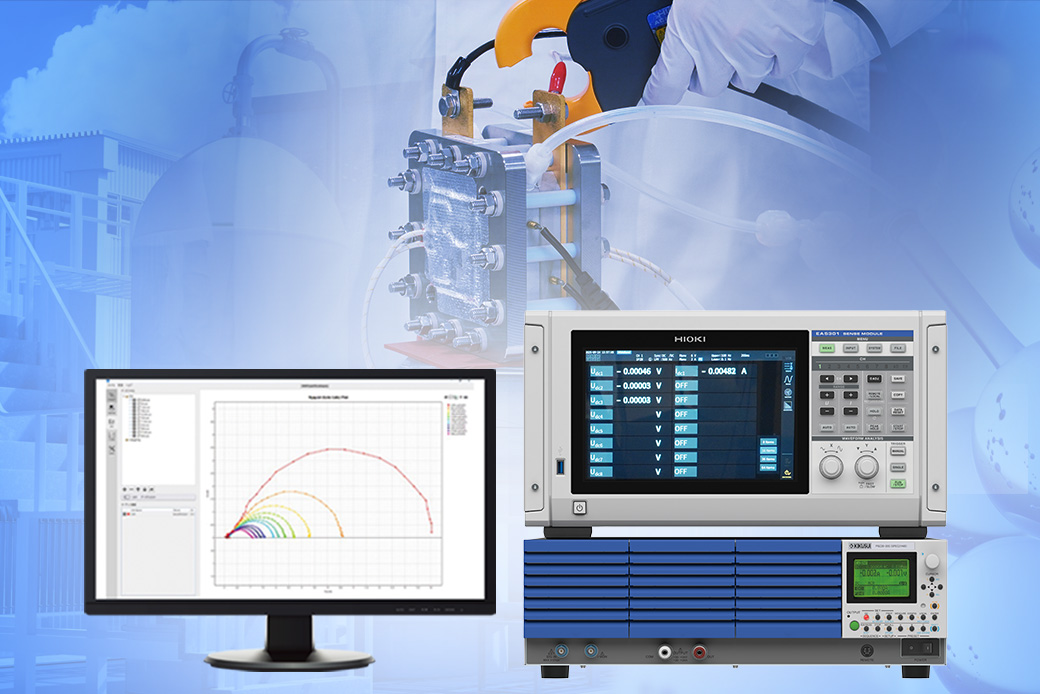

ALDAS-α : EIS MEASUREMENT SYSTEM

Advancing R&D of Water Electrolysis Cells and Fuel Cells

Fast and precision EIS measurement

NEW

Impedance measurement using electrochemical impedance spectroscopy (EIS) method is becoming increasingly important in research on water electrolysis cells, fuel cells, and co-electrolysis process.

Conventional current-voltage (I-V) measurements are commonly used to quantify the cell's overall performance. However, they fall short when it comes to diagnosing the specific underlying causes of performance degradation or change.

EIS is a technique that can quantitatively evaluate and separate complex phenomena within the cell. Analyzing data obtained from EIS measurements offers researchers to explore optimal operating conditions, predict cell lifespan, and verify the effects of changes in cell materials.

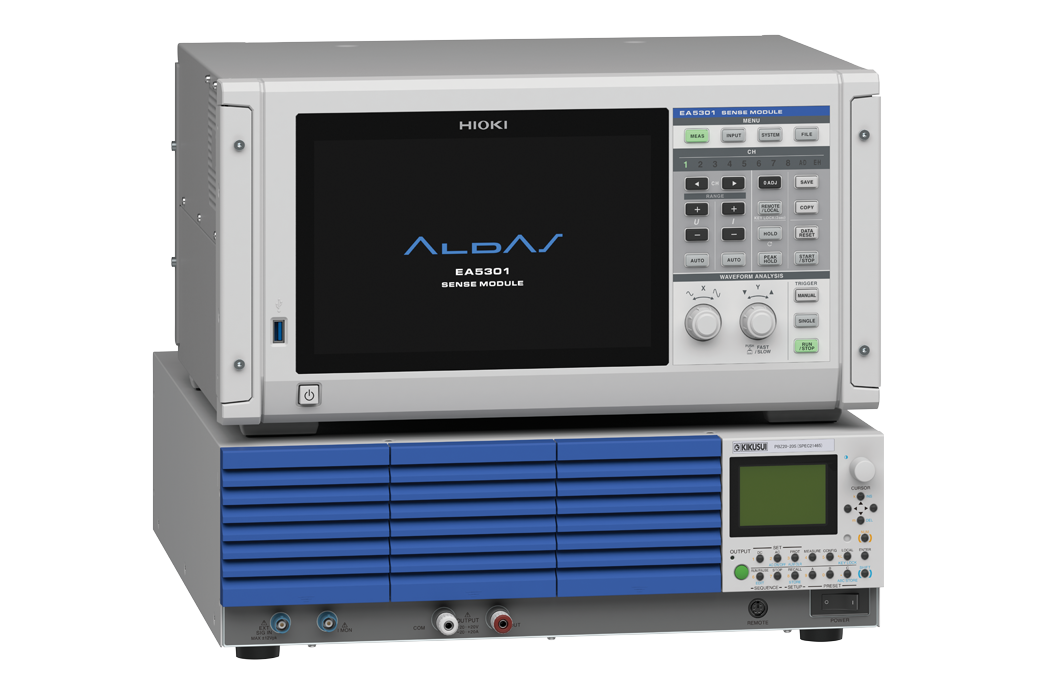

Featuring a high-precision current sensor, ALDAS-α delivers exceptionally accurate EIS measurements. It enables much faster cell research and evaluation than is possible with conventional equipment.

Key Features

- High-speed EIS measurement enables shorter test cycles

- Draws smooth curve from high to low frequencies

- Up to 20 A DC output without a booster

- Easy connection to existing EC and FC evaluation system

- Simultaneous measurement of up to 8 cells without any measurement delay

Model No. (Order Code)

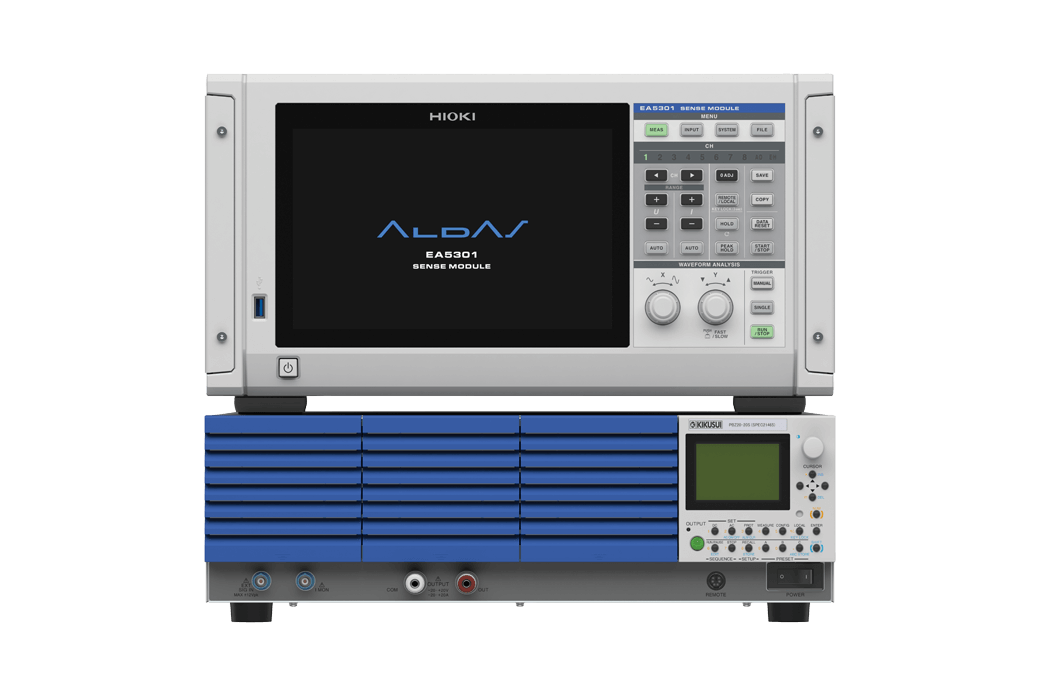

| EA5301-01 | SENSE module 1ch |

|---|---|

| EA5301-02 | SENSE module 2ch |

| EA5301-03 | SENSE module 3ch |

| EA5301-04 | SENSE module 4ch |

| EA5301-05 | SENSE module 5ch |

| EA5301-06 | SENSE module 6ch |

| EA5301-07 | SENSE module 7ch |

| EA5301-08 | SENSE module 8ch |

| EA5503 | SOURCE module |

| EA5703 | PC application software |

| L1100 | SENSE Cable |

High-speed EIS measurement shortens test cycles

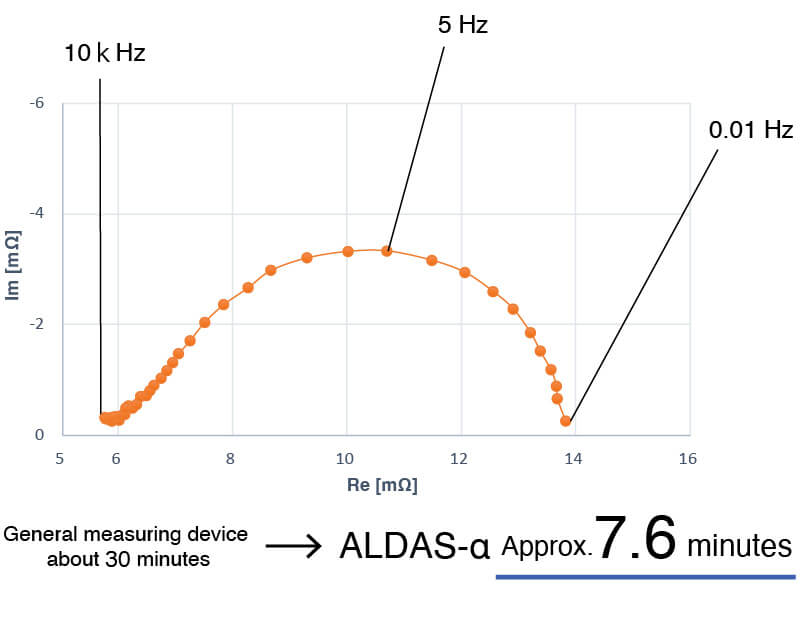

To observe the diffusion resistance region, impedance measurements must be extended to the low-frequency range. However, these measurements pose a challenge as they require a significant amount of time to complete. A typical electrochemical instrument, for instance, can take roughly 30 minutes to run a scan from 10 kHz to 0.01 Hz.

The ALDAS-α completes the same measurement in approximately 7.6 minutes*across 8 channels simultaneously. This advantage in speed and parallel measurement capability significantly improves throughput for evaluating electrolysis cells and fuel cell systems.

(Measurement conditions: 10 kHz to 0.01 Hz, 30 points, fast mode)

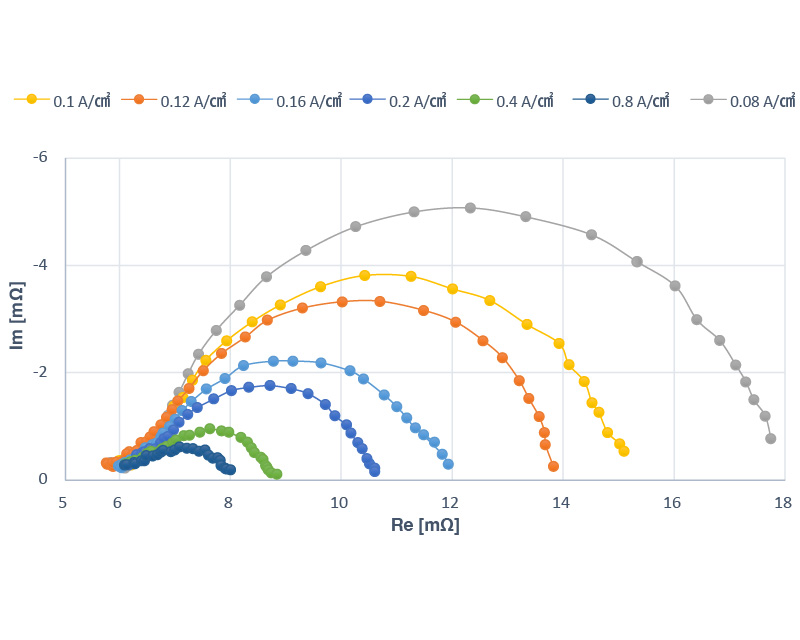

High-precision measurement with stability extending to the low-frequency range

Are you struggling with inconsistent EIS measurement results in the high-frequency and low-frequency regions?

ALDAS-α's advanced analog measurement technology and its special current sensor method reduce changes in measurements from the kHz range down to below 1 Hz. This produces smooth, low-variation Nyquist plots that simplify post-measurement analysis.

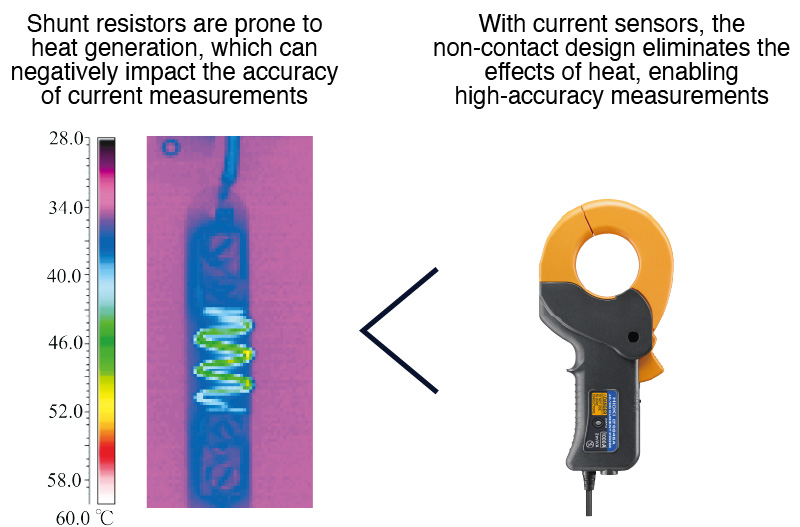

While many instruments use a shunt resistor method to measure current, this is susceptible to temperature drift. ALDAS-α uses a flux-gate current sensor instead. This completely avoids drift-related issues for stable, long-term measurements. Hioki's specialization in current sensor technology makes us the only manufacturer to achieve this level of precision with clamp-type current sensors.

Cell evaluation at high current densities

The demand for measuring impedance of high current density is increasing as we strive to enhance cell performance. ALDAS-α requires no booster power supply and can apply up to 20 A DC directly from the measurement system itself.

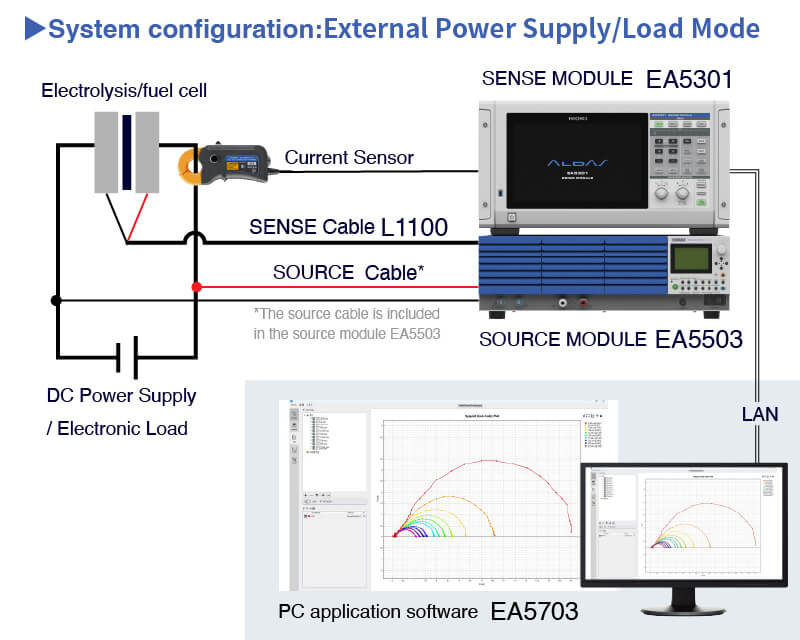

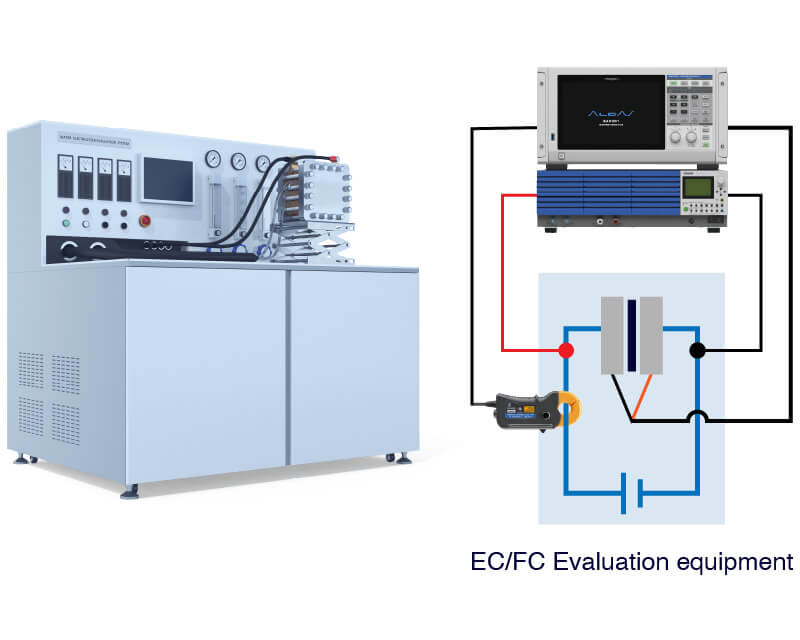

EIS measurements without modifying the EC/FC evaluation system

ALDAS-α is designed for effortless integration with your existing evaluation systems, connecting to DC power supplies and electronic loads without requiring any modifications. This seamless compatibility allows you to begin conducting EIS measurements immediately, drastically reducing the time from setup to results.

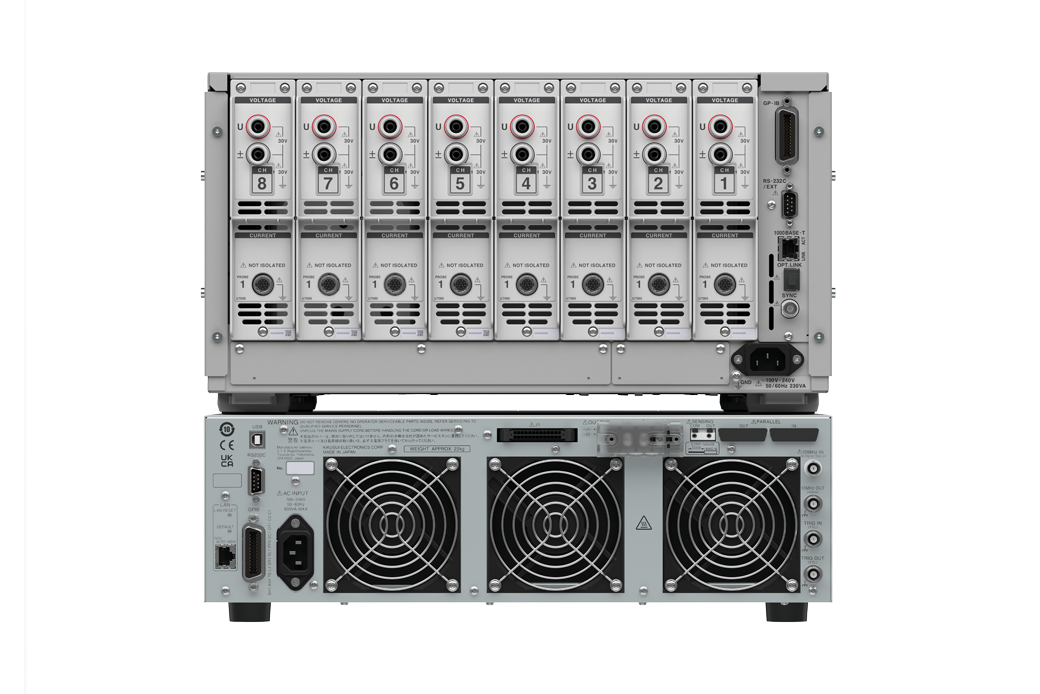

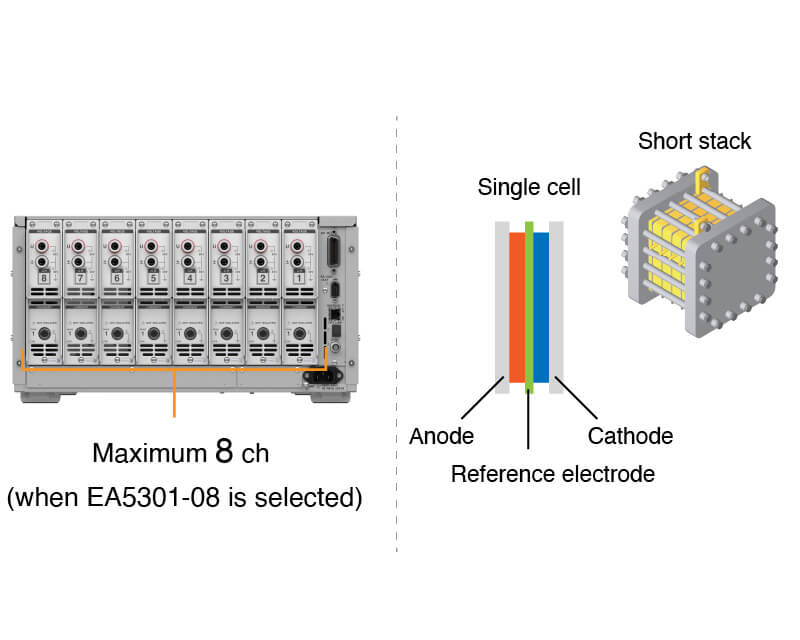

Simultaneous measurement of multiple cells for short-stack EIS evaluation

ALDAS-α excels at evaluating cell stacks by measuring each cell simultaneously. Essentially, the overall measurement time does not increase with the number of channels, allowing you to test a multichannel full stack as quickly as a single cell, significantly reducing total evaluation time.

This flexibility extends to detailed single-cell diagnostics. For any given cell, the instrument can simultaneously measure the impedance between the anode and reference electrode, the cathode and reference electrode, and the full anode-cathode pair, providing a comprehensive understanding of component performance.

Basic specification

| Measurement target | Electrolysis cell, Fuel cell, cell stack |

|---|---|

| Measurement parameters | Impedance (R,X,θ,Z), voltage (V), current (I) |

| Measurement modes | EIS Mode, Logging Mode |

| Display modes | Nyquist plot, Bode plot, logging plot |

| Measurement voltage | 60 mV to 20 V |

| Measurement current | 400 μA to 50 A (amperage depends on the current sensor used) |

| Load operating modes | Constant-current (CC) |

| Output power | For EC : 400 W (100 W if using an external DC power supply) For FC : 100 W |

| Output current | ±10 mA to 20.00 A (Output resolution: 0.01 A) |

| Measurement frequency range | 10 mHz to 100 kHz |

| Number of input channels | 1 to 8 Channels |

| Dimensions and weight | SENSE Module EA5301 (with 8 channels): approx. 430W × 221H × 361D mm (16.9W × 8.7H × 14.2D in.) (excluding protruding parts), approx. 12.7 kg (28.0 lb.) SOURCE Module EA5503: approx. 430W × 128H × 550D mm (16.9W × 5.0H × 21.7D in.) (excluding protruding parts), approx. 22.0 kg (48.5 lb.) (excluding cables) |

| Power supply | SENSE Module EA5301: 100 to 240 V AC, 50/60 Hz, 150 VA SOURCE Module EA5503: 100 to 240 V AC, 50/60 Hz, 900 VA |

| PC requirements | OS: Windows 11 Interface: wired LAN |

Current sensors (4)

Connection cable (1)

Small alligator clips, 2.2 m (7.2 ft.)