Product Feb. 20, 2025

Hioki Launches Partial Discharge Detector ST4200 and High Voltage Multiplexer SW2001 for Reliable and High Efficiency Motor Production

Hioki Partial Discharge Detector ST4200 (left) and High Voltage Multiplexer SW2001(right)

Hioki Partial Discharge Detector ST4200 (left) and High Voltage Multiplexer SW2001(right)

Nagano, Japan, 20th February 2025 – Hioki E.E. Corporation is pleased to announce the launch of the Partial Discharge Detector ST4200 and High Voltage Multiplexer SW2001, designed to enhance the accuracy and efficiency of motor testing. These solutions address the increasing demand for reliable inverter-driven motors, fueled by the rapid expansion of electric vehicles (EVs) and industrial applications.

The Partial Discharge Detector ST4200 offers advanced capabilities for identifying partial discharge (PD) with precision and efficiency. Its dual-mode functionality, which includes AC Partial Discharge (ACPD) and Surge PD testing, enables early detection and mitigation of potential motor failures. Equipped with high-frequency current transformers (CTs), the ST4200 delivers robust noise-resistant performance, ensuring accurate PD detection even in high-interference production environments. Seamless integration with the High Voltage Multiplexer SW2001 simplifies system wiring, reducing cable complexity and improving measurement accuracy for a more streamlined testing process.

The High Voltage Multiplexer SW2001 is designed to complement the ST4200 by optimizing the testing workflow. With a flexible, scalable architecture offering multiple channel options, the SW2001 enables concurrent testing across multiple motors, significantly enhancing operational efficiency. Its highly reliable multiplexing design reduces downtime and supports increased production throughput, making it an ideal solution for high-volume motor manufacturing.

Development Background

The Global Shift Towards Carbon Neutrality

The transition to carbon neutrality has accelerated the adoption of electric vehicles (EVs) and energy-efficient industrial systems. In 2024, global sales of fully electric and plug-in hybrid vehicles surged by 25.6% year-on-year, reaching 1.9 million units in December alone1.

The Growing Demand for High-Efficiency Motors

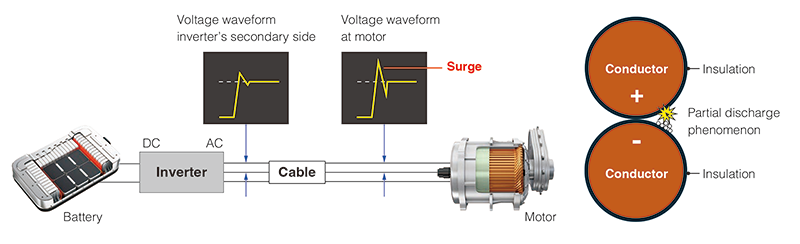

In regions like Europe, regulatory mandates now require high-efficiency motors classified as IE42 and above to enhance energy efficiency. The International Electrotechnical Commission (IEC) defines efficiency classes for electric motors, ranging from IE1 to IE4, with IE4 motors offering the highest efficiency, consuming less energy and resulting in lower operational costs compared to lower-classified motors. These motors are typically driven by inverter-based systems, which expose them to high surge voltages, increasing the risk of insulation failures.

The Rise of Advanced Power Semiconductor Technologies

Silicon carbide (SiC) and gallium nitride (GaN) power semiconductors enable high-speed, high-voltage switching, but they subject motors to surge voltages two to three times higher than their rated operating voltages. This can lead to latent defects turning into critical failures. The SiC and GaN market is projected to grow from $1.41 billion in 2024 to $11.08 billion by 2034, with a CAGR of 22.9%3.

Illustration of surge voltage and partial discharge phenomena in inverter-driven motor systems,highlighting insulation stress and potential failure risks

Illustration of surge voltage and partial discharge phenomena in inverter-driven motor systems,highlighting insulation stress and potential failure risks

The Importance of Partial Discharge (PD) Testing

PD testing is essential for detecting latent insulation defects before they result in motor failures. While AC high-voltage testing at 50/60 Hz has been the traditional standard, surge PD testing has emerged as a more effective method for simulating real-world operating conditions and identifying insulation weaknesses.

Challenges in High-Noise Environments

Despite its advantages, PD testing faces challenges in noisy environments, such as production lines, where traditional electromagnetic wave detection methods struggle with reproducibility. Additionally, modern production setups require efficient switching between high- and low-voltage measurements, adding complexity to system integration and control.

Hioki’s Solution for Reliable PD Detection

Hioki addresses these challenges with the Partial Discharge Detector ST4200, which utilizes high-frequency current transformer (CT) technology for reliable PD detection in noisy environments. Complementing this, the High Voltage Multiplexer SW2001 streamlines production inspections by reducing wiring complexity and maintenance costs, ensuring efficient operations with minimal high-voltage relay replacements.

Key Features

1. Dual-Mode Partial Discharge Detection

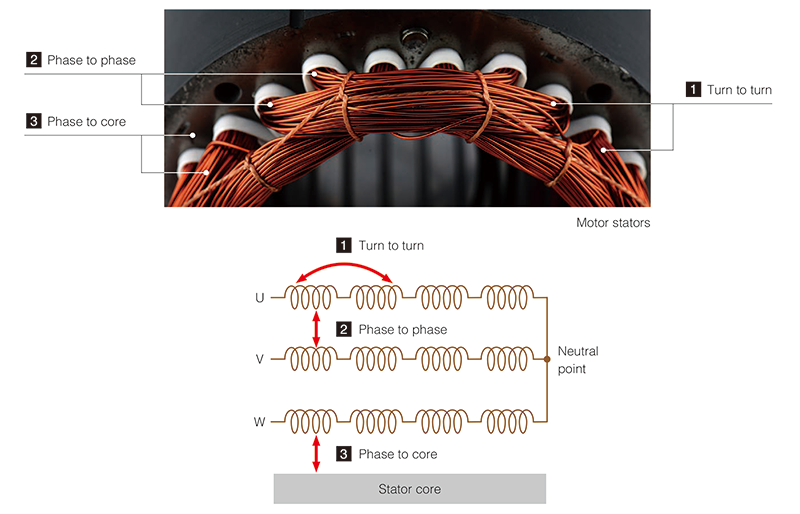

The ST4200 features two types of partial discharge detection: ACPD and Surge PD testing4, enabling better identification of latent defects to minimize catastrophic failures, such as fires. ACPD testing is the preferred method for assessing Phase-to-Phase and Phase-to-Core insulation; however, it is limited in closed-neutral Phase-to-Phase configurations. In such cases, Surge PD testing is employed to detect partial discharges effectively.

Diagram illustrating the three main types of partial discharge testing in motor stators: turn-to-turn, phase-to-phase, and phase-to-core, highlighting the critical pathways for assessing insulation integrity(right)

Diagram illustrating the three main types of partial discharge testing in motor stators: turn-to-turn, phase-to-phase, and phase-to-core, highlighting the critical pathways for assessing insulation integrity(right)

2. Noise-Resistant Partial Discharge Detection with High-Frequency CT

The ST4200’s high-frequency current transformer (CT) minimizes noise interference during partial discharge (PD) testing on production lines, addressing challenges associated with the electromagnetic wave detection method and reducing the impact of installation conditions on measurement results. This approach also enables reliable surge PD testing for finished motors.

3. Integration with the SW2001 High Voltage Multiplexer

To address noise challenges in complex testing environments, the ST4200 can be integrated into a multiplexer-based architecture with the SW2001. This design significantly reduces wiring complexity by consolidating multiple input signals and minimizing cable runs and interconnections. By mitigating potential noise sources such as electromagnetic interference (EMI), ground loops, and capacitive coupling, this approach ensures more accurate and reliable measurements.

4. Selectable Number of Channels for Your Testing Needs: 4, 8, 16, or 24-Channel Models

The SW2001 series provides customizable solutions with models available in 4, 8, 16, and 24 channels, tailored to meet diverse measurement requirements. Streamline motor inspections by connecting multiple instruments for six different tests: resistance, inductance, surge, hipot, insulation resistance, and partial discharge (ACPD and Surge PD). The multiplexer eliminates the need for frequent reconnections, making it ideal for parallel motor testing lines. The SW2001-24 model supports simultaneous testing of up to three three-phase motors, each equipped with two built-in thermistor temperature sensors.

Efficient motor testing with the SW2001 multiplexer, offering up to 24 channels for seamless multi-test integration, supporting simultaneous testing of three three-phase motors

Efficient motor testing with the SW2001 multiplexer, offering up to 24 channels for seamless multi-test integration, supporting simultaneous testing of three three-phase motors

5. Highly Reliable Multiplexing Design with Extended Operational Lifespan

The SW2001 incorporates durable high-voltage relays capable of safely switching high-voltage signals (up to 8 kV) with minimal leakage current. To ensure precise measurements, the system features a robust insulation design, optimizing clearance distances between relays and utilizing premium insulation materials for wiring. Additionally, the multiplexer design protects low-voltage test equipment by minimizing the risk of damage from stored energy in the motor windings.

Main applications

Partial discharge testing for EV and industrial motor production

The ST4200 and SW2001 provide comprehensive solutions for detecting insulation defects in motors used in electric vehicles (EVs) and industrial applications, ensuring high reliability and safety during production.

Motor test system building for electrical static tests

These systems enable seamless integration for electrical static tests, such as resistance, hipot, insulation resistance, and surge testing, streamlining motor testing processes and enhancing production efficiency.

Links

For more information, please refer to Partial Discharge Detector ST4200 and High Voltage Multiplexer SW2001 product pages.

Contact us

For inquiries such as quotes, demonstrations, and trial usage, please use Hioki’s contact form for a personalized reply from your closest or most appropriate Hioki representative.

-

Note:

- 1: Global electric vehicle sales up 25% in record 2024

- 2: New EU rules to boost energy efficiency of electric motors

- 3: SiC & GaN Power Semiconductor Market Size & - 2034

- 4: ACPD testing compliant with IEC 60270 and IEC 60034-27-1 | Surge PD testing compliant with IEC 61934 and IEC 60034-27-5

- The information provided is current as of the date of publishing.

- Please note that prices, specifications, and other information contained in this texts are subject to change without notice.

- The company names and product names used in this text are registered trademarks or trademarks of their respective companies.

About HIOKI

Established in 1935, HIOKI E.E. CORPORATION (TSE: 6866) has grown to become a world leader in providing consistent delivery of test and measuring instruments through advanced design, manufacturing, and sales and services. By offering over 200 main products characterized by safety and quality while meeting an expansive range of applications, we aim to contribute to the efficiency and value of our customers' work in research and development, production and electrical maintenance. Hioki products and services are available around the world through our extensive network of subsidiaries and distributors. For more information, visit us at www.hioki.com.