News Nov. 07, 2023

Lithium-Ion Battery R&D Testing

Updates : Nov. 07, 2023

Revolutionizing Lithium-Ion Battery Performance

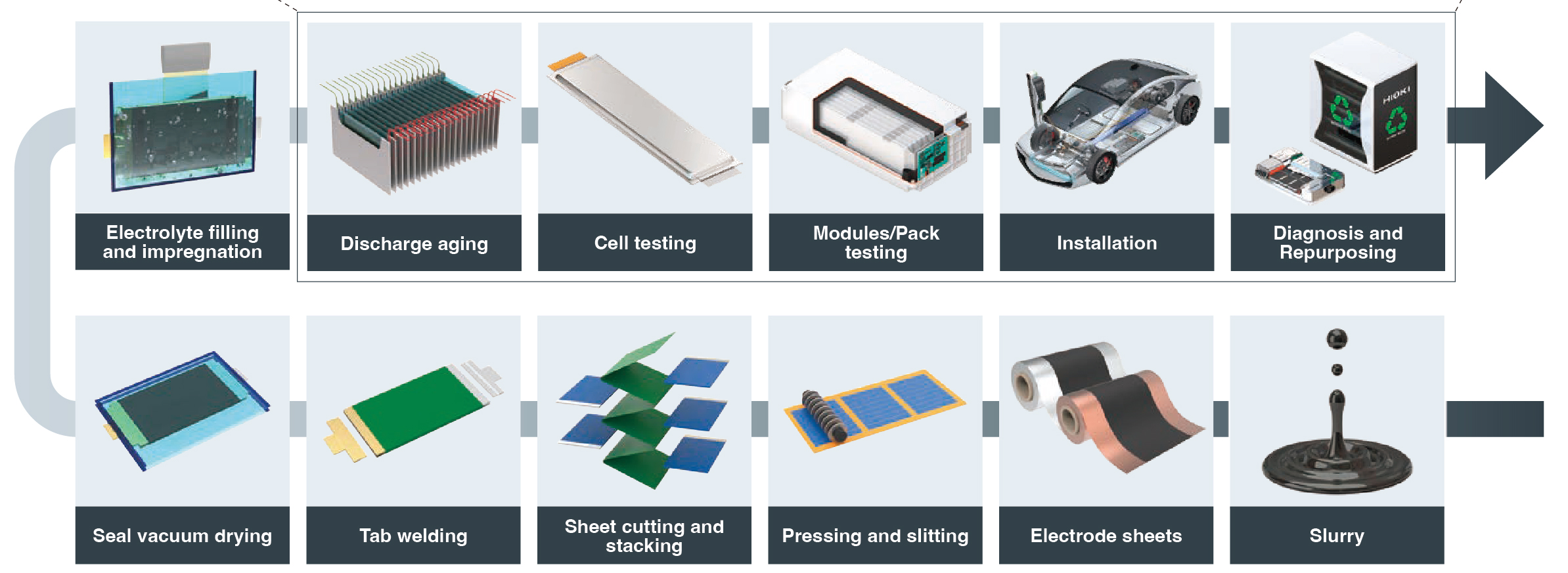

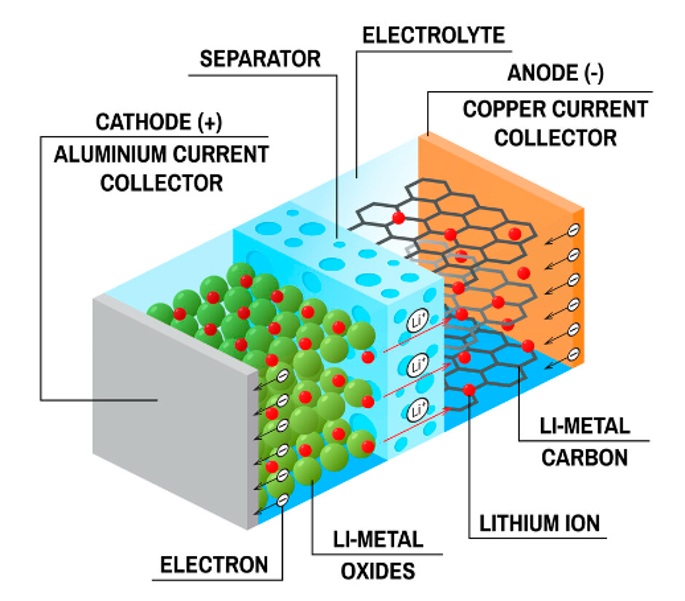

Optimizing the performance of lithium-ion batteries (LiB) by application is a pressing matter in achieving global sustainability goals. Understanding and enhancing the performance of lithium-ion batteries is a complex process that necessitates a deep dive into the battery's design, chemistry, and performance characteristics. It requires meticulous tailoring to ensure that the battery meets the distinct requirements of specific applications.

Key Areas of Research and Development

In this informative platform, we will navigate through key areas of lithium-ion battery research and development.

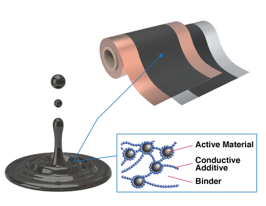

Slurry Analysis

We’ll explore Slurry Analysis, an essential process investigating the homogeneous mixture in the battery's electrodes.

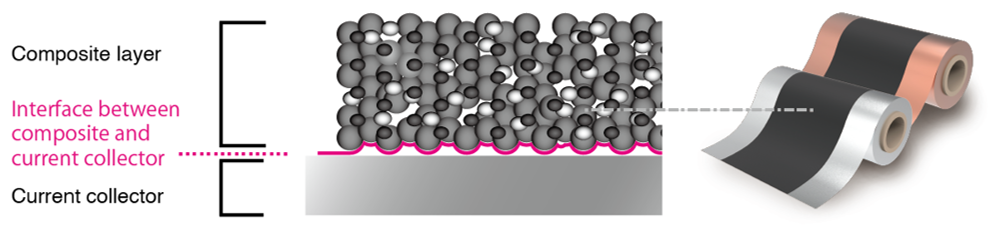

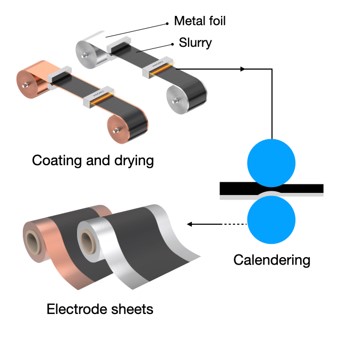

Electrode Sheet Analysis

Then, we’ll delve into Electrode Sheet Analysis, a crucial step that evaluates the quality and performance of electrode sheets used in these batteries.

Correlation Study - Slurry analysis vs. Electrode sheet analysis

Next, we’ll understand the importance of the Correlation Study between Slurry Analysis and Electrode Sheet Analysis. This correlation is pivotal in how the properties of the slurry directly impact the performance of the electrode sheets, which in turn affects the overall performance of the battery.

Battery Characterization

Lastly, we'll focus on Battery Characterization, which involves a series of tests to understand the battery's performance parameters and operation conditions under various circumstances.

Slurry analysis

By examining Nyquist plots or Cole-Cole plots using an equivalent circuit model, one can estimate the slurry’s internal state, including its uniformity and electrical network development. The slurry analytical system was employed in the following case studies to investigate how mixing conditions and formulation affect the formation of the internal state.

Case study

• Differences in mixing time

• Differences in conductive auxiliary agent quantity

• Relationship between electron conductivity and dynamic viscoelasticity resulting from differences in dispersant quantity

Electrode sheet analysis

The resistance of the composite layer and interface resistance can be quantified through inverse problem analysis, which involves curve fitting between the potential distribution computed using the Finite Volume Model (FVM) and the possible distribution measured by a 46-pin test fixture. The research studies below used the RM2610 electrode resistance measurement system to investigate the impact of conductive additives and pressure during calendaring on composite and interface resistance resistivity.

Case study

• Relationship between conductive additive and resistance

• Relationship between electrode density and resistance

Correlation study – Slurry analysis vs. Electrode sheet analysis

Is slurry’s electrical conductivity inherited to electrode sheets? Slurries with different amounts of conductive auxiliary agent were tested with the slurry analytical system and the RM2610.

Battery Characterization

Electrochemical Impedance Spectroscopy (EIS) is a standard technique for battery characterization. With a specially designed multiplexer for impedance measurement, Nyquist plots are collected across multiple battery cells with high speed and high accuracy. Besides battery cell characterization, EIS is used to research performance degradation in battery modules or packs.