attached to the stator core)

- Stator assembly testing (conducted once the stator assembly is complete)

- Finished product testing (conducted once the parts have been assembled to complete the production of the motor)

To ensure high motor quality, numerous tests and inspections are carried out during each step of the manufacturing process prior to each motor being shipped as a finished product.

Challenges of integrating PD testing and multi-motor testing

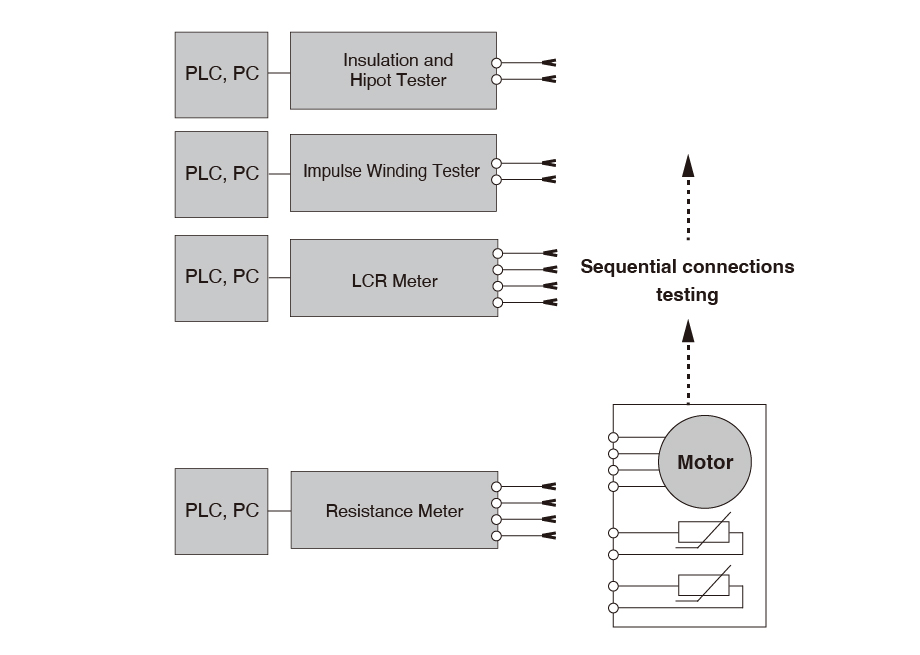

The current testing process involves a series of sequential tests, each requiring time for completion (Fig. 1). The addition of partial discharge testing will inevitably increase the overall testing duration. Furthermore, the need to physically relocate motors between test stations for each test adds significant handling time, further impacting overall efficiency. Implementing an automated testing system that can perform multiple tests at a single location simultaneously has the potential to mitigate these challenges, however, the development and implementation of such a system presents significant cost and design hurdles.

Fig. 1 Current testing line

Flexible system integration for efficient motor testing

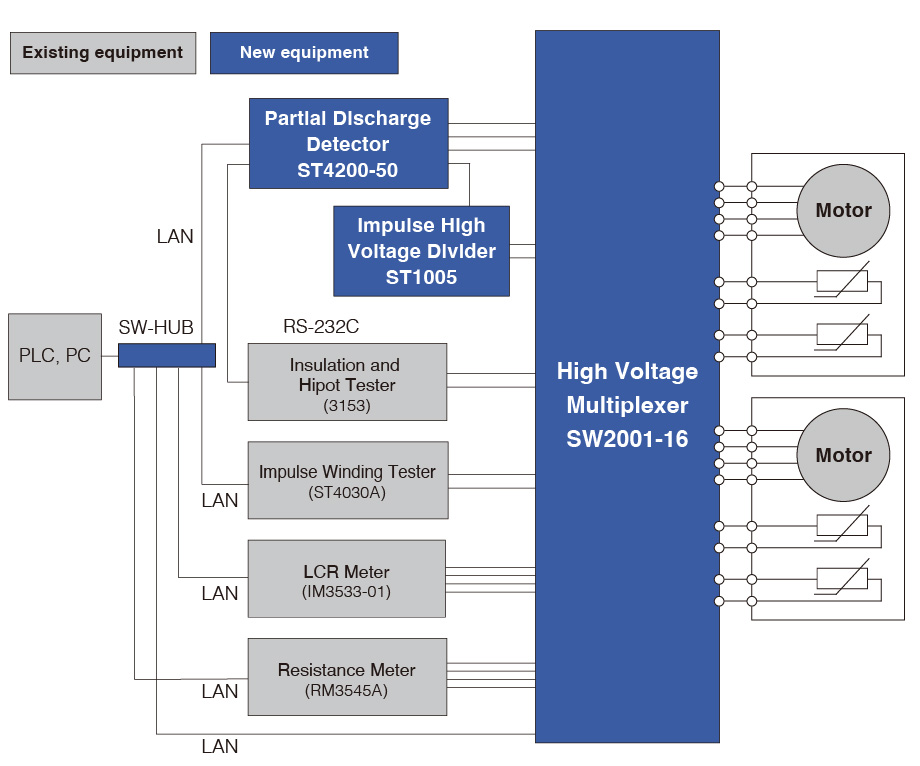

The ST4200, being an independent partial discharge detector without a built-in high-voltage AC source and surge generator, it comes at a more affordable price. This allows users to leverage their already owned hipot testers (e.g., Automatic Insulation/Withstanding HiTester 3153) or impulse testers (e.g., Impulse Winding Tester ST4030A) as high-voltage sources for partial discharge testing. This also eliminates the need to purchase separate PD testing equipment for AC PD testing and surge PD testing. Such a switching system for multiple motor tests would be very difficult and expensive to design and manufacture in-house. However, Hioki's High Voltage Multiplexer SW2001 excellently facilitates these motor stator tests. It is equipped with built-in partial discharge sensors and enables automated switching between test points. Furthermore, this multiplexer is designed for both high-voltage and 4-terminal low-voltage testing, enabling the integration of all stator tests. As explained in the example below, the SW2001-16 model, with its 16 channels, allows for simultaneous testing of up to two finished motors.

Partial Discharge Detector ST4200

Partial Discharge Detector ST4200 High Voltage Multiplexer SW2001

High Voltage Multiplexer SW2001

Motor testing system utilizing ST4200 and SW2001

The chart below illustrates a motor testing system using the ST4200 and SW2001 to enhance production efficiency. To streamline static testing across three finished motors, you can integrate a resistance meter (e.g., RM3545A), LCR meter (e.g., IM3533-01), impulse winding tester or surge tester (e.g., ST4030A), hipot tester (e.g., 3153), and the Partial Discharge Detector ST4200 with the High Voltage Multiplexer SW2001-24. By repurposing existing hipot and surge testers as the high-voltage source for partial discharge testing, you can incorporate this crucial test at minimal additional cost. The system's integration with the SW2001-24 significantly reduces testing cycle times for multiple motor testing, enabling high-throughput production.

Fig. 2 Automated testing line with additional partial discharge testing step

In conclusion, incorporating partial discharge (PD) testing not only enhances the quality of motor stators but also enables the potential for the integration of comprehensive stator testing. Hioki's Partial Discharge Detector ST4200 offers a cost-effective solution by utilizing existing hipot and surge testers as voltage power sources. Additionally, the High Voltage Multiplexer SW2001 ensures seamless and economical integration. Through these innovations, Hioki addresses complex industry challenges. For more information, please contact the most suitable Hioki representative via our contact form.