Oscilloscope or Power Analyzer? Make the Right Call

Accurate Power Measurement Beyond Oscilloscopes

Power measurement is a fundamental requirement for evaluating electrical systems. While oscilloscopes are widely used for waveform observation, debugging, and noise analysis, they are not designed to deliver the precision necessary for reliable power analysis. Accurate measurement is essential when evaluating efficiency, verifying compliance, or ensuring product quality. This application note explains the limitations of oscilloscopes in power measurement and introduces an alternative approach that provides the accuracy and confidence required in today’s demanding test environments.

Fig. 1. Oscilloscope

Measuring Inverter Efficiency with an 8-Channel Oscilloscope

Consider a typical power measurement setup: an inverter with DC input and three-phase AC output.

Required channels: total of 8

- 1 × DC voltage

- 1 × DC current

- 3 × AC voltage

- 3 × AC current

Required equipment:

- 8-channel oscilloscope

- 4 × high-voltage differential probes

- 4 × AC/DC current probes with dedicated power supplies

- PC and waveform analysis software

This setup becomes bulky, error-prone, and expensive. High-frequency components, switching noise, and varying frequencies complicate synchronization and analysis.

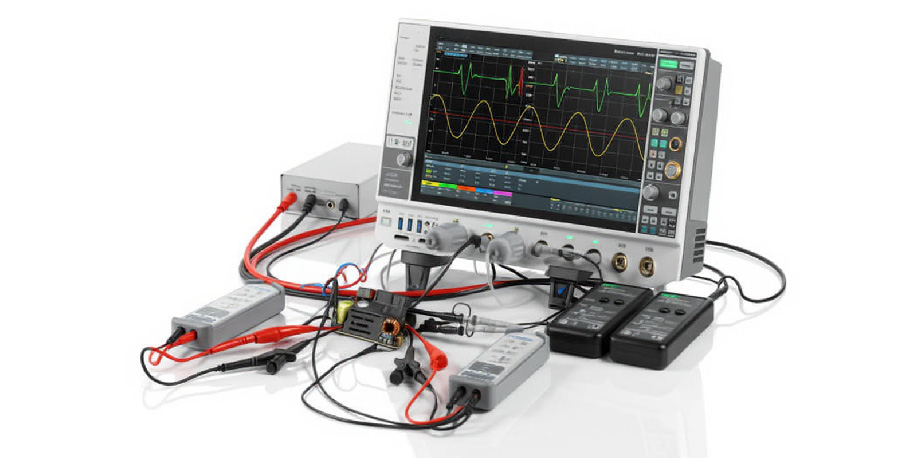

Fig. 2. Complex inverter setup with an oscilloscope (DC to 3-phase AC)

A Better Way: Simplified and Reliable with a Power Analyzer

In contrast, the Hioki PW4001 Power Analyzer simplifies this process:

- Measuring 4 systems of voltage + current = 4 power channels

- Direct high-voltage input without differential probes

- Safe and accurate current measurement via clamp-on sensors

- Real-time efficiency, power factor, harmonics, and energy display

- No post-processing required—just connect and measure

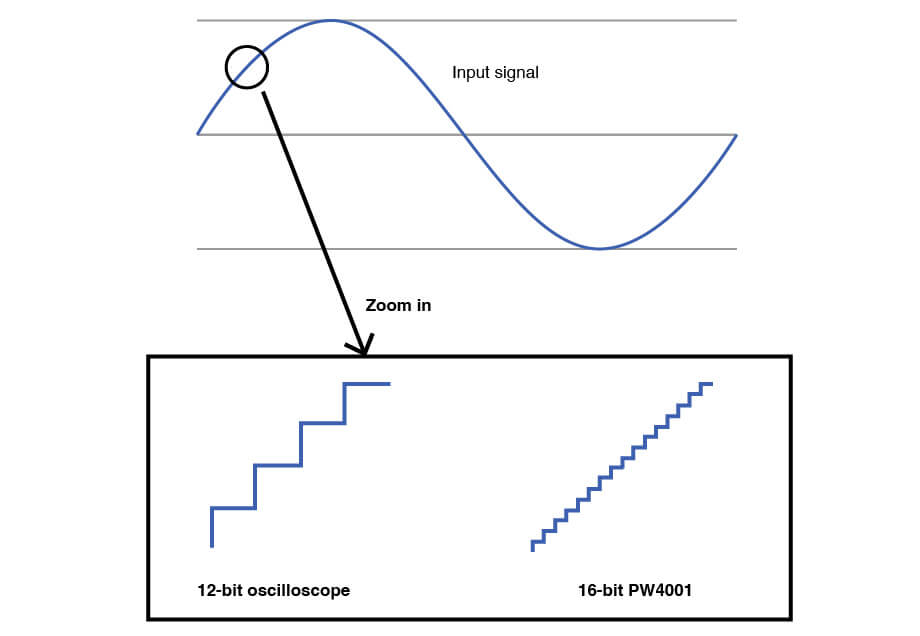

Accuracy & Resolution: The Specs Tell the Story

Let’s compare the measurement capability between a high-end oscilloscope and the PW4001:

| Feature | Oscilloscope | Hioki PW4001 |

|---|---|---|

| Resolution | 12 to 14 bits | 16 bits |

| Basic power accuracy | Not specified (approx. 5% of reading) | ±0.1% of reading*1 (basic ±0.03% of reading + sensor accuracy) |

| Basic voltage accuracy | Approx. ±2% of reading | ±0.03% of reading |

| Basic accuracy of current probes | Approx. ±1% of reading | ±0.07% of reading*1 (depends on sensor model) |

| Phase accuracy | Often unspecified | Auto-compensated |

- *1:When using the CT6833, CT6833-01, CT6834, CT6834-01

With oscilloscope-level accuracy, differences below 5% might go undetected. For applications like inverter efficiency, where 0.1% matters, the PW4001 is clearly superior.

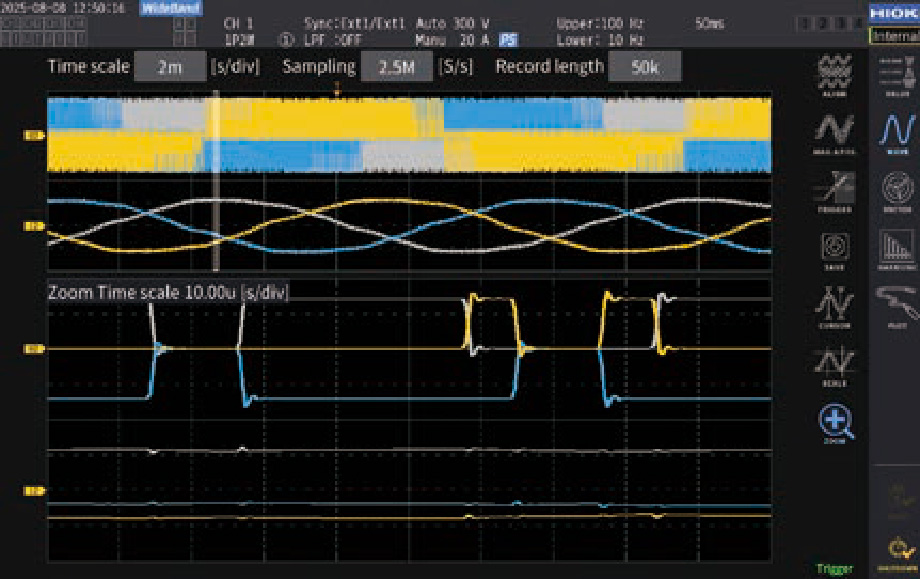

Still Want to See Waveforms? We Have That Too

The PW4001 samples waveforms just like an oscilloscope. With a 2.5 MHz sampling rate and 600 kHz analog bandwidth, it can easily capture PWM signals and even ringing. Additional features include:

- Triggered waveform capture (start recording exactly when specific signal events occur, like sudden voltage changes)

- Long-term waveform logging (500 s at 10 kS/s, 50 s at 100 kS/s)

- Simultaneous waveform and numeric display

Level & Event trigger capture transient waveform.

Level & Event trigger capture transient waveform. Zoom of PWM waveform.

Zoom of PWM waveform.

Harmonic analysis of inverter current.

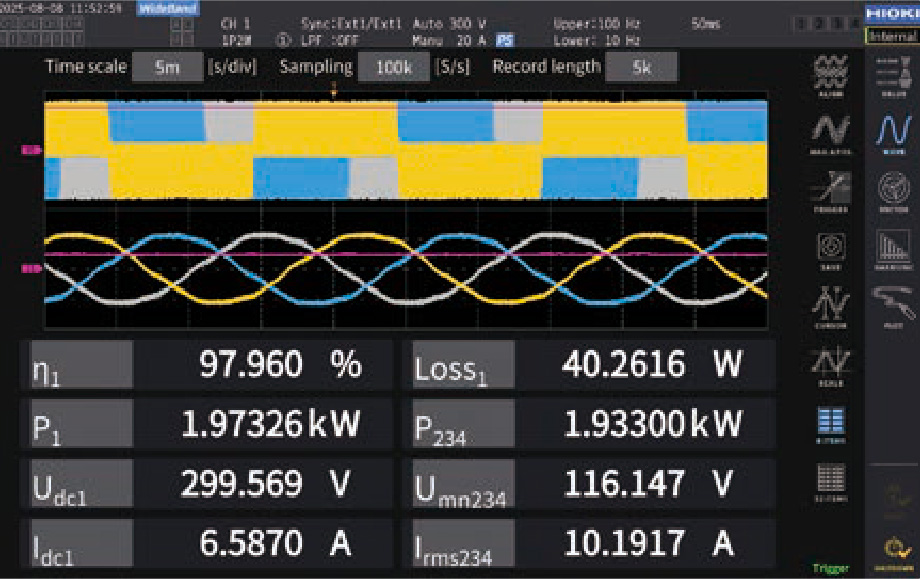

Harmonic analysis of inverter current. Inverter efficiency measurement value with waveform.

Inverter efficiency measurement value with waveform.

Fig. 3. Various measurements with the PW4001

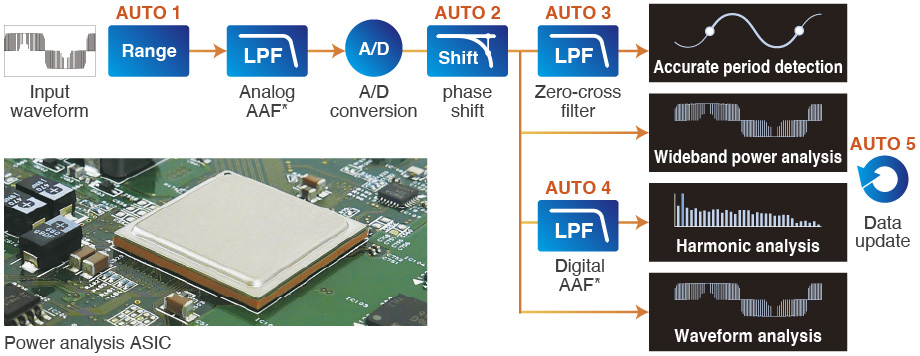

Signal Processing: the Hidden Advantage of Power Analyzers

Unlike oscilloscopes, the PW4001 divides input signals into five processing paths, each optimized for a specific purpose. Together, these ensure robust measurements—automatically, and without setup guesswork.

Five types of "AUTO" features ensure accurate and reproducible measurements

- Auto-ranging for voltage/current scaling

- Auto phase correction for current sensors

- Auto zero-cross detection for accurate cycle-based calculation

- Auto antialiasing processing for accurate harmonic analysis

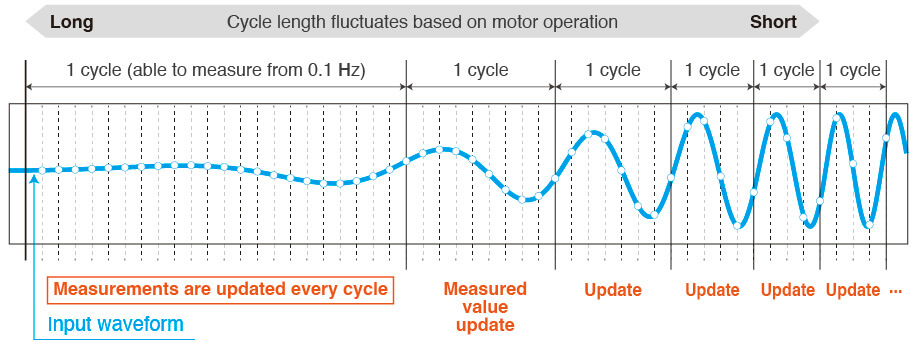

- Auto data update to detect power fluctuations in equipment whose frequencies fluctuate, from low to high frequencies

- *:AAF (anti-aliasing filter): This filter prevents aliasing errors during sampling.

Image of AUTO Data Update

Fig. 4. Five "AUTO" features ensure accurate and reproducible measurements

Time to Ask the Hard Question

If you're happy using your oscilloscope, that’s fine. But ask yourself: "Can I trust this power reading?"

When accuracy, compliance, and reproducibility are essential, so is the tool you use. Oscilloscopes are fantastic for waveform observation, noise tracing, and debugging. But if you want reliable values of power, efficiency, harmonics, and energy, the power analyzer isn’t a luxury—it's a necessity. With Hioki’s PW4001, you gain confidence in your data and the decisions you make.

Connect with a Hioki specialist to see how the PW4001 improves your work.

For detailed product information, please visit our website.

For a demonstration or consultation on a specific application, please contact us.