Insulation Performance Testing of Insulating Materials: An Essential Process for Electric Vehicles

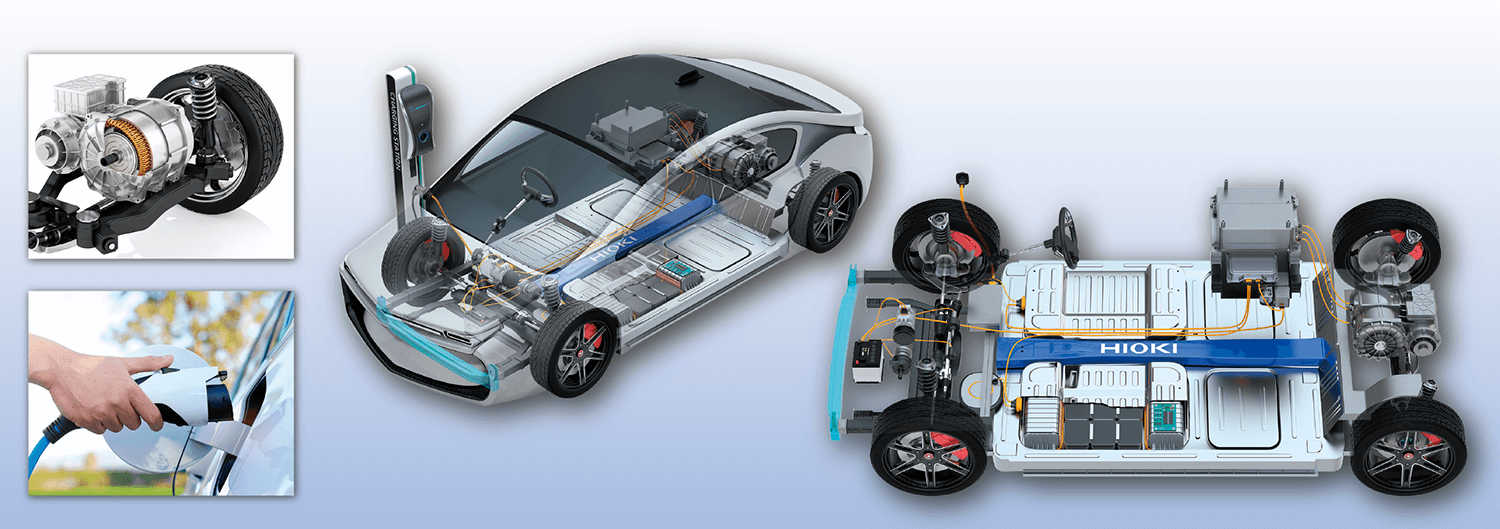

As environmental issues drive a transition to non-fossil fuels, the shift from vehicles powered by internal combustion engines (ICEs) to electric vehicles is accelerating, particularly in Europe and China. As part of that shift, development of battery electric vehicles (BEVs) is progressing worldwide. ICEs are powered by fossil fuels, whereas BEVs use electric energy stored in a battery to drive one or more motors.

Insulating materials, which prevent the flow of electricity, are essential in allowing BEVs to be used safely, and one important property of such materials is their insulation performance. BEVs are using higher and higher voltages to improve energy efficiency and shorten charging times, requiring insulating materials capable of accommodating those higher voltages.

In addition to high-capacity batteries and motors, BEVs require charging guns to charge their batteries and power control units (PCUs) to adjust drive motor output. These components use higher voltages and larger currents than conventional automotive parts. For example, under CHAdeMO, a widely known charging standard used in Japan,, vehicle batteries are charged at 500 V, a relatively high voltage. Individuals charging their vehicles must grip the charging gun with their hands and then insert it into the BEV’s charging port. Charging guns are made of resin that delivers excellent insulation performance (to prevent the flow of electricity) in order to avoid the risk of exposing users to the high voltage carried by the gun. Inside BEVs, components around batteries and the PCU are covered by an insulating material to ensure safety. In addition, motors are made with windings through which electricity flows, and those wires are covered with an insulating material known as varnish to ensure that the windings are insulated from each other.

Thus, many insulating materials are used in BEVs, and the importance of evaluating the insulation performance of insulating materials is increasing.

Issue: Need for measuring minuscule currents with a high degree of precision

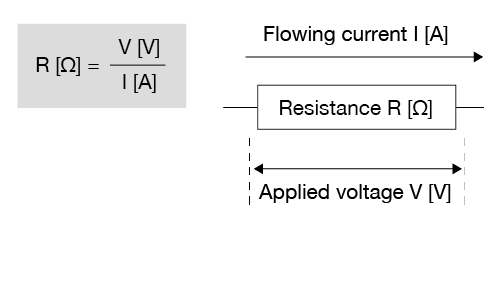

To verify BEV safety, manufacturers test the insulation performance of insulating materials. There are a number of test methods for doing so, but a common technique involves measuring the current that flows when a high voltage is applied to the material under test and then calculating the material’s resistance. Due to the adoption of ever-higher voltages in BEVs, materials are required to provide insulation performance capable of accommodating those higher voltages. Providing insulation means allowing the flow of almost no electricity, but a minuscule current will flow when a voltage is applied to an insulating material. To check the insulation performance of insulating materials, it’s necessary to accurately measure those minuscule currents.

The property of resistance, which can be expressed in ohms (Ω), indicates how readily electricity flows. Ohm’s law defines how voltage, current, and resistance are related. Insulation resistance is the resistance of an insulating material. In short, the property of insulation resistance indicates how much insulation an insulating material provides.

Solution: Super Megohm Meter SM7110/SM7120

Ideal for testing the insulation performance of insulating materials

The SM7110 and SM7120 Super Megohm Meters can measure minuscule currents with a high degree of precision. As BEVs adopt ever-higher voltages, they demand insulation performance capable of accommodating those voltages. The SM7110 and SM7120 can output voltages of up to 1000 V and 2000 V, respectively. Hioki offers an extensive line of measurement electrodes designed for various materials and applications.

Related standards: IEC 62631-3, IEC 60093, ASTM D257, JIS C2139-3, JIS K6911

Related Documents

Insulation Resistance Measurement Handbook

Applications:

Testing varnish impregnation state in a motor with an LCR meter