Thermal & Energy Management of Electric Vehicles

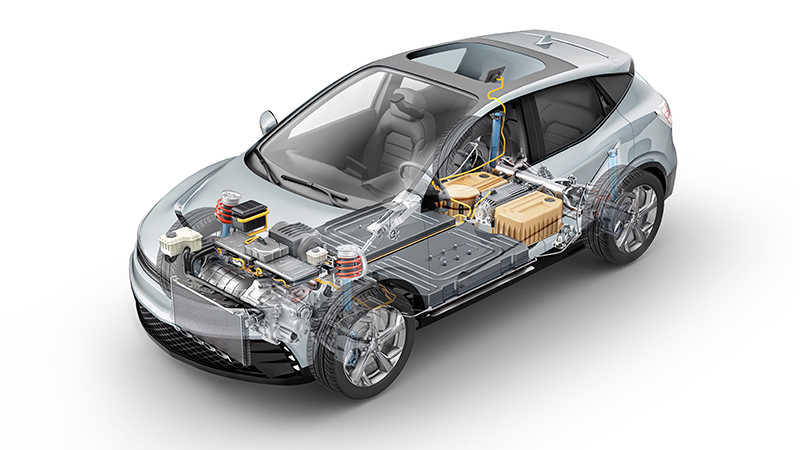

The development of electric vehicles (EVs) prioritizes understanding energy efficiency and power consumption. To achieve this, precise measurement, and analysis of data from various systems, especially batteries, motors, and inverters, are essential. Utilizing high-precision tools such as data loggers and power analyzers enables a thorough understanding of these systems’ performance and facilitates necessary improvements.

Basics of EV Development and Data Collection

Key Points in the Article:

Types of Data Needed and Methods of Measurement

You can understand the significance of measurement data from key vehicle components, such as battery voltage and temperature, motor efficiency, and inverter performance. The article will also explain accurate methods of data measurement using data loggers and power analyzers.

Benefits Gained from This Article:

Discuss how a data-driven approach improves operational efficiency and product quality, focusing on specific benefits like extended range, reduced charging time, and overall energy efficiency improvement. It will provide insights into how collected data can be analyzed and utilized to enhance EV performance. This article delves deep into the importance of data collection in EV development and effective methodologies for doing so.

Essential Data for EV Development

Crucial Steps for Extending EV Range

Battery Charge-Discharge Testing

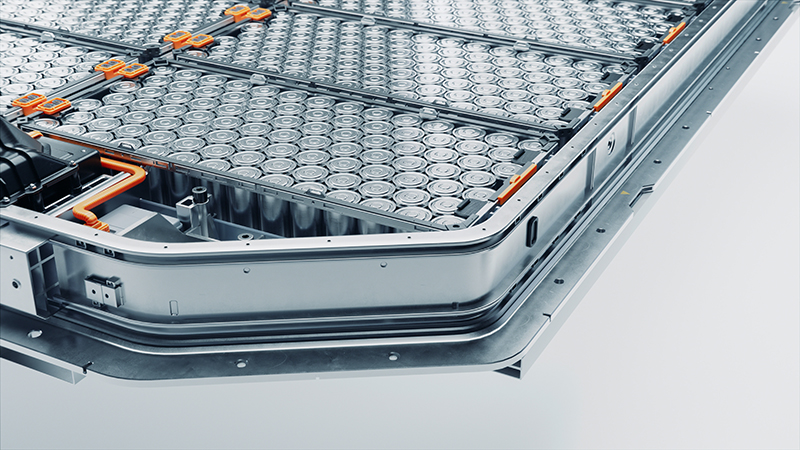

A core aspect of EV development is assessing battery pack performance, primarily through charge-discharge testing. This involves repeatedly charging and discharging the battery pack over a specific period to evaluate its performance, durability, and safety. Accurately recording the battery’s voltage and temperature data during these tests is vital. High-precision data loggers are recommended for this purpose.

Battery Pack Voltage Increase

Extending EV range and reducing charging time is crucial for performance improvement, hinging on increasing battery pack voltage. Accurate measurement of each cell's voltage and temperature during charge-discharge tests is essential, forming the basis for the overall performance assessment of the battery pack. Thus, data loggers used in these tests require specific features like high insulation input, high voltage resistance, and multi-channel functionality. Choosing data loggers designed for high-voltage usage ensures safer and more accurate data collection.

Measuring Battery Pack Cell Voltage and Temperature

In charge-discharge evaluation tests, recording the voltage and temperature helps understand battery characteristics. Battery packs consist of numerous cells connected in series. A single cell's malfunction can lead to overall performance degradation, making it essential to understand each cell's behavior. The voltage of a single cell is around 3.7V, but the data logger's ground potential is subjected to the high voltage of the stacked cells. Therefore, data loggers with high insulation performance are required.

With further increase in battery pack voltage, the number of cells also increases. Therefore, data loggers capable of expanding the number of channels and offering flexible configurations are needed.

HIOKI data loggers, particularly the LR8101 and LR8102 models, provide ideal solutions for measuring high-voltage battery packs in EV development. These models feature modules specialized for high-voltage measurements, capable of handling terminal-to-ground voltages up to 1500V, and can safely measure cell voltages in battery packs exceeding 800V. This capability is particularly important given the contemporary trend of increasing EV battery pack voltage.

Additionally, these data loggers can link measurement modules, offering the flexibility to measure each cell's voltage and temperature accurately and simultaneously monitor multiple battery packs and other electrical components. This scalability is essential for the intricate analysis and optimization of complex EV systems.

Energy Loss in EVs

Managing energy loss is a crucial element in electric vehicles. Besides optimizing the efficiency of crucial components like motors and inverters, understanding DC current (auxiliary DC battery) is necessary to further reduce power consumption. Electrical components in an EV use these DC currents, and their consumption and leakage currents affect the vehicle's overall energy efficiency.

Importance of DC Current

DC current is the lifeline for many electrical components in an EV, including the ECU (Engine Control Unit), wipers, power windows, heaters, headlamps, and cooling fans. Accurately grasping the consumption and leakage currents of these components is vital to minimize energy loss.

Importance and Challenges of Multi-Point Observation

Multi-point observation of consumption and leakage currents requires high-accuracy measurement of DC currents, often in the order of tens of milliamperes. Simultaneously measuring these over long periods is not a trivial task.

HIOKI Data Logger LR8450-01

The HIOKI data logger LR8450-01 is designed to meet such complex measurement needs. This multi-channel data logger, using wireless measurement modules, can be placed near the measurement targets, reducing wiring efforts.

High-Precision Current Sensors

HIOKI’s current sensors CT7812 (2A) and CT7822 (20A) are noted for their compact size. They can easily access complex wiring and efficiently operate in confined spaces like those inside an EV. These tools, capable of high-accuracy measurements, are suitable for onboard measurements and effectively monitor EV energy loss, thereby aiding in improving the overall energy efficiency of the EV.

- AC/DC Current Sensor CT7812 (2A), CT7822 (20A)

Examples of Application EV

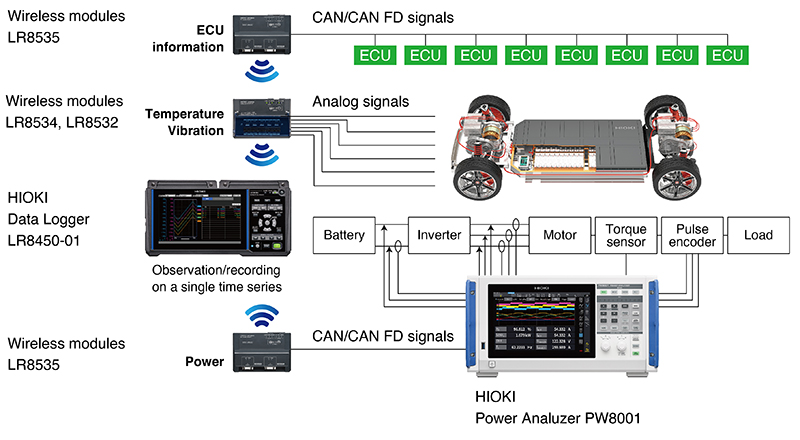

Observation of Vehicle Body CAN Signals and Analog Signals (Temperature and Vibration, and Power Data)

- Efficiency of Motors and Inverters

In EV development, optimizing the efficiency of motors and inverters is key to effectively using limited battery capacity. Here, measuring and analyzing power consumption data using power analyzers is crucial. This data forms the foundation for improving system efficiency.Optimization and Integration of the Entire System

In evaluating xEV systems, efficient energy management of the entire vehicle is required. To achieve this, integrating power data with analog signals like temperature and vibration, along with CAN signals, is important. Integrating these diverse data types enhances the overall system performance and efficiency, leading to extended range and improved ride comfort.Maximizing Efficiency and Performance

Maximizing the efficiency of key components like EV motors and inverters directly relates to overall energy efficiency. Accurately capturing rapidly fluctuating power data and understanding the entire vehicle's state in real-time is key to building an energy-efficient system. Such comprehensive data analysis enables the improvement of EV performance. - Temperature Monitoring

In EVs, temperature significantly impacts range. Specifically, data loggers are used to measure temperature and current, and power analyzers to measure power consumption.Relationship Between Temperature and Energy Efficiency

Temperature management in EVs plays a central role in extending range. Properly controlling the thermal environment of the vehicle (thermal management) optimizes battery efficiency and reduces overall energy consumption.Simultaneity and Integration of Data

Integrating data obtained from data loggers and power analyzers on the same timeline is crucial for devising effective management strategies. Linking data loggers with CAN input and power analyzers with CAN output allows for centralizing diverse data like temperature, current, and power, enabling more accurate analysis.Contributing to Efficiency

Such an integrated data management approach significantly reduces the time spent organizing data, contributing to operational efficiency. Accurate and quick data analysis helps formulate and implement strategies to optimize EV performance and range more swiftly.Temperature monitoring and data integration in EVs play a crucial role in optimizing energy efficiency and extending range. Accurate temperature management and data analysis are key elements for success in EV development.

- Observation of analog signals, CAN signals, and power fluctuations on the same time series

- Example of EV current detection by current sensor and image of data collection of distributed measurement points by wireless measurement module

Benefits of Using Data Loggers in EVs (What Can Be Achieved with Measured Data)

Highly accurate data provides indispensable insights for improving EV performance. Especially using our products ensures precision and reliability in data collection, a significant advantage.

Thermal Management and Battery Voltage for Extending Range

To extend the range of an EV, thermal management is as crucial as battery capacity. The temperature of the battery directly affects its performance. For instance, driving at 30℃ vs. 40℃ can lead to a noticeable difference in range. The ideal battery environment should generally be maintained within 20 to 30 degrees, requiring effective heat management through methods like warming the battery or using liquid or air-cooling systems.

A few percent differences in the measurement accuracy of battery cell voltage can translate into tens of kilometers in range. Therefore, accurately measuring the battery’s voltage is extremely important. Using HIOKI’s high-precision data loggers, such delicate voltage fluctuations can be accurately captured. This allows for identifying optimal operating conditions for the battery, thereby formulating strategies to maximize range.

Optimizing EV Power Management

In the complex electrical systems of electric vehicles (EVs), unexpected power consumption and leakage currents can sometimes occur. These issues can lead to decreased battery efficiency or, in the worst case, pose safety risks. Therefore, it is essential to quickly identify and address these problems. In such situations, the HIOKI LR8450 data logger proves to be an effective tool. The LR8450 is a multi-channel data logger capable of high-precision current measurement, accurately capturing even small changes in current. This allows for the efficient identification of abnormal power consumption and leakage currents within the vehicle's electrical system.

Hioki Products

Conclusion

In this article, we discussed data collection in electric vehicles (EVs) using data loggers and power analyzers. Utilizing HIOKI tools can offer numerous benefits, such as extending the range and improving operational efficiency. For those interested in more detailed information on our products and their applications, please feel free to contact us. Our company, with its rich experience, is ready to support your business..