Minimizing PCB Processing Stress for Improved Reliability

Introduction

In the production of printed circuit boards (PCBs), mechanical stress during manufacturing processes can compromise product quality and reliability. Stress applied during cutting or assembly may lead to defects, such as cracked solder joints or damaged components, resulting in costly rework or product failures. Traditionally, manufacturers have relied on subjective methods like visual inspections or trial-and-error adjustments to mitigate these issues, but these approaches often lack precision and scalability.

This application note explores how high-precision strain measurement addresses these challenges by providing a quantitative approach to evaluate stress in PCB manufacturing. By using advanced measurement tools, manufacturers can optimize processing conditions, reduce defects, and enhance product reliability. Specifically, we introduce a solution using strain gauge sensors and Hioki's data acquisition systems to measure and analyze stress during PCB cutting, offering actionable insights for quality improvement.

Challenges in PCB Manufacturing

PCBs are typically produced from large sheets, which are later divided into individual boards to maximize material efficiency. The PCB’s manufacturing stages include mounting components, soldering (e.g., reflow), and cutting the sheet into smaller boards. The cutting stage, in particular, introduces significant mechanical stress, which can affect both the board and its mounted components. Excessive stress may lead to microcracks, component displacement, or latent defects that compromise long-term reliability.

Conventional approaches to managing these issues face several limitations:

- Subjective Adjustments:

Relying on operator experience for cutting parameters lacks consistency and reproducibility. - Inadequate Inspections:

Visual checks cannot detect internal stress or predict latent failures. - Time-Consuming Rework:

Identifying defects late in the process increases costs and delays production.

To overcome these challenges, a quantitative method for assessing stress in PCBs is essential. Strain measurement provides a direct way to monitor the mechanical impact of processing, enabling data-driven decisions to improve quality and efficiency.

Quantitative Strain Measurement Solution

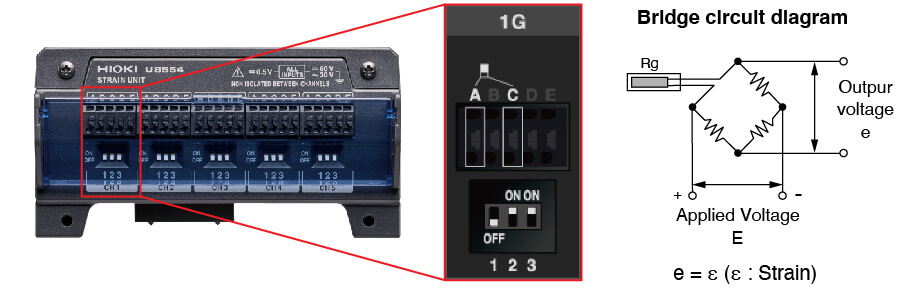

To address the challenges of PCB stress evaluation, a high-precision strain measurement system is recommended. This solution involves attaching strain gauge foil sensors (e.g., 2-axis strain gauge sensors from Kyowa Electronic Instruments) to the PCB and using a data acquisition system, such as the Hioki Memory HiLogger LR8450 with the Strain Unit U8554, to monitor strain signals during the cutting process. The collected data can be analyzed using Hioki’s complimentary Logger Utility software, available for download from the Hioki website, to gain detailed insights into stress levels.

Measurement Setup

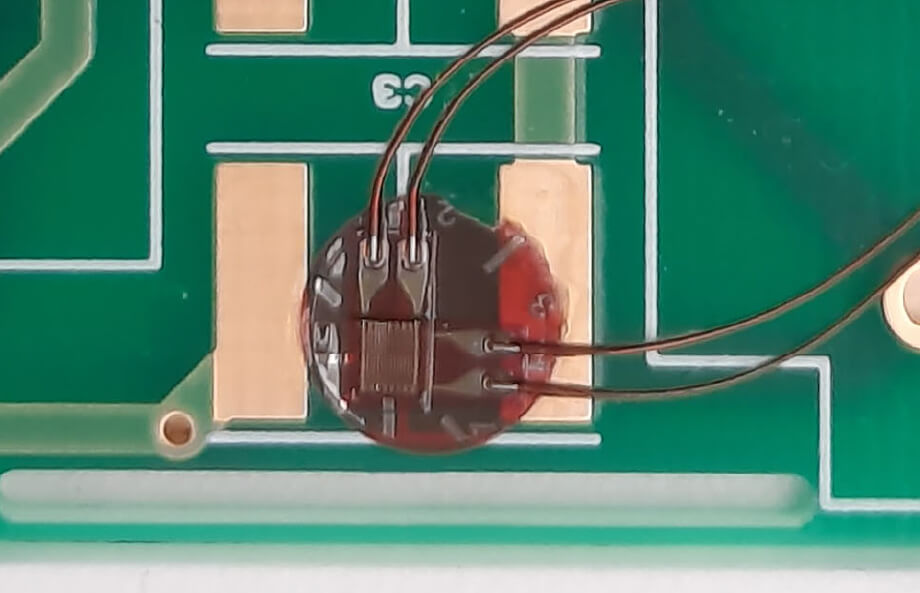

As an example, we will introduce a setup using a manual cutting machine where an operator feeds the PCB sheet into a rotating cutter. Strain gauges are affixed to the PCB at critical points, as shown in Fig. 1. For this application, a 1-gauge method (2-wire configuration) is used, with the strain sensor connected to the A and C terminals of the U8554. The unit’s internal bridge circuit is configured via a dip switch. In the test case, a single sheet containing two PCBs was evaluated, with strain gauges placed at two locations on each board to capture stress in multiple axes (Fig. 2).

Fig. 1. Detection using 2-axis strain gauges

Fig. 1. Detection using 2-axis strain gauges Fig. 2 Cutting machine used

Fig. 2 Cutting machine used

Measurement Results

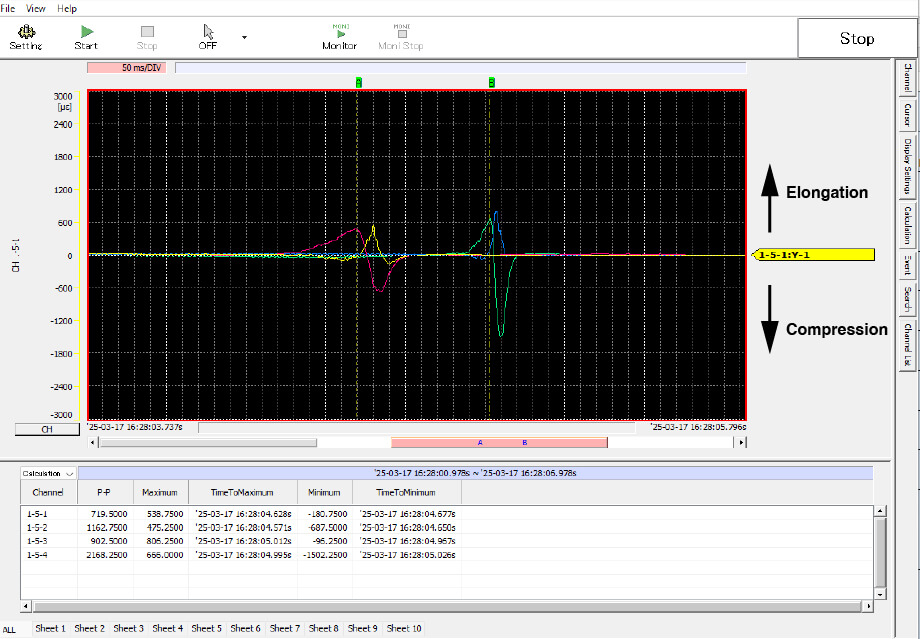

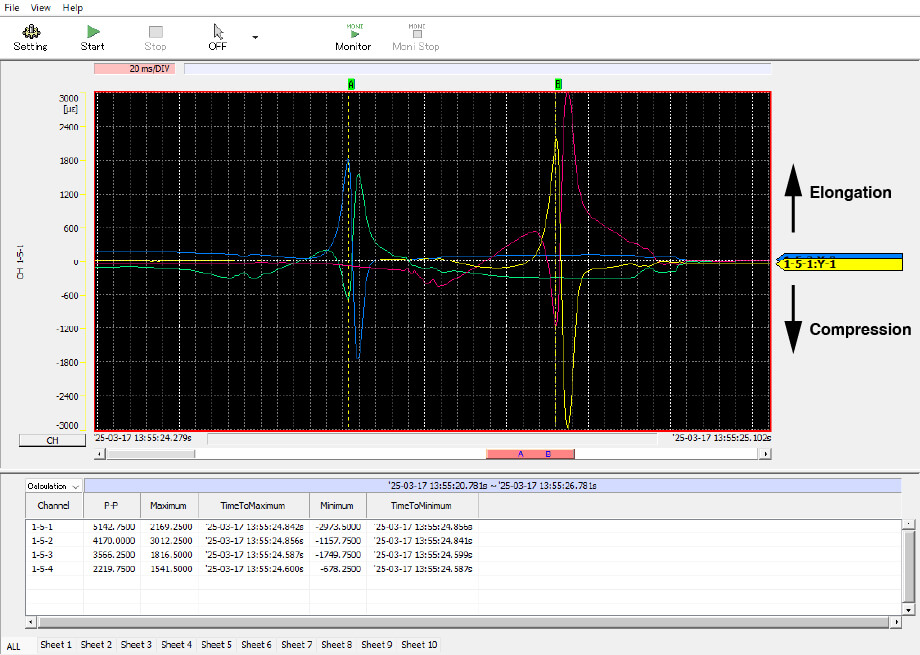

The strain measurement was conducted at two speeds: 201 mm/s and 332 mm/s. The results, analyzed via Logger Utility, are presented in Fig. 3 and Fig. 4.

Feed Speed 201 mm/s (Fig. 3):

- CH1 Y-1: 719 µε

- CH2 X-1: 1,162 µε

- CH3 Y-2: 902 µε

- CH4 X-2: 2,168 µε

Result: Lower strain levels, indicating reduced stress on the PCB.

Fig. 3 Logger Utility analysis for feed speed 201 mm/s

Feed Speed 332 mm/s (Fig. 4):

- CH1 Y-1: 5,142 µε

- CH2 X-1: 4,170 µε

- CH3 Y-2: 3,566 µε

- CH4 X-2: 2,219 µε

Result: Higher strain levels, suggesting increased stress and potential for defects.

Fig. 4 Logger Utility analysis for feed speed 332 mm/s

These results demonstrate that feed speed significantly affects the strain experienced by the PCB. Slower speeds (201 mm/s) result in lower strain, reducing the risk of damage. By quantifying strain, manufacturers can identify optimal cutting parameters to minimize stress and improve product quality.

Benefits of Strain Measurement

Using the Hioki LR8450 and U8554 for strain measurement offers several advantages:

- Objective Data:

Replaces subjective adjustments with precise, repeatable measurements - Defect Prevention:

Identifies stress-related risks early, reducing costly rework - Process Optimization:

Enables fine-tuning of cutting parameters for maximum reliability - Comprehensive Analysis:

Logger Utility provides detailed insights into stress distribution across the PCB

This solution empowers quality managers and technicians to make informed decisions, ensuring consistent production outcomes and enhanced PCB reliability.

Conclusion

Strain measurement is a powerful tool for addressing the challenges of stress in PCB manufacturing. By using the Hioki Memory HiLogger LR8450, Strain Unit U8554, and Logger Utility software, manufacturers can quantitatively evaluate processing stress, optimize cutting conditions, and reduce defects. This approach not only improves product quality but also streamlines production, saving time and costs.

For those seeking to enhance PCB manufacturing processes, Hioki’s strain measurement solutions provide a reliable, data-driven path to success.

For detailed product information, please visit our website.

For a demonstration or consultation on a specific application, please contact us using our contact form.

Download of software

The free software “Logger Utility” can be downloaded here.